Galvanized Steel Coil with Best Quality in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot-dip Zinc Coating Steel Building Roof Walls

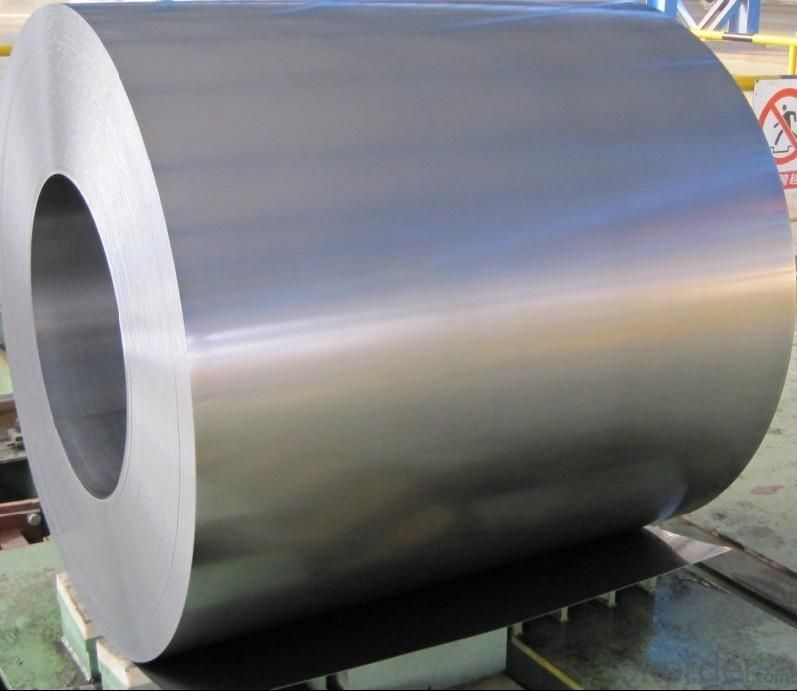

1.Structure of Hot-Dip Galvanized Steel Sheet Description:

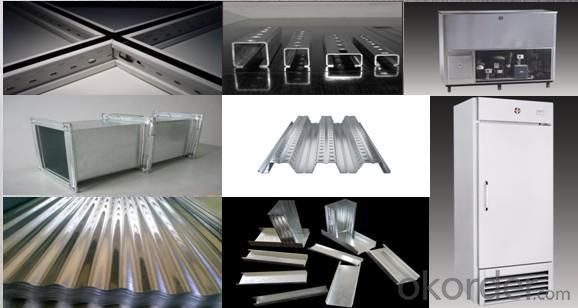

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial applications. Production of cold formed corrugated sheets and profiles for roofing, cladding, decking, tiles, sandwich walls, rainwater protective systems, air conditioning duct as well as electrical appliances and engineering.

2.Main Features of the Hot-Dip Galvanized Steel Sheet:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent anticorrosive property

• High strength

• Good formability

• Good visual effect

3.Hot-Dip Galvanized Steel Sheet Images:

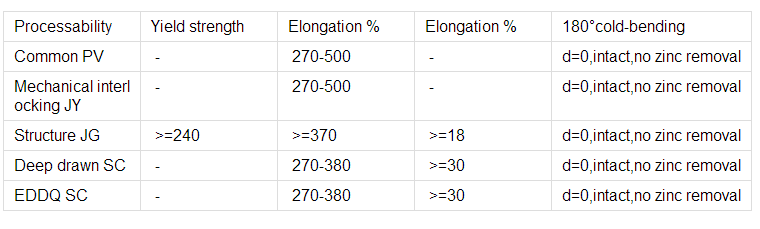

4.Hot-Dip Galvanized Steel Sheet Specification:

Standard: ASTM, JIS,EN

Grade: CS, DX51D+Z,SGCC, SS 230~550,S220GD+Z~S550GD+Z, SGC340~SGC570

Thickness: 0.1mm~5mm

Width: max 2000mm

Coil weight:3-12 MT

Coil ID:508/610mm

Surface structure: zero spangle, regular spangle or minimum spangle

Surface treatment: Chromate treatment, Oiled/dry, skinpassed/non-skinpassed

Packing: Standard seaworthy export package

Technology test results:

5.FAQ of Hot-Dip Galvanized Steel Sheet:

We have organized several common questions for our clients,may help you sincerely:

1.How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

2.How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-30 days, but the shipment will depend on the vessel situation.

- Q:What are the different types of steel coil loading and unloading devices?

- There are several types of steel coil loading and unloading devices, including coil carriages, coil lifters, coil turners, coil grabs, and coil tilters. These devices are designed to safely and efficiently handle steel coils during the loading and unloading process, ensuring smooth operations in various industries such as manufacturing, construction, and transportation.

- Q:I have a new stainless steel trash compactor under a butcher block counter. We refinished the countertop, but unfortunately the person who did it wasn't careful with the orbital sander and sanded the top edge of the stainless steel compactor door, ruining the finish. The sander marks are not deep - just surface scratches - but they are unsightly. Is there any way to restore the finish to the stainless steel without having to buy a new door?

- Go over the entire surface with wet/dry sandpaper with the grain. Use wet with a little dish detergent. Remove the handles and name plates first. Start with 400, then 600, and then 800. Auto supply should sell the sandpaper. After final sanding, wax with carnuba wax and polish. Works on aluminum and real stainless not painted surfaces.

- Q:How are steel coils used in the manufacturing of electrical enclosures?

- Steel coils are used in the manufacturing of electrical enclosures as they can be formed into various shapes and sizes to create the enclosure's structure. The coils are typically cut, bent, and welded together to form the walls, base, and lid of the enclosure, providing a sturdy and protective housing for electrical components.

- Q:What are the different types of steel coil treatments?

- There are several types of steel coil treatments, including pickling, oiling, and galvanizing. Pickling involves immersing the steel coil in an acid bath to remove impurities and scale, resulting in a clean surface. Oiling is the process of applying a thin film of oil to the coil to prevent corrosion during storage and transportation. Galvanizing is a treatment where a layer of zinc is applied to the steel coil, providing excellent protection against corrosion.

- Q:Can steel coils be coated with zinc-aluminum alloy?

- Yes, steel coils can be coated with zinc-aluminum alloy.

- Q:A song by brokencyde is called Blue Steel.... a verse in it says Don't make me show you blue steel.

- Blue okorder /

- Q:I am making a permanent magnet, just for fun. I am trying to find the best grade of steel to do so with.

- The type of steel you require is Steel ( Iron + Carbon, mainly.),{many different types of steel } with a high Cobalt and Nickel content. These alloyed together give the best Permanent Magnets, mainly due to their own individual magnetic properties / characteristics being retained in the Alloy. All 3 metals can be magnetised by there own, but Cobalt is known to cause cancer. Nickel, is poisonous and can also cause sever Dermatitis and the destruction of skin tissue.But when alloyed together with Iron they are pretty harmless. Interesting thing is, All of these metals (in this case Elements) can share the same Mass Number ( 60 ). And yet are totally different in their other properties beside Magnetism. Cobalt - Samarium - alloys, create some of the worlds most powerful permanent magnets. And were used in medicine, But are now superseded by Neodymium magnets which are employed instead. Edit; What you could try is, mild steel which is widely available and easily found. . The steels mentioned above are pretty exclusive materials and I personally would not know how to test for their contents, of which they are made from. Soft Iron is good for making electro-magnets if you fancy a go at making one. .

- Q:How do steel coils contribute to energy savings in buildings?

- Steel coils contribute to energy savings in buildings by being used in various applications that help improve insulation and reduce heat transfer. They are commonly used in HVAC systems, where they act as heat exchangers, transferring heat between air streams. Steel coils with high thermal conductivity ensure efficient heat transfer, allowing for effective cooling or heating of air without excessive energy consumption. Additionally, steel coils are utilized in the construction of insulated walls and roofs, forming an integral part of the building envelope. This helps minimize thermal bridging, preventing heat loss or gain through the building's structure. By improving insulation and reducing energy transfer, steel coils play a crucial role in enhancing the overall energy efficiency of buildings, leading to significant energy savings.

- Q:Eutectoid Steel

- Eutectic steel is used to produce pearlite, bainite, spheroidite and martensite steels. Those steels vary in strength, hardness and ductility. One uses martensite steel for example in razor blade manufacturing. Of course there is no end to the various uses of these steels.

- Q:What are the common sizes of steel coils?

- The common sizes of steel coils vary depending on the specific application and industry. However, some standard sizes for steel coils include widths ranging from 0.5 inches to 72 inches, and thicknesses ranging from 0.010 inches to 0.250 inches. These sizes can be customized to meet the specific requirements of different industries such as automotive, construction, or manufacturing.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Galvanized Steel Coil with Best Quality in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords