Gate valve Api609 ansi125/ansi150 with Good Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Gate Valve Description:

A gate valve, also known as a sluice valve, is a valve that opens by lifting a round or rectangular gate/wedge out of the path of the fluid. The distinct feature of a gate valve is the sealing surfaces between the gate and seats are planar, so gate valves are often used when a straight-line flow of fluid and minimum restriction is desired. The gate faces can form a wedge shape or they can be parallel. Gate valves are primarily used to permit or prevent the flow of liquids, but typical gate valves shouldn't be used for regulating flow, unless they are specifically designed for that purpose. Because of their ability to cut through liquids, gate valves are often used in the petroleum industry. For extremely thick fluids, a specialty valve often known as a knife valve is used to cut through the liquid. On opening the gate valve, the flow path is enlarged in a highly nonlinear manner with respect to percent of opening. This means that flow rate does not change evenly with stem travel. Also, a partially open gate disk tends to vibrate from the fluid flow. Most of the flow change occurs near shutoff with a relatively high fluid velocity causing disk and seat wear and eventual leakage if used to regulate flow. Typical gate valves are designed to be fully opened or closed.When fully open, the typical gate valve has no obstruction in the flow path, resulting in very low friction loss.

2. Main Features of the Gate Valve:

• Valve body cavity using non-toxic epoxy resin,both inside and outside flashboard completely is coated with rubber

• Free of water pollution

• High manufacturing accuracy

• High strength

• Environmental protection and energy saving

• Good visual effect

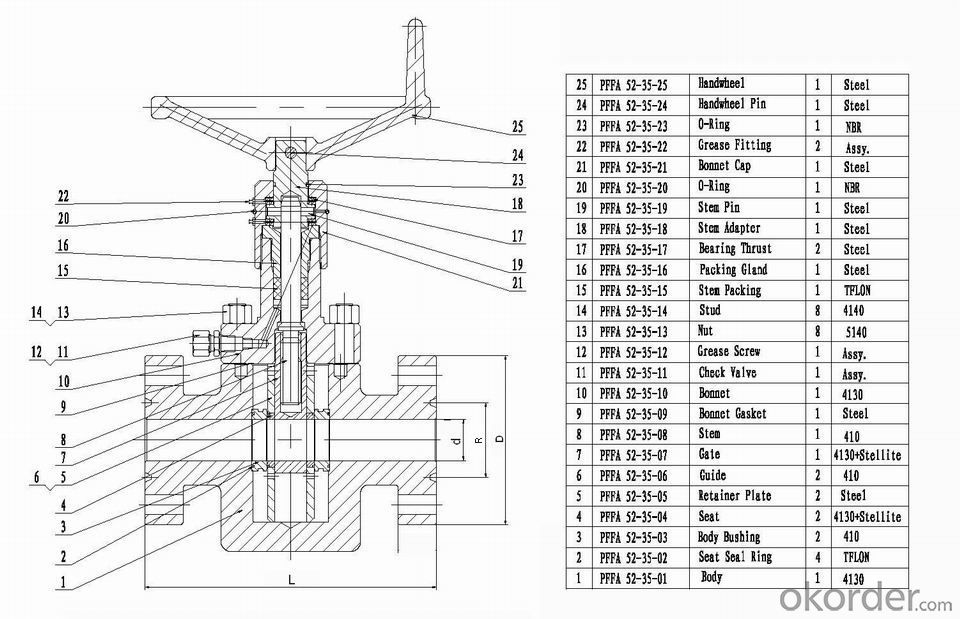

3. Images

4. Gate valve Specification

5.FAQ

1. What's are the characteristics of gate valve?

The distinct feature of a gate valve is the sealing surfaces between the gate and seats are planar, so gate valves are often used when a straight-line flow of fluid and minimum restriction is desired. The gate faces can form a wedge shape or they can be parallel.

2. What is the work principle of gate valve ?

The gate faces can form a wedge shape or they can be parallel. Gate valves are primarily used to permit or prevent the flow of liquids, but typical gate valves shouldn't be used for regulating flow, unless they are specifically designed for that purpose. Because of their ability to cut through liquids, gate valves are often used in the petroleum industry.

3. What is the structure?

Bonnets provide leakproof closure for the valve body. Gate valves may have a screw-in, union, or bolted bonnet. Screw-in bonnet is the simplest, offering a durable, pressure-tight seal. Union bonnet is suitable for applications requiring frequent inspection and cleaning. It also gives the body added strength. Bolted bonnet is used for larger valves and higher pressure applications.

- Q:How about the valve?

- Now, there is an office in Beijing, valve enterprises in the valve, a lot of online ah, you click to see if you want information

- Q:How does the valve close?

- Special wrench or socket.Turn clockwise to the end。The handle should be closed groove and the coincidence place.

- Q:Tell me the exact address, or the phone number in the market. Where is the industrial zone (the valve) in Hefei? Please help, thank you

- Hardware city inside, on the opposite side of the East Second Ring Guoqiang steel market

- Q:Can other valves be used instead of 10?

- An elbow, an outer wire, screw down the joint of the hose, the elbow is joined together.

- Q:There is a rectangular hole in the valve core, which the heating company repairman gives to the bolt. Rest assured, I do not want to heating, but my indoor temperature is low, I suspect that the repairman mischief, deliberately give me lower temperature

- The heating valve refers only to a radiator system accessories, is a type of valve, the valve commonly used heating system on the market is mainly divided into: gate valve, ball valve, safety valve, balance valve, globe valve, regulator valve, relief valve, pneumatic control valve.

- Q:Is the heat jacketed valve fitted with flanged flanges?

- Insulation valve is the standard valve, just in order to ensure the link bolt flange to super space, usually a large ball than normal level, such as the use of the path is DN80 flange, flange is DN100, so is the standard, but the size of flange connecting with other valves are not the same.

- Q:Look at the flow chart, some of the valves are marked with FV, and some are marked with XV. What does that mean?And what do you mean by the Cv value on the valve nameplate?I hope the heroes give a clear explanation ah, it is best to give an introduction of this knowledge of the web site oh.Thank again.

- FV or LV on the flow chart, which represents the instrument bit number, FV is flow valve, and LV is level valve.The valve on the nameplate CV value, it is a measure of the size of the valve flow, it is the concept of 40 - 60 degrees Fahrenheit in the water, the pressure drop of 1 psi, in a valve opening per minute flow through the valve (U.S. gallons).

- Q:What kind of valves are best used for sand drain valves?

- Suzhou ATW Valve Co. Ltd production of sealing ball valve, Suzhou ATW Valve Co., according to the condition of solid particles, long-term research and in practice, and achieved good results in the condition of solid particles. You can try!

- Q:How to better maintain the valve?

- We should keep the valve cleanWe should regularly check and maintain the integrity of the valve the other components. As a fixed hand wheel nut fell off, to be filled and can not manage, otherwise it will grind the valve stem upper garden square, gradually lost with the reliability, and even can not startWe do not rely on the valve support other heavy objects, do not stand in the valveThe stem, especially the threaded part, to regular cleaning, the dust has been soiled should be replaced with a new lubricant, because the dust contains hard debris, easy to wear thread and stem surface, affect the service life

- Q:What are the key valve enterprises in China? Mainly in those areas?

- How much? I don't know. It depends on what valve you need. Hebei iron and steel Wenzhou, needle valve Funing, Anhui Tongdou valve. Do not want to buy a high price of Shanghai valve, look at your specific needs

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Gate valve Api609 ansi125/ansi150 with Good Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products