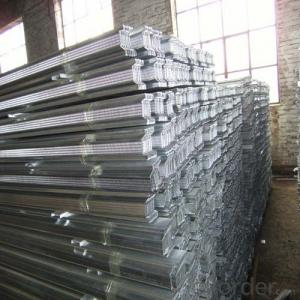

Galvanized Steel Material Furring Channel For Drywall Ceiling Grid

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 300000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Specification for middle east:

Main Channel | 38x12 mm |

Furring Channel | 68x35x22 mm |

Wall angle | 25x25 mm |

C stud | 50x35 mm |

C Stud | 70x35 mm |

C stud | 75x35 mm |

U track | 52x25 mm |

U track | 72x25 mm |

U track | 75x25 mm |

Specification to Australia:

top cross rail | 25x21x0.75 mm |

25x21x0.75 mm | |

Furring Channel | 28x38x0.55 mm |

16x38x0.55 mm | |

Furring Channel track | 28x20x30x0.55 mm |

16x20x30x0.55 mm | |

Stud | 64x33.5x35.5 mm |

76x33.5x35.5x0.55 mm | |

Stud | 92x33.5x35.5x0.55 mm |

150x33.5x35.5x0.55 mm | |

Track | 51x32x32, 64x32x32x0.55 mm |

76x32x32x0.55 mm | |

Track | 92x32x32x0.55 mm |

Specification to Europe, Russia, UKrain, Georgia. etc

C Stud | 60x27 mm |

U track | 28x27 mm |

C stud | 50x50 mm |

C stud | 75x50 mm |

C stud | 100x50 mm |

U track | 50x40mm |

U track | 75x40 mm |

U track | 100x40 mm |

Drywall section metal profile

1. Usage: gypsum board drywall

2.Easy to install

3.High strength

4.Size exact, easy cut

Metal steel profile stud and track light steel keel for drywall system

Product Overviews

Product characteristic

1) High quality of raw material with hot dipped Galvanized steel coil

2) Easy to operate and solid after installation

3) Durable for at least 10 years life-span

4) Moisture proof, Rust resistance

5) Many difference size. Export to different market

FAQ

1.Sample: small sample can be offered by free

2.OEM: OEM is accepted

3.MOQ: small order is ok

4.Test: any third party is accepted to test

5.Factory: Can visit factory any time

6.Delivery Time: small order is within 7days or according to your order

- Q:Home to do light steel keel partition sound insulation, dare not use glass wool, with sponge or benzene as a filler for what kind of noise, good environmental protection

- Benzene board and extruded board can be, are more suitable for home improvement. I do with the noise is extruded board than the benzene board sound insulation is also very good environmental protection

- Q:9 + 9 double gypsum board is what it means

- Gypsum board is a kind of material made of building gypsum as the main raw material. It is a light weight, high strength, thinner thickness, easy processing and insulation and fire insulation and other properties of better building materials, is currently focused on the development of one of the new lightweight sheet. Gypsum board has been widely used in residential, office buildings, shops, hotels and industrial plants and other buildings within the wall, wall panels (instead of wall plaster layer), ceilings, sound-absorbing panels, ground floor boards and the Such as decorative plates. Gypsum board gypsum board (divided into ordinary gypsum board (commonly used), fiber gypsum board, gypsum decorative plate "interpretation") it to gypsum as the main material, adding fiber, adhesive, modifier, Dry from. With fire, noise, heat, light, high strength, low shrinkage and other characteristics and good stability, not aging, anti-moth, available nails, saws, planing, sticky and other methods of construction.

- Q:Light steel keel partitions and finished partitions

- Light steel keel partition is one of the most common decoration projects in the field of decoration and decoration. It is made of light steel keel as the basic skeleton, the surface gypsum board is made of wall layer and fixed to the top and top of the building. Wall; it needs to use talcum powder, such as putty layer, latex paint or wallpaper as a surface decoration, are produced on-site.

- Q:6 meters high ceiling to do 4 meters with light steel keel do wall light steel dragon skeleton is to do 6 meters to the top or do high

- How high the ceiling, light steel structure of the wall, can be fixed, it does not matter how high. To the top of the ceiling above a dozen centimeters on it

- Q:What is the difference between gypsum board partitions and lightweight partitions?

- Functional distinction, light partition is mainly used to replace the brick and the larger compartment, play a fire insulation and insulation and other effects, and gypsum board partition, mainly the role of partition, thermal insulation effect Relatively poor, so between the two plates to be filled, such as rock wool, sound insulation cotton and so on. In short the two products are different, to see where, to achieve the main effect is what.

- Q:Can the interior walls be made of light steel keel partitions? Bathroom wall and interior wall with light steel keel wall is good or brick wall good?

- Light steel keel (generally with gypsum board) wall lightweight, easy construction, low cost, a large number of indoor partitions,

- Q:Waterproof gypsum board for toilet partition and paste tile installation steps?

- Waterproof gypsum board called calcium silicate board; more common brands are Edite board, silver special board, gold palace board 1, the use of U75 thick (or national standard) wall light steel keel; heaven and earth keel and vertical keel are using the same model and thickness. U38 type through the keel can be used to strengthen. Vertical keel center spacing of 400MM; use of special light steel keel calipers connected fixed. 2, the use of double-sided double-sided panel technology construction, must be the same layer of different layers of wrong stitching; that is, the bathroom wall keel positive and negative were closed a layer of waterproof gypsum board. With special Tektronix special 4 * 20 anti-rust self-tapping screws. Screw spacing of not more than 20CM.

- Q:Light steel keel partition wall fire retardant coating shabu several surface

- Grass-roots side of the wooden side need to brush four sides, the base liner is two sides, but the paste surface layer of decorative panels generally just brush a back, the front is usually not brush fire paint, or should be the quality of surface layer decorative plate paste.

- Q:Light steel keel gypsum board partition should pay attention to what quality problems

- For the wall (or the top wall of the building), the distance between the vertical keel shall not be greater than 400mm, the distance between the transverse keel shall not be more than 600mm, and the fire gypsum board shall be used. Fixed, the upper edge of the gypsum board fixed on the top with the keel, the board from the floor should be greater than 20mm, and fire sealant with solid.

- Q:How to remove the gypsum board cut off

- Partition may be a metal structure, can not be sparks in the environment, can not use cutting machine, can not use metal hit metal. Can not use the fire.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Galvanized Steel Material Furring Channel For Drywall Ceiling Grid

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 300000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords