Gate Valve DN350 Non-rising BS5163 Resilient Good Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Gate Valve Description:

A gate valve, also known as a sluice valve, is a valve that opens by lifting a round or rectangular gate/wedge out of the path of the fluid. The distinct feature of a gate valve is the sealing surfaces between the gate and seats are planar, so gate valves are often used when a straight-line flow of fluid and minimum restriction is desired. The gate faces can form a wedge shape or they can be parallel. Gate valves are primarily used to permit or prevent the flow of liquids, but typical gate valves shouldn't be used for regulating flow, unless they are specifically designed for that purpose. Because of their ability to cut through liquids, gate valves are often used in the petroleum industry. For extremely thick fluids, a specialty valve often known as a knife valve is used to cut through the liquid. On opening the gate valve, the flow path is enlarged in a highly nonlinear manner with respect to percent of opening. This means that flow rate does not change evenly with stem travel. Also, a partially open gate disk tends to vibrate from the fluid flow. Most of the flow change occurs near shutoff with a relatively high fluid velocity causing disk and seat wear and eventual leakage if used to regulate flow. Typical gate valves are designed to be fully opened or closed.When fully open, the typical gate valve has no obstruction in the flow path, resulting in very low friction loss.

2. Main Features of the Gate Valve:

• Valve body cavity using non-toxic epoxy resin,both inside and outside flashboard completely is coated with rubber

• Free of water pollution

• High manufacturing accuracy

• High strength

• Environmental protection and energy saving

• Good visual effect

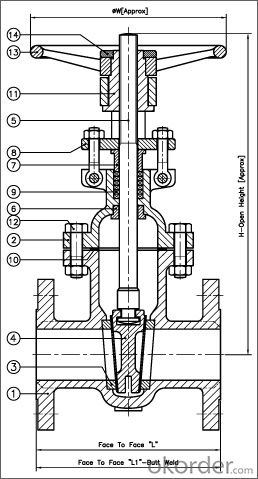

3. Images

4. Gate valve Specification

5.FAQ

1. What's are the characteristics of gate valve?

The distinct feature of a gate valve is the sealing surfaces between the gate and seats are planar, so gate valves are often used when a straight-line flow of fluid and minimum restriction is desired. The gate faces can form a wedge shape or they can be parallel.

2. What is the work principle of gate valve ?

The gate faces can form a wedge shape or they can be parallel. Gate valves are primarily used to permit or prevent the flow of liquids, but typical gate valves shouldn't be used for regulating flow, unless they are specifically designed for that purpose. Because of their ability to cut through liquids, gate valves are often used in the petroleum industry.

3. What is the structure?

Bonnets provide leakproof closure for the valve body. Gate valves may have a screw-in, union, or bolted bonnet. Screw-in bonnet is the simplest, offering a durable, pressure-tight seal. Union bonnet is suitable for applications requiring frequent inspection and cleaning. It also gives the body added strength. Bolted bonnet is used for larger valves and higher pressure applications.

- Q:The difference and use of gate valve and stop valve

- Medium flow is unrestricted.When opening fully, the sealing surface is eroded by the working medium smaller than the cut-off valve.The shape is relatively simple and the casting process is better.The valve is used in the system is relatively large, to close the gate off system; and the valve is used in the system is relatively small, and to adjust the flow quantity of the system, can not be closed gate and globe valves of different specifications for many kinds of occasions, the valve rod valve the dark bar gate valve, wedge gate valve, single valve, multi valve valve body structure is different, large volume.

- Q:What is the difference between gate valves Z41W-16R and Z41W-16P?

- According to JB/T308P stands for Cr-Ni stainless steelR stands for Cr-Ni-Mo stainless steelCr-Ni stainless acid resistant steel has CF8, CF3, F304, F304L, which applies to the medium of work, such as nitric acid oxidation acid.Cr-Ni-Mo stainless acid resistant steel has CF8M, CF3M, F316 and F316L, which is suitable for working medium, such as acetic acid and reducing acid.

- Q:What are the working principles of the electric gate valve?

- We see you what type of electric valve, is integral or ordinary type, if the overall type Denso took power on the line, is generally 380V and 220V power supply, and then according to their own needs and then open the signal line, in place and closing in place and remote control line, valve position feedback signal the commonly used 4~20ma over torque protection fault signal.

- Q:Which is the most expensive, check valve and gate valve?

- In the case of DN50 Z15T-16 DN50: screw valve 46.200 thread copper bar gate valve Z15T-16 DN50 52 Z45F-16 DN50 97 flange valve flange valve rod Z44T-10 DN50 169 Z45T-116 DN50 flange valve dark bar 173 thread swing check valves DN50 52.090 thread straight type check valve DN50 57.280 flange screw check H44T DN50 129 flange valve lift check valve H41T-16 DN50 124

- Q:Will the water supply and drainage to wear civil air defense gate valve, the use of bright rod or dark rod?

- 3, soft sealing rubber lining valve plate size uniform, interchangeable. Therefore, the soft sealing gate valve will be the direction of development, but also the water supply industry is willing to adopt a valve.

- Q:What is wire feed gate valve? What do you say in French?

- It should be the wire gate valve. Refers to the valve body with internal thread or external thread, and pipe thread connection. Also called thread valves, threaded valves, valves within the toothFlange gate valve is connected to the flange gate valve, this connection is the most common wayThe main difference is the connectionI only know their English, I'm sorry I can't help youBox thread valveFlange valve

- Q:What is the standard for ductile iron gate valve set?

- The valve material name, specifications and price according to the facts that the valve rod input line.

- Q:What are the meaning of the cast rigid gate valves z41h-16c?

- According to the provisions of the JB/T 308-2004 valve type programming method:Z== gate valve4== flange connection1== rigid single gateH== sealing surface material: Cr13 stainless steel16== pressure rating: 1.6MPaC== body material: carbon steel

- Q:What does the gate valve SZ45X-1.0 stand for?

- Z- stands for gate valves, 4 for flange connections, 5 for wedge wedge single gate, X for rubber seals, and 1.0- for PN1.0MP

- Q:Is the gate valve flanged?

- The most commonly used gate valves are threaded connections, flanged connections, and welded connections.Like the outer thread connection, the clamp connection, the card sleeve is seldom used.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Gate Valve DN350 Non-rising BS5163 Resilient Good Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products