Gate Valve Non-rising Stem with High Quality from China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Gate Valve Description:

A gate valve, also known as a sluice valve, is a valve that opens by lifting a round or rectangular gate/wedge out of the path of the fluid. The distinct feature of a gate valve is the sealing surfaces between the gate and seats are planar, so gate valves are often used when a straight-line flow of fluid and minimum restriction is desired. The gate faces can form a wedge shape or they can be parallel. Gate valves are primarily used to permit or prevent the flow of liquids, but typical gate valves shouldn't be used for regulating flow, unless they are specifically designed for that purpose. Because of their ability to cut through liquids, gate valves are often used in the petroleum industry. For extremely thick fluids, a specialty valve often known as a knife valve is used to cut through the liquid. On opening the gate valve, the flow path is enlarged in a highly nonlinear manner with respect to percent of opening. This means that flow rate does not change evenly with stem travel. Also, a partially open gate disk tends to vibrate from the fluid flow. Most of the flow change occurs near shutoff with a relatively high fluid velocity causing disk and seat wear and eventual leakage if used to regulate flow. Typical gate valves are designed to be fully opened or closed.When fully open, the typical gate valve has no obstruction in the flow path, resulting in very low friction loss.

2. Main Features of the Gate Valve:

• Valve body cavity using non-toxic epoxy resin,both inside and outside flashboard completely is coated with rubber

• Free of water pollution

• High manufacturing accuracy

• High strength

• Environmental protection and energy saving

• Good visual effect

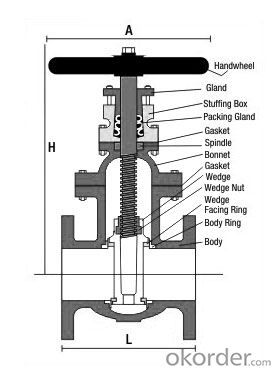

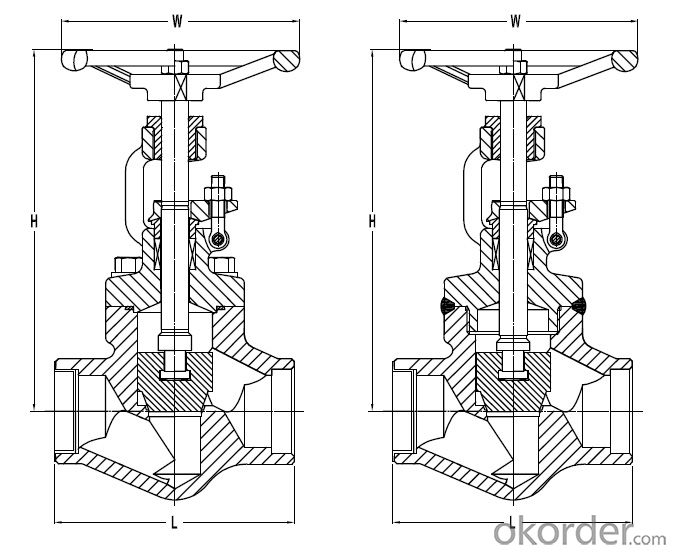

3. Images

4. Gate valve Specification

5.FAQ

1. What's are the characteristics of gate valve?

The distinct feature of a gate valve is the sealing surfaces between the gate and seats are planar, so gate valves are often used when a straight-line flow of fluid and minimum restriction is desired. The gate faces can form a wedge shape or they can be parallel.

2. What is the work principle of gate valve ?

The gate faces can form a wedge shape or they can be parallel. Gate valves are primarily used to permit or prevent the flow of liquids, but typical gate valves shouldn't be used for regulating flow, unless they are specifically designed for that purpose. Because of their ability to cut through liquids, gate valves are often used in the petroleum industry.

3. What is the structure?

Bonnets provide leakproof closure for the valve body. Gate valves may have a screw-in, union, or bolted bonnet. Screw-in bonnet is the simplest, offering a durable, pressure-tight seal. Union bonnet is suitable for applications requiring frequent inspection and cleaning. It also gives the body added strength. Bolted bonnet is used for larger valves and higher pressure applications.

- Q:What is the difference between the cut-off valve and the gate valve?

- Selection of stop valve:There are two ways to install the valve, one is the media flow from the top of the spool, the advantage is that when the packing is not under pressure, the pressure can be replaced before the valve packing, there is a long service life characteristics. Another is the media from the bottom of the spool into, and its shortcomings are driving torque is large, is 1 times above the flow, the stem by the axial force of large, easy to bend the stem. Generally suitable for small caliber manual stop valve, to stop the valve closed, the media acting on the spool of force is not greater than 350kg limit. Electric cut-off valve is generally used to enter the media from the top way.Selection of gate valve and stop valve:Valve than the valve structure is simple, better sealing, manufacturing and maintenance to be convenient; shortcomings are fluid resistance, power, and opening and closing efforts. Gate valve, stop valve are fully open, fully closed valve, suitable for making cut off, it is not suitable for use as regulating valve. The application process should pay attention to the characteristics of the valve when selecting. Small pipes and better sealing performance generally use cut-off valve; in the steam system and large diameter pipeline, due to fluid resistance is small, suitable for use gate valve.

- Q:Is the axial force and torque of the wedge gate valve the same?

- The sealing performance is good, the gate valve is not easy to be jammed when heated, and is suitable for the parts with frequent switches. B is suitable for steam, high temperature oil and gas medium. C is not suitable for easy coking medium.

- Q:What does the gate valve 150# mean? Is it stress PN? What's that, PN16 or?It's better to have some specific links, thanks!

- 150Lb (American Standard pressure value corresponding to the PN2.0)

- Q:Why does the centrifugal pump start and stop in the case of closing the gate valve?

- After the valve is closed to stop the cause of centrifugal pump outlet valve is closed to stop the pump to prevent the flow back into the pump, impeller, impeller in reverse, part of the mechanical seal in the pump pump impeller reversal will have adverse consequences, serious damage to the centrifugal pump, to close the valve after the shutdown.

- Q:What is the Z15T-16C letter of the gate valve?

- The Z class code indicates the type of gate valve, gate valve is the first letter of the alphabet. The gate is manual driving mode, 1 said the connection form of gate valve for connecting thread, 5 represents the structure form of gate valve for rigid single gate, T gate said lining material of copper alloy, 16 PN1.6MPa nominal pressure valve. C said the valve body material is carbon steel.

- Q:Which is more expensive, bronze gate valve or brass gate valve?

- The advantage of casting method is more obvious. The casting of stainless steel is much more difficult than that of brass.

- Q:Z45T-10 what kind of material is the gate valve?

- JB/T 308 regulation3.7.4 nominal pressure of less than 1.6Mpa gray cast iron valve body material code, in the type of preparation to be omitted.So its body material is gray cast iron, the sealing surface is copper alloy

- Q:The difference between flanged gate valve and common gate valve

- Flange gate valve and ordinary gate valve difference is that the flange gate valve of good quality, durable and easy to install, but the price is a little high, generally used for large pipelines. Common, also available, such as small caliber, easy to change places.

- Q:What is the difference between the cut-off valve and gate valve, the general will use the cut-off valve instead of gate valve

- Yes. Globe valves and gate valves are indeed common in certain piping and operating conditions.

- Q:Gate valve is gate valve, gate valve specifications, model code is generally what?

- Gate valve is not gate valve, gate valve does not have a fixed specific model

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Gate Valve Non-rising Stem with High Quality from China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords