Galvanized Steel Sheet Gi Coil for Building Materials

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Basic Info.

Model NO.:ST010

Standard:ASTM, JIS, GB, AISI, DIN

Steel Grade:Q195

Certification:ISO, SGS, BV, RoHS, IBR

Surface Treatment:Galvanized

Technique:Cold Rolled

Application:Packing,Gutter Ect.

Edge:Mill

Stock:Stock

THK:0.13-3mm

Width:10mm-550mm

Inner Diameter:200mm to 600mm

Export Markets:Global

Additional Info.

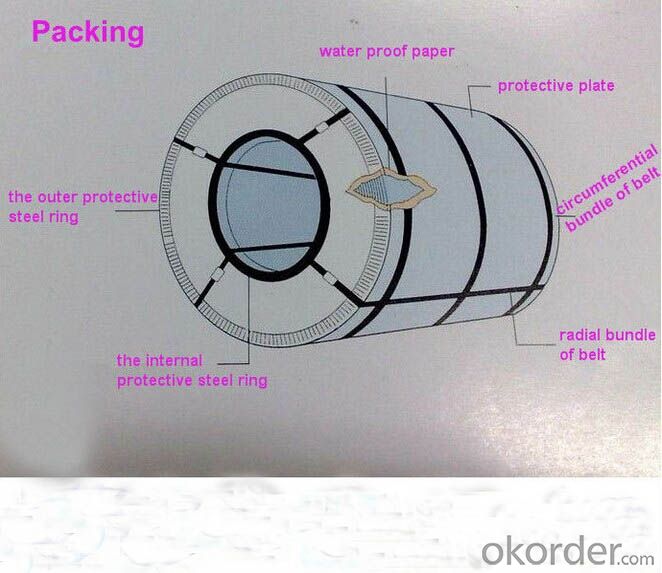

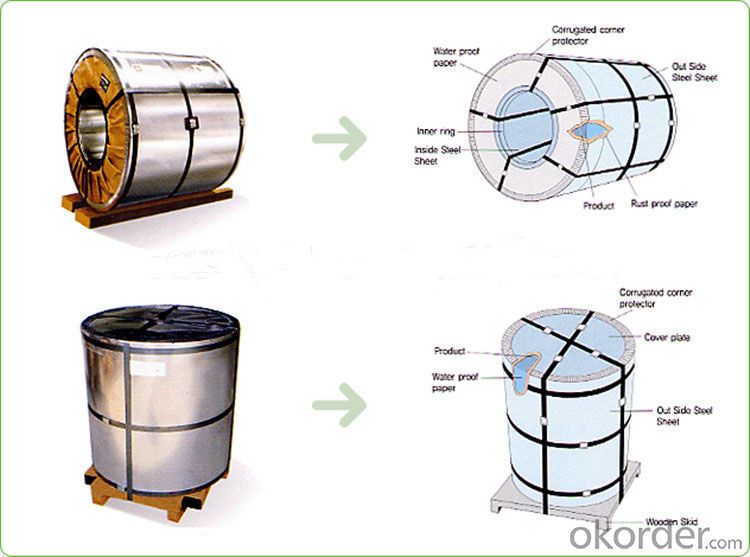

Packing:Wood Pallets

Standard:OEM

Origin:China

Production Capacity:30000 Tons Each Month

Product Description

1. Thickness: 0.18-1.5mm;

2. Width: 50-914mm;

3. Hardness: 380MPa-450MPa;

4. Specification: 0.35*50, 0.4*45, 0.4*65, 0.4*68, etc.;

5. Surface waxed and edges deburred;

6. Standard: As per buyers' specifications among Q195-Q345B in the GB standard;

7. Package: Inner is protect humidity-proof waw paper, medium is plastic film, outer is sackcloth or compound paper packing, or as per customer's requirements.

| Standard | AISI, ASTM, BS, DIN, GB, JIS, etc |

| Grade | SGCC, DX51D, DX53D, DX54D, etc |

| Thickness | 0.14-2.5mm |

| Width | less than 600mm |

| Inner Diameter | 508/610mm |

| Coil Weight | 1.5-4.0T |

| Zinc Coating | 60g/m 2 -180g/m 2 |

| Spangle State | regular spangle, small spangle, big spangle, non-spangle |

| Surface Treatment | Chromate, Oil, Lacquer Seal, Phosphating, etc |

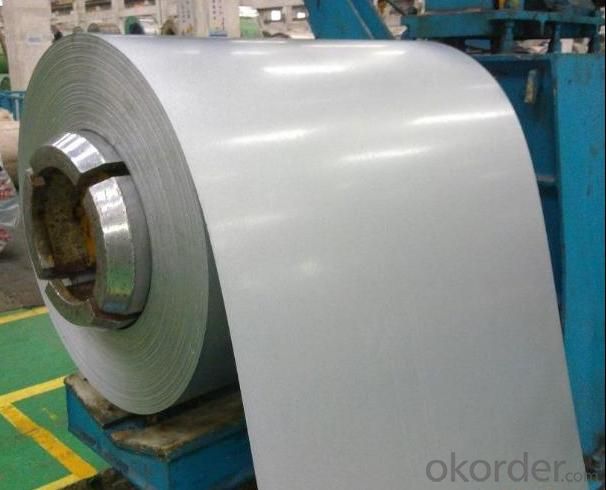

Product show:

Package:

FAQ:

1. What is the minimum order quantity ?

Our MOQ is 50mt for each size. And we will consider to give more discount if you make big order like 1000 tons and more. Further more, the more appropriate payment term your offer the better price we can provide.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

4.What is the validity of your quotation?

Normally 7 days.

5.What is your advantage?

24 hour quick response /Customer oriented/ Credit foremost/ Top quality Excellent

- Q:How do steel coils contribute to the manufacturing of electrical equipment?

- Steel coils play a crucial role in the manufacturing of electrical equipment due to their unique properties and versatility. Firstly, steel coils are used in the production of transformer cores, which are essential components in electrical equipment. The magnetic properties of steel make it an ideal material for transformer cores as it allows for efficient energy transfer and reduces energy losses. The coil shape of the steel enables it to generate a magnetic field that facilitates the transformation of voltage levels, thus ensuring the proper functioning of electrical equipment. Moreover, steel coils are commonly used in the production of motors and generators. These devices rely on magnetic fields to convert electrical energy into mechanical energy and vice versa. The coil shape of the steel allows for the creation of electromagnetic fields, which are necessary for the operation of motors and generators. Additionally, the strength and durability of steel ensure that the coils can withstand the high temperatures and mechanical stresses that are often encountered in electrical equipment. Furthermore, steel coils are utilized in the construction of electrical conductors, such as wires and cables. These conductors enable the transmission of electricity from power sources to various electrical devices. Steel, with its high electrical conductivity, ensures efficient power transmission while also providing mechanical strength and protection from external factors such as corrosion and wear. The coil shape of steel wires further enhances their flexibility, making them suitable for various applications in electrical equipment manufacturing. Overall, steel coils contribute significantly to the manufacturing of electrical equipment by providing the necessary magnetic properties for transformer cores, enabling the generation of electromagnetic fields in motors and generators, and facilitating efficient power transmission in electrical conductors. Their versatility, strength, and durability make steel coils an indispensable component in the production of reliable and high-performance electrical equipment.

- Q:How are steel coils used in the production of signage?

- Steel coils are commonly used in the production of signage as they provide a durable and versatile material for creating sturdy sign structures. The steel coils are typically shaped and cut into desired sizes and shapes, allowing for the construction of various types of signage, such as billboards, road signs, and building signs. The steel's strength and resistance to corrosion ensure the longevity of the signage, making it suitable for outdoor use. Additionally, steel coils can be painted or coated with vinyl to add color and graphics, enhancing the visual appeal of the signs.

- Q:Is it just because brass is reloadable? But what makes it reloadable? What does brass bring to the equation that the steel cased ammo can't do?

- Brass is slightly softer than annealed steel. Both can be reloaded, once or maybe even twice. But STEEL has a tendency to WORK HARDEN, becoming brittle. Which is why it's used for tools and other applications where work hardening is a plus. It's actually designed to do that. Brass does not work harden, because it is a different sort of metal. That's the main reason.

- Q:What are the different types of steel grades used for coil production?

- There are various types of steel grades used for coil production, including carbon steel, stainless steel, high-strength low-alloy (HSLA) steel, and advanced high-strength steel (AHSS). Each grade has its own unique properties and is chosen based on the specific requirements of the application.

- Q:i have purchased a high dollar Martin guitar and i was wondering if there are many people out there that have used steel string acoustics for classical and flamenco guitar playing.otherwise i will need a nylon stringeror.. uld i put nylon strings on an old yamaha steel string guitar that i have?

- Guitars built for either nylon or steel strings are constructed differently. You will have problems putting nylon strings on a steel stringed guitar and visa verse. I say NEITHER is a good idea. If I were in your shoes, I would walk on line or to a guitar store and purchase a nylon stringed guitar. That's what I did years ago and now I am hooked. I got a second hand Takamine A/E that work just fine for a couple hundred and then just a yr or so ago I got a brand new one, an EC132C and I just LOVE it. As my skills improve I plan on upgrading to a custom built acoustic only with a cutaway. I like cutaways but not the electronics. I never plug into my amp hardly at all. Yamaha makes nylon guitars too VERY cheap and real good tonal quality, I was VERY impressed with one that I played. I upgraded my tuners on my new Takamine to Schaller 16:1 and put the old Takamine tuners on that Yamaha and it's a really nice little guitar to kick around on when I am at that person's place.

- Q:Cooling bed generally a part of the steel rolling mills

- In the USA, a steel cooling bed is called a run-out table. It consists of a series of steel rolls. Each roll may be individually driven by an electric motor. DC motors are often used with parallel armatures connected to a common armature voltage control speed control unit. The roll speed is controlled to match the speed of the incoming sheet of steel so that the steel does not slide or skid on the surface of the rolls. Field trim resistors help to assure that the speed and torque of rolls is matched. A centering mechanism may be used to keep the steel in the center of the table. Water may be sprayed from the top and bottom to aid cooling. After an initial run out table, the strip of steel may be cut on-the-fly into individual sheets which pass to another table that is running slightly faster to separate the sheets. Alternatively, the steel may be coiled at the end of the table.

- Q:What are the different methods of galvanizing steel coils?

- There are primarily three methods of galvanizing steel coils: hot-dip galvanizing, electrogalvanizing, and continuous galvanizing. Hot-dip galvanizing involves immersing the steel coils in a bath of molten zinc, which forms a protective coating. Electrogalvanizing uses an electric current to deposit a layer of zinc onto the steel surface. Continuous galvanizing is a process where the steel coil is continuously passed through a bath of molten zinc to achieve galvanization. These methods provide varying levels of protection against corrosion and are used in different applications based on specific requirements.

- Q:Steels like YHB-2, MVS-8, and SK-5. Also if you know anything about these steels that would be helpful.

- White steel is a common shorthand name for white paper steel (shirogami hagane) which can be any of several fairly simple high carbon, water hardening steel grades. The carbon content varies by grade, and runs from 0.8 to 1.4%. The range of carbon content within a grade is a tight 0.1%. For example, the carbon content of Shirogami Hagani No1A is specified to be between 1.3 and 1.4%. Each grade also contains 0.1-0.2% silicon and 0.2-0.3% manganese, and only trace amounts of the impurities sulfur and phosphorus. Blue paper steel (aogami hagane) is also offered in several grades, with carbon content ranging similarly to the white grades. However, blue steel contains the additional alloying elements chromium and tungsten, and one grade (aogami super) also contains molybdenum and vanadium. The blue steels can be quenched in water or oil, whereas most of the white grades need a faster quench and require water.

- Q:What are the different types of steel coil cutting tools?

- In the market, one can find a variety of steel coil cutting tools. These tools have been specifically designed to efficiently and accurately cut steel coils. Some of the commonly used types of steel coil cutting tools include: 1. Slitting shears: These shears are widely utilized to cut steel coils into narrow strips. Equipped with multiple blades, slitting shears offer clean and precise cuts without causing any damage to the material. They are typically employed in high-volume production and are capable of handling different thicknesses of steel coils. 2. Rotary shears: Another commonly used cutting tool for steel coils is the rotary shear. These shears consist of rotating blades that shear through the material as it passes through them. Rotary shears are perfect for cutting medium to thick steel coils and are known for their high cutting speed and accuracy. 3. Guillotine shears: Guillotine shears are heavy-duty cutting tools that can handle thick steel coils. They operate by exerting a downward force to cut through the material in one clean stroke. Renowned for their power and precision, guillotine shears are suitable for cutting large volumes of steel coils. 4. Laser cutting machines: Advanced cutting tools like laser cutting machines employ a high-powered laser beam to cut through steel coils. These machines offer precise and intricate cuts with minimal heat distortion. Laser cutting machines are ideal for cutting complex shapes and patterns on steel coils. 5. Water jet cutting machines: Water jet cutting machines utilize a high-pressure stream of water mixed with abrasive particles to cut through steel coils. This method provides high accuracy and does not generate heat, making it suitable for cutting heat-sensitive materials. Water jet cutting machines can cut through various thicknesses of steel coils and produce smooth edges. Each type of steel coil cutting tool has its own advantages and is suitable for different applications. The choice of tool depends on factors such as the thickness of the steel coil, required precision, production volume, and budget.

- Q:looking to buy a sashimi knife. what is the difference between white steel (1and2) and blue steel (1and2) in terms on characteristics. what gets sharper? what holds edge longer? basically any info on the pros and cons of each steel would be SO GREATLY APPRECIATED! thanks in advance to all who answer. i'm leaning towards white-2 steel for my first sashimi knife, started training on the sushi bar and need a new tool!

- Blue Steel Knife

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Galvanized Steel Sheet Gi Coil for Building Materials

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords