Galvanized Steel Cuplock Scaffolding System For Heavy Construction CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details of Galvanized Steel Cuplock Scaffolding System For Heavy Construction

Name Cuplock Scaffold System Size Many sizes or as your request Main Material Q235/345 Steel Surface Treatment High Protected Painted, Powder Coating, Electric Gavenized, Hot Dip Gavenized. Color Silver, Orange, Red Certificate SGS, EN12810. Service OEM Service available MOQ 50T Payment T/T, Western Union Delivery Time 15-25 days after deposite Packing in bulk or steel pallet or as your request production capability 50 tons per day Main Market Africa, South America, the Middle East and Asia

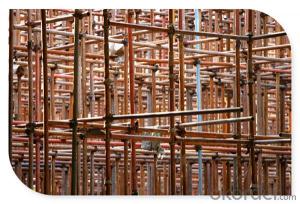

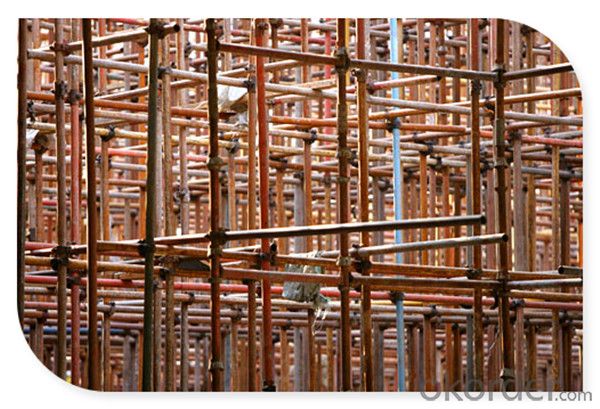

Descriptions of Galvanized Steel Cuplock Scaffolding System For Heavy Construction

Cuplock is a kind of multi-purpose and versatile modular system scaffolding, suitable for access and formwork support in all types of construction of building & civil engineering projects, offshore projects, etc. This complete galvanized Cuplock system is probably the fastest and most widely preferred scaffolding system. It has flexible erection as straight, curved or circular configuration for both access and support purposes.

Futures of Galvanized Steel Cuplock Scaffolding System For Heavy Construction

1.Cuplock scaffold system is simple in structure,including top cup,bottom cup and ledger blade.

2.Quick installation of horizontals and verticals,you can easily fit the ledger blade into the cups with a hammer.

3.Cuplock scaffold system standards are made from higher quality steel tube which allow more than 58KN load per leg.

4.Cuplock scaffold system is a multi-functional scaffolding system which is suitable for all forms of access and support structures,especially used in bridege building.

5.People can fasten joint of ledgers by putting two extra ledger blades in the cups.

6.This cuplock scaffold system are interlocked by cups and ledgers which is very safe and stable steel scaffolding system.

7.This is a heavy duty scaffold system which can load about 16tons for each cuplock scaffolding system.

8.Cuplock scaffold system can be used both interior or outerior high-rise building construction project, expecially for arc shape building such as bridge, tunnel, subway, or gym building. it's multifunctional.

9.This is a galvanized cuplock scaffold system which surface is hot dip galvanized, it can keep a longer working life.

10.Gavanized cuplock scaffold system is water-proof scaffold sysem which can prevent the air and water to damage the cups and ledgers very effectively.

11.Cuplock scaffold system can be quick to errect by interting the cuplock blade into bottom cup, then swivel the top cup to fixed it.

12.Suitable for transportation and storage: Single cuplock scaffold system standard and ledger occupy less space. Wiht no extra parts.

The Measures of Galvanized Steel Cuplock Scaffolding System For Heavy Construction

Standard: 3000mm, 2500mm, 2000mm, 1500mm, 1000mm, 500mm.

Ledger: 3000mm, 2000mm, 1780mm, 1500mm, 1000mm, 500mm.

Diagonal brace: 3000X2000mm, 1780X2000mm, 1000X1500mm, 1000X2000mm, 1500X2000mm,

Tube specification: Φ 48.3X4.0mm, φ 48.0 X3.25mm, φ 48.0 X3.0mmFAQ

1. What is considerations of Scaffolding installation?

There must be a fire protection measures and specialist care, safety personnel patrol inspection when electricity, gas welding work on the scaffold,

(1) scaffold frontage hurtful to prevent falling objects protection is required.

(2) During take down the scaffolding, fencing and warning signs should be set up on the ground, prohibit others person besides the operator

2.What are the certifications of your products?

Certified by SGS, BS1139, EN74, Local Test Report.

3. How long is the warranty period for your product?

Our products warranty is 2 years.

- Q:Bowl buckle scaffold inspection and evaluation

- Bowl buckle scaffold should be checked and accepted as follows:(1) access to the site of the bowl buckle frame fittings shall have the following information:

- Q:What is the service life of the mobile scaffolding accessories?

- Hot galvanized mobile scaffolding accessories for a period of 10 years or so, the surface does not require maintenance, in use without any restrictions. However, the cost is high, the raw materials needed to be more complex.

- Q:Who has external scaffolding construction program

- 1.1.2 fastener1 steel tubular scaffold made of malleable iron fasteners, the material should be consistent with current national standard "steel pipe scaffolding fasteners" (GB15831) regulations; the fastener made by other materials used, test show that the quality meets the standard requirements before use.2 fastener used in the scaffold, bolt tightening torque up to 6.5N.M, shall not be damaged.1.1.3 foot plateThe scaffold made of bamboo or bamboo bamboo string plate, each quality should not be greater than 30kg.1.1.4 wall partsThe material of the wall parts shall be in accordance with the provisions of the current national standard "Q235-A" (GB/T700).1.2 inspection of qualified parts should be classified according to the varieties, specifications, stacked neatly, smooth, stacking sites may not have water.1.3 should be cleared to set up the site debris, flat set up the site, and make water flow.1.4 when the foundation of the scaffold has equipment foundation, pipe trench, the scaffolding should not be used in the process of excavation, otherwise it is necessary to take reinforcement measures.

- Q:What are the components of a mobile scaffolding

- The utility model relates to a standard steel pipe scaffold which is connected with the main structure of the wall and is connected with the main structure of the building.

- Q:Scaffolding scaffolding erection norms which requirements, who can say?

- The construction load on the frame must be in accordance with the design requirementsAfter the first erection of the body, must be approved by the company's safety and technical departments, and the company's project safety officer after the visa can continueIn case of suspension frame, use more than one month, such as re started, the frame must pass the reinforcement, rod must be re tighten oil, can be usedBefore the building should be approved with the consent of the special construction plan, should be in accordance with the scheme requirements of embedded embedded parts of the main structure of the construction processFeet should be laid flat tile, and tied with wire fixed on the lower supporting steel pipe. Scaffold of the butt joint between the tile, the rest of the bearing rail spacing shall not be greater than 400~700 mm

- Q:I really want to get one done and I would like it if someone could tell me how badly does it really hurt? During and after. I know everybody has different pain thresholds but on average? I'm just nervous to get it done but really want another piercing on my ears. I have my lobes and a cartilage on my right ear. How easy is it to clean? rate in numbers as well as a description. Thanks.

- When I got my industrial, it hurt more after wards. During the first week, it was a pain to sleep. Just make sure you clean it twice a day so it doesn't get infected.

- Q:what are the scaffolding building on I-44 between milemarker 282 and 283 east bound on the north side of the h

- Are you talking about where the trains are? The cylander shaped buildings? They are oil/fuel tanks... they have a big balloon like thing with a weight on top that as it fills will fill out inside the scaffolding. I have not seen them filled in years though.

- Q:Im 18 years old and maleI have 4 piercings. On my left I have my lobe and a double helix (a type of cartilage piercing). On my right I have a scaffold/industrial. I know I want another piercing on my right ear, but cant decide what to get. Any input is greatly appreciated.

- conch would look great and not make it look to cluttered go for it :)

- Q:What are the characteristics of Pankou scaffolding

- Pankou scaffolding, unique technology of hot dip galvanizing, hot-dip galvanizing is a strong adhesion, used for a long time, a uniform film coating.

- Q:I know people have different pain thresholds. But I was wondering if it was more painful than a lobe piercing? It will be done with a needle and are they aloud to freeze it? Or is it not needed?

- Scaffold/Industrial piercings definately hurt more than a regular lobe piercings because it's in the cartilage area and its pierced at a larger gauge but the pain is bareable. On a scale of 1 to 10 (10 being the worst pain) I would say an Industrial would be anywhere from a 4-6 depending on your pain threshold. Freezing it probably wouldn't be nessesssary. I got a 14g Industrial pierced on one ear and a 16g helix on the other both on the same day (the industrial was done first) and in my opinion the 16g helix hurt more. So it really depends on how well you tolerate pain

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Galvanized Steel Cuplock Scaffolding System For Heavy Construction CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords