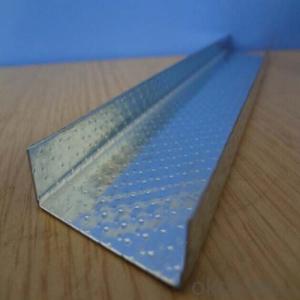

Galvanized Steel Profiles Drywall Stud

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 7000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

(1) Lightweight and high strength: 3-4 kg/m2 (1/10 of half brick wall), with yield strength 400mpa.

(2) Environment-friendly : galvanized steel-no radiation, have no harm to our health and not pollute the environment.

(3) Products with fillisters : Setting some fillisters in both sides of the keels in a selective way, in order to strength the keels' vertical points and intensity.

(4) The metal stud with hole : one of our product is the special hole on C-stud every 600mm, which is easy for workers to install the electric lines and water tubes.

(5) Various sizes of metal track and metal stud : we are able to manufacture German,

(6) Factory direct sale price : We have our own factory to produce raw materials----galvanized(zinc coated) steel, as well as the product line, so we can provide you a lowest price.

Specification

Galvanized Steel Specification

Pls kindly check our regular size as below,if you need other special size and thickness,pls contact us we will try our best to follow you or your engineer.

Item | Regular Size(mm) | |||

Thickness | Heught | Width | Length | |

Furring Channel | 0.4 | 22 | 35 | 3000.00 |

0.45 | ||||

0.5 | ||||

C Channel | 0.4,0.45,0.5 | 10 | 38 | 3000.00 |

0.45,0.5,1 | 12 | |||

L-Angle | 0.4,0.45,0.5 | 24 | 24 | 3000.00 |

25 | 25 | |||

Stud | 0.45,0.5,0.6 | 48 | 50 | 3000.00 |

48 | 75 | |||

32(34.5) | 73 | |||

Track | 0.45,0.5,0.6 | 40 | 50 | 3000.00 |

40 | 75 | |||

25 | 75 | |||

Advantages and features:

1. Galvanized Steel Profiles raw material is high quality hot dipped zinc galvanized steel strip, absolute damp proof , heat insulation and high durability , high rust resistance.

2. Hot dipped zinc galvanized steel strip zinc coating is 60-180g/m2.

3.Warm sales in Middle East , Africa ,

4. The specification can follow up customer requirements.

5. Advanced equipment can make sure exactly size, high quality products.

6.High quality cold rolled continuous hot galvanized plate as raw materials which makes sure it is anti-corrupt and anti-rusty

7.drywall steel profile adopts excellent manufacture equipment,advanced production process, scientific and detecting method.

8. Steel profile has beautiful surface, medium hardness! Good quality *competitive price large quantity *honesty *good after-service

Certificates ISO 9001:2000 Quality management system

FAQ

1.Sample: small sample can be offered by free

2.OEM: OEM is accepted

3.MOQ: small order is ok

4.Test: any third party is accepted to test

5.Factory: Can visit factory any time

6.Delivery Time: small order is within 7days or according to your order

- Q:Who used the light steel keel gypsum board to do the wall?

- The sound insulation effect than the brick or a little worse but have their own advantages and disadvantages of the small space that is also cheaper than the brick wall is suitable for wardrobe compartment

- Q:Light steel keel wall and wood which low cost

- Do with the wall, then, certainly with light steel keel production is better. As for the cost, can be used to do the wall of the board, it should be relatively thick, so that its price will be more than the price of gypsum board, and then the cost of light steel keel equivalent.

- Q:Light steel keel wall can be installed sliding door

- How can not press ah. It is estimated that you are afraid of wood that you fooled you And your door is too big to shrink it. The normal door is 800. Get so much useless. Now the light steel keel wall is too much. How can we press the door.

- Q:Light steel keel gypsum board wall height is how to determine

- There is no specific rigid provisions, the specific height according to the actual situation to the scene. Light steel wall commonly used for each root is 3 meters long, if the actual height beyond too much, you can order.

- Q:Light steel keel wall how much money a square

- Steel keel wall with light weight, high strength, good fire resistance, versatility and easy installation characteristics, to adapt to shock, dust, noise, sound absorption, constant temperature and other effects, but also has a short duration, construction is simple Deformation and other advantages.

- Q:PVC plastic buckle the corners of the corner is how fixed to the wall of the buckle is how and cords connected to the light steel keel and gypsum do cut off the light steel keel is how and the wall surface and ceiling how fixed

- Each corners above the U-slot, this is the use of the buckle board. Light steel keel sub-station dragon and Wolong. Wolong before the installation of the first hammer with a hammer, playing wooden needle, and Wolong fixed, and then install the station dragon, and clamp with a good fit.

- Q:Has installed a wooden floor, you can do in the above light steel keel wall?

- Can, to the dragon it to use a little bit of the screw, but look at your floor is still in the cement or above the floor to do in the cement above with a drill to pull the explosion can be a With a long screw, If it is done on the floor of the board it, It is recommended to use a little bit of the screw to play on the above plus gasket To do about the foot line, and the floor color, only to coordinate points

- Q:Light steel keel gypsum board partition should pay attention to what quality problems

- Bathroom, bath and other multi-water room and high humidity room light steel keel gypsum board wall of the root, the application of C15 concrete to do 120mm high wall base. Gypsum board seams should be used by the manufacturers supporting the supply, dedicated to the joints with the caulking paste and cap joints to ensure that the quality of gypsum board joints.

- Q:Wood keel can be used to ceiling, can be used to do the wall? Light steel keel can be used in what place?

- Many temporary buildings will use wood keel to do with the wall, light steel keel more for long-term construction

- Q:How to do woodworking partition wall, with door

- Wood keel construction procedures: clean up the grass-roots level → line, looking for rules → in the ground with brick, cement mortar to do pillow belt (also known as kicker) → elastic line, back to the ceiling and the main structure of the wall → Vertical frame wall → installation along the ground, along the top of the flute → stand off the keel → nail cross keel → cover panel, set the socket location and set up to strengthen the pad wood panel cover.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Galvanized Steel Profiles Drywall Stud

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 7000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords