GATE VALVE AWWA/ ANSI NON-RISING STEM RESILIENT SEATED DUCTILE IRON

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 9999 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Standard or Nonstandard: | Standard | Structure: | Gate | Pressure: | Low Pressure |

Power: | Manual | Material: | Casting | Temperature of Media: | Normal Temperature |

Media: | Water | Port Size: | Standard | Place of Origin: | China (Mainland) |

Model Number: | Z1703111 | Brand Name: | CMAX | Application: | General |

Body: | DI | Disc: | DI+EPDM | Stem: | Stainless Steel |

Stem Nut: | Bronz | Bonnet Gasket: | EPDM | Nut: | WCB |

Bolt: | WCB | Bonnet: | DI | O Ring: | EPDM |

Gland: | DI |

Packaging & Delivery

Packaging Details: | plywood case or fumigation wooden case |

Delivery Detail: | 30 days |

AWWA/ANSI 250Psi Non-Rising Stem Metel Seat Gate Valve

Features

Replaceable O-ring

Low torque operation

Rubber encapsulated wedge

Clockwise closing direction

Fusion bonded epoxy coated inside and outside

Product color:Bule RAL 5017

Temperature:33-125 °F/0.6-52 ℃(AWWA C509)

Technical Specification

Design:AWWA C515/C509 250Psi

Face to Face:ANSI B16.10

Flanges:ANSI B16.1 Class125

Work Pressure:3-12inch;200Psi

16-30inch:150Psi

Hydraulic test :AWWA C509

Seat :250Psi

Shell:500Psi

- Q:What is the difference between Z41X gate valve and Z45X gate valve?

- All flange soft sealing gate valve, but 41X is Ming bar, 45X is dark pole

- Q:Analysis of the advantages of elastic seat sealing gate valve?

- When the elastic seat sealing gate valve is closed, the sealing surface can be sealed only by the medium pressure, that is, the sealing surface of the flashboard is pressed to the valve seat of the other side only by the medium pressure to ensure the sealing of the sealing surface, which is self sealing.

- Q:Z41T one 10 gate valve and Z44T one, 10 gate valve difference

- Z41T one, 10 is single gate, Z44T one, 10 is double gateAccording to the provisions of the JB/T 308-2004 valve type programming method:Z== gate valve4== connection: flange type1== structure: Rigid single gate4== structure: Rigid double gateT== sealing surface material: copper alloy10== pressure rating: 1.0MPa

- Q:Please tell the specific specifications and specifications of the gate valve and advise the principle of management cooperation Thank you

- There is mail sent me, send you a specific

- Q:Why does the fire hydrant box in the air defense area need to be added with gate valves?

- Code for design of basement for civil air defence GB50038The installation and installation of the protective valve on the water supply line of the 6.2.13 air defense basement shall comply with the following requirements:OneWhen the water supply pipe from the entrance into, should be set up in the inner protective sealing door;

- Q:What's the meaning of the gate valve model z41x 16Q?

- Gate valve (Z) flange connection (4) wedge type single gate (1) rubber soft seal (X) -16 pressure) (Q)

- Q:What gate valve is the J41H-150LBDN100 gate valve?

- Its closing principle is to rely on the valve bar pressure, so that the valve sealing surface and seat sealing surface close together, to prevent the circulation of media. The cut-off valve is divided into three kinds: straight through type, right angle type and direct current type oblique stop valve.

- Q:The main question is, what are the functional differences in which case?

- The gate (gate valve) is a gate opening and closing parts, RAM direction of motion perpendicular to the direction of the fluid, valve can only be fully open and fully closed, can not be adjusted and the throttle gate valve. The direction of motion perpendicular to the direction of the fluid, valve can only be fully open and fully closed, can not be adjusted and the throttle.Gate valve advantages: 1, fluid resistance is small,.2, opening and closing more labor-saving,.3, medium flow unrestricted, not disturbed flow, do not reduce pressure,.4, simple shape, structural length is short, manufacturing process is good, a wide range of applicationsValve shortcomings: 1, between the sealing surface is easy to cause erosion and abrasions, maintenance is more difficult,.2, big size, open need some space, opening and closing time is long,.3, the structure is more complex

- Q:Yes, soft sealing gate valve can reach 25 kilograms, Fujian light valve company has this type of soft sealing gate valveAnonymous browsing | 28 times

- Soft seal butterfly valve seal is good, but can only withstand up to 16 pressure, or the plastic can not stand. A short period of time is OK, and it's also related to the workmanship and quality of the factory. The quality is poor.

- Q:What is the difference between gate valve and gate valve? Is it the same valve?

- Gate valve and gate valve are 2 kinds of valves, do not feel like a long name is the same kind, please look at Baidu maps introduced manufacturers.

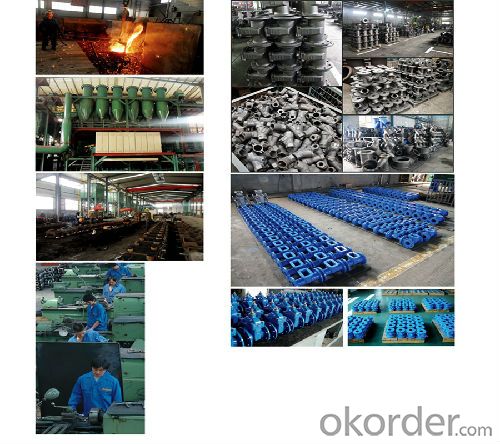

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

GATE VALVE AWWA/ ANSI NON-RISING STEM RESILIENT SEATED DUCTILE IRON

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 9999 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords