Galvanized Steel Sheet Price,Silicon Steel Sheet of Transformer

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Galvanized Steel Sheet Price,Silicon Steel Sheet of Transformer

Quick Details

| Standard: | AISI, ASTM, BS, DIN, GB, JIS | Grade: | steel sheet, SGCC, DX51D, Q195, Q215, Q235, Q345 | Thickness: | 0.3-115mm |

| Place of Origin: | Tianjin, China (Mainland) | Brand Name: | hot dipped galvanized steel sheet | Model Number: | 201, 202, 301, 321, 304, 304L, 316, 316L, 309S, 310S, 410, 430 ect |

| Type: | Steel Plate | Technique: | Hot Rolled | Surface Treatment: | Galvanized |

| Application: | truck frames, brackets, crane booms,shipbuilding industry | Special Use: | High-strength Steel Plate | Width: | 1000-2000mm |

| Length: | 2000-6000mm or as your requirements | name: | galvanized steel sheet | MOQ: | 25T |

| Certification: | ISO9001:2008 |

Packaging & Delivery

| Packaging Details: | silicon steel sheet of transformer:Standard export seaworthy package. |

| Delivery Detail: | 15-20 days after receiving your deposit or L/C |

Specification

Thickness | 0.3 mm-115mm |

Width | 1000mm, 1219mm, 1240mm, 1500mm, 1800mm, 2000mm as customer request |

Length | 2000mm-6000mmor as customer request |

Standard | AISI, ASTM, BS, GB, DIN, JIS, etc |

Material | 201, 202, 301, 321, 304, 304L, 316, 316L, 309S, 310S, 410, 430, etc |

Surface | Coated(2B, BA, 8K, No. 4 No.1) Galvanized or bare |

Packaging | Standard export sea-worthy packing |

Technique | Hot rolled / cold rolled |

Delivery time | 10-25days |

Supply ability | 3,0000MT per month |

Payment terms | L/C, T/T, D/P |

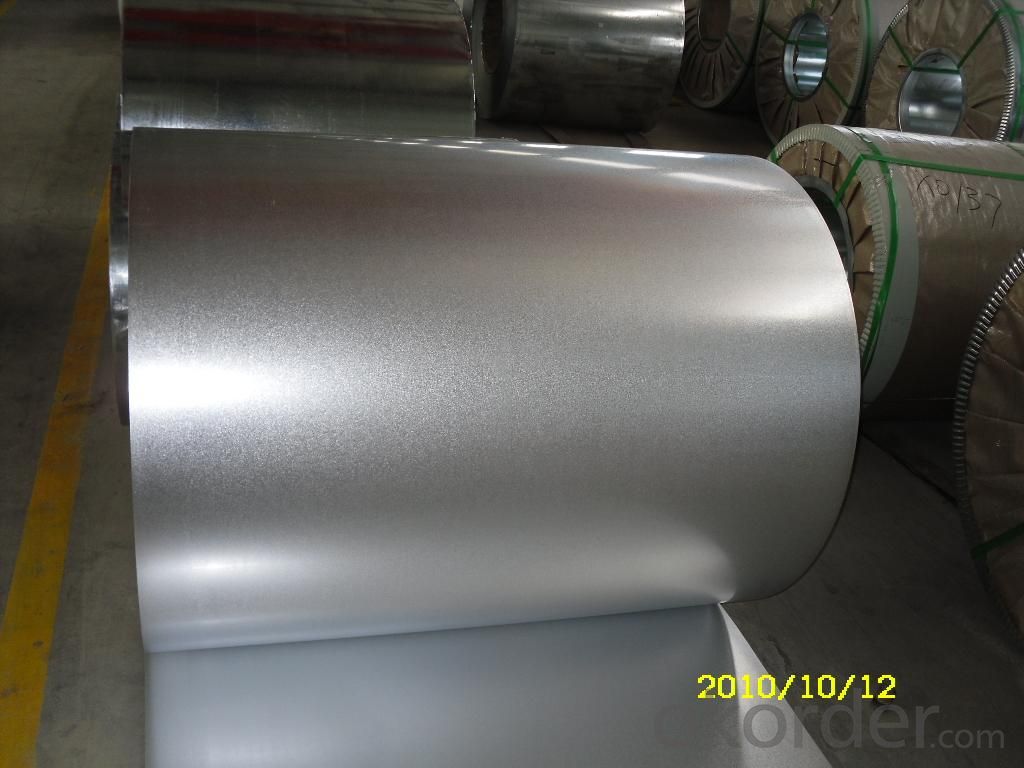

Picture

- Q:Can steel sheets be used for conveyor belts?

- Yes, steel sheets can be used for conveyor belts. Steel sheets are often used as the base material for conveyor belts due to their strength, durability, and resistance to high temperatures. They provide excellent support for carrying heavy loads and are commonly found in industries such as mining, automotive, and manufacturing.

- Q:What are the different sheet metal forming techniques for steel sheets?

- Steel sheets can be shaped into desired forms and structures using various techniques for sheet metal forming. Below are some common techniques used for steel sheets: 1. Bending: To create angles, curves, or complex shapes, the sheet is bent either manually or with the help of machines like press brakes. 2. Stretch forming: This technique involves stretching and forming the sheet over a mold or die, especially for large and curved components. 3. Deep drawing: By using a punch and a die, the sheet metal is formed into desired shapes, often used for cylindrical or box-like structures such as cans, pots, or automotive components. 4. Roll forming: The sheet metal is passed through a series of rollers to gradually shape it into the desired form. This technique is commonly used for producing long and continuous shapes like rails, tubes, or channels. 5. Spinning: A spinning tool is used to rotate the sheet metal against a mandrel, shaping it into cylindrical or conical shapes such as lampshades or cookware. 6. Embossing: This technique involves stamping a pattern or design onto the sheet metal to create a raised or recessed surface. It is commonly used for decorative purposes or to enhance the structural integrity of the sheet. 7. Hydroforming: Hydraulic pressure is utilized to shape the sheet metal into complex forms, often employed in the creation of automotive components like car body panels or exhaust systems. These examples illustrate the wide range of sheet metal forming techniques available for steel sheets. The choice of technique depends on the desired shape, complexity, and specific requirements of the application.

- Q:Can the steel sheets be easily cleaned?

- Certainly, steel sheets can be effortlessly cleaned. Renowned for their durability and low-maintenance nature, steel sheets can be swiftly wiped down with a damp cloth or sponge accompanied by mild soap or detergent. In the case of stubborn stains or grime, a non-abrasive cleaner is recommended. Moreover, steel sheets exhibit exceptional resistance to rust and corrosion, rendering them well-suited for diverse settings and ensuring hassle-free maintenance in the long term.

- Q:What are the different hardness levels available for steel sheets?

- The different hardness levels available for steel sheets range from soft to very hard, with common options being mild steel, hot-rolled steel, cold-rolled steel, and stainless steel. These hardness levels determine the steel's ability to resist deformation and wear, making it suitable for various applications based on the required strength and durability.

- Q:Are steel sheets resistant to graffiti?

- Yes, steel sheets are generally resistant to graffiti due to their smooth and non-porous surface, making it difficult for spray paint or other graffiti materials to adhere. Additionally, steel sheets can be easily cleaned or repainted if graffiti does occur.

- Q:Can steel sheets be used for manufacturing automotive parts?

- Yes, steel sheets can be used for manufacturing automotive parts. Steel offers excellent strength, durability, and formability, making it a preferred material for various automotive components such as body panels, frames, and chassis.

- Q:What are the different types of steel sheet finishes for decorative purposes?

- There are several different types of steel sheet finishes that are commonly used for decorative purposes. These finishes are applied to the surface of the steel sheet to enhance its appearance and provide a desired aesthetic effect. Some of the most popular steel sheet finishes for decorative purposes include: 1. Brushed Finish: This finish is achieved by brushing the surface of the steel sheet with a fine abrasive material, usually in a straight line pattern. It creates a smooth, satin-like appearance and is often used for architectural and interior design applications. 2. Mirror Finish: Also known as a polished finish, this finish creates a highly reflective surface that resembles a mirror. It is achieved by mechanically polishing the steel sheet and is commonly used in decorative applications such as furniture, lighting fixtures, and signage. 3. Patterned Finish: This finish involves embossing or etching a pattern onto the surface of the steel sheet. It can be achieved through various techniques, such as stamping, laser engraving, or chemical etching. Patterned finishes provide a decorative and textured appearance and are often used in applications like elevator panels, wall cladding, and decorative screens. 4. Colored Finish: Steel sheets can also be coated with a colored finish to add vibrancy and enhance their visual appeal. This can be achieved through processes such as powder coating, which involves applying a dry powder to the steel sheet and then curing it to create a durable, colored finish. Colored finishes are commonly used in architectural applications, including building facades and signage. 5. Antique Finish: This finish is designed to give the steel sheet an aged or weathered look, resembling antique metal. It is achieved through various techniques such as chemical treatments, patinas, or distressing. Antique finishes are often used in decorative applications to create a rustic or vintage aesthetic. These are just a few examples of the different types of steel sheet finishes available for decorative purposes. Each finish offers a unique appearance and can be customized to suit specific design preferences. The choice of finish depends on the desired look, application, and the level of durability required for the project.

- Q:Can steel sheets be painted or coated?

- Yes, steel sheets can be painted or coated.

- Q:Are steel sheets suitable for interior wall cladding?

- Yes, steel sheets are suitable for interior wall cladding. They offer durability, strength, and a modern aesthetic, making them a popular choice for commercial and residential interiors.

- Q:How are steel sheets protected during transportation by sea?

- Steel sheets are protected during transportation by sea through various measures such as applying corrosion-resistant coatings, packing them in moisture-proof and weather-resistant materials, securing them with appropriate lashing and bracing, and using specialized shipping containers or vessels equipped with proper ventilation and humidity control systems. These measures ensure that the steel sheets remain intact, free from rust, and undamaged throughout the sea voyage.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Galvanized Steel Sheet Price,Silicon Steel Sheet of Transformer

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords