Galvanized Steel Coil/Sheet in Best Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot-dip Zinc Coating Steel Building Roof Walls

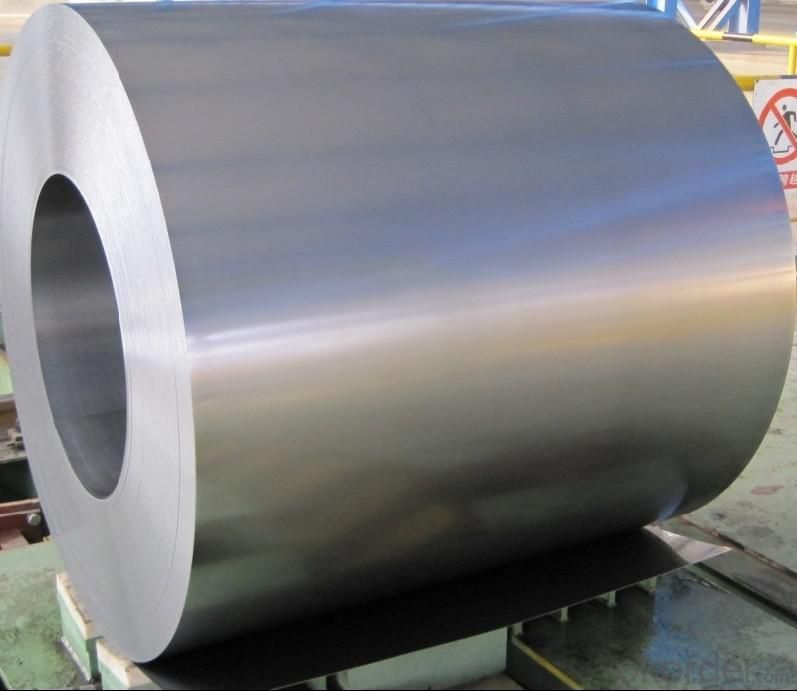

1.Structure of Hot-Dip Galvanized Steel Sheet Description:

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial applications. Production of cold formed corrugated sheets and profiles for roofing, cladding, decking, tiles, sandwich walls, rainwater protective systems, air conditioning duct as well as electrical appliances and engineering.

2.Main Features of the Hot-Dip Galvanized Steel Sheet:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent anticorrosive property

• High strength

• Good formability

• Good visual effect

3.Hot-Dip Galvanized Steel Sheet Images

4.Hot-Dip Galvanized Steel Sheet Specification

Standard: ASTM, JIS,EN

Grade: CS, DX51D+Z,SGCC, SS 230~550,S220GD+Z~S550GD+Z, SGC340~SGC570

Thickness: 0.1mm~5mm

Width: max 2000mm

Coil weight:3-12 MT

Coil ID:508/610mm

Surface structure: zero spangle, regular spangle or minimum spangle

Surface treatment: Chromate treatment, Oiled/dry, skinpassed/non-skinpassed

Packing: Standard seaworthy export package

Technology test results:

| Processability | Yield strength | Elongation % | Elongation % | 180°cold-bending |

| Common PV | - | 270-500 | - | d=0,intact,no zinc removal |

| Mechanical interlocking JY | - | 270-500 | - | d=0,intact,no zinc removal |

| Structure JG | >=240 | >=370 | >=18 | d=0,intact,no zinc removal |

| Deep drawn SC | - | 270-380 | >=30 | d=0,intact,no zinc removal |

| EDDQ SC | - | 270-380 | >=30 | d=0,intact,no zinc removal |

5.FAQ of Hot-Dip Galvanized Steel Sheet

We have organized several common questions for our clients,may help you sincerely:

1.How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

2.How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-30 days, but the shipment will depend on the vessel situation.

- Q:How are steel coils labeled and identified?

- Steel coils are labeled and identified through a variety of methods to ensure proper tracking and handling throughout their journey. The labeling and identification process typically involves the following steps: 1. Manufacturer's Identification: The steel coil is initially marked with the manufacturer's name or logo, allowing for easy identification of the company that produced it. 2. Coil Number: Each steel coil is assigned a unique identification number, commonly referred to as a coil number. This number is often stamped or etched onto the surface of the coil and is used for tracking and inventory purposes. 3. Size and Weight: Steel coils are labeled with their size and weight specifications. This information helps in determining the dimensions and weight capacity of the coil, allowing for appropriate handling and transportation arrangements. 4. Grade and Material: The grade and material composition of the steel coil are typically indicated on the labeling. This provides essential information about the properties and quality of the steel, ensuring it is utilized correctly in manufacturing processes. 5. Heat or Lot Number: Steel coils can also be labeled with a heat or lot number, which refers to the production batch from which the coil originated. This information helps in traceability and quality control, facilitating identification in case of any issues or defects. 6. Barcodes or QR codes: Many steel coils are now labeled with barcodes or QR codes, which can be scanned using automated systems. These codes contain all relevant information about the coil, allowing for efficient data capture and management throughout the supply chain. Proper labeling and identification of steel coils are crucial for effective logistics management, inventory control, and quality assurance. By employing these identification methods, manufacturers, distributors, and end-users can easily track, handle, and utilize steel coils in a safe and efficient manner.

- Q:What is the diffrent Aluminized steel Type 1. stainless steel 409 430?

- Alloy steel is a stainless steel. The differences between the two are the composition of the metal. Alloy steel is steel with usually less than 5% of other elements, like molybdenum, copper, chrome while stainless steel is a steel with at least 10-11% of chromium.

- Q:can anyone tell me the way to bring back the shine to the stainless steel kitchen sink . It has become dull.

- Lowe's has a stainless steel cleaner/polish....it works great!!

- Q:what do they use to make stainless steel?and can stainless steel be melted again and again without losing it's Specifications

- The basic ingredient is from 11%-30% chromium, however in many stainless steels nickel or manganese are important secondary ingredients. There are two basic types of stainless steels: 1)austenitic stainless steels, and 2)ferritic stainless steels. In austenitic SS the important ingredients are Chromium and Nickel. (Chromium and manganese are occasionally use instead of nickel.) It's important to note that many austenitic SS's contain almost no carbon, so by some definitions they are not steel at all but iron/chromium/nickel alloys. the additions of nickel (or manganese) actually changes the crystal structure of the iron, so the properties of these types are quite different from normal carbon steels. Austenitic SS have very good to excellent corrosion resistance, and fairly good heat resistance. In ferritic stainless steels, the important ingredients are chromium and carbon. Ferritic stainless steels have markedly greater strength than austentitic types. However since they contain less chromium than austenitic types they are only moderately corrosion resistant and are much less heat resistant. Without the addition of nickel and/or manganeese adding more than about 20% chromium tends to make the steel brittle. Most stainless steel is melted under an inert argon atmosphere in an airtight furnace. Melting stainless in open air would preferentially oxidize the chromium, forming slag which would float to the surface of the steel, thus reducing the chromium content. Chromium also tends to react with nitrogen in the air at high temperatures, exposure to nitrogen tends to cause brittleness in stainless steels. As long as the manufacturer keeps careful control of the composition of the metal and the level of impurities during melting, stainless is endlessly recyclable.

- Q:What are the factors affecting the price of steel coils?

- There are several factors that can affect the price of steel coils. Some of the key factors include the demand and supply dynamics of the steel market, global economic conditions, raw material costs, production costs, government policies and regulations, currency fluctuations, and competition among steel manufacturers. Additionally, factors like transportation costs and energy prices can also impact steel coil prices.

- Q:Iron melts faster when there will be low carbon in Iron.During steel making the molten Iron gets purified and alloying being done through the process. How the carbon is being controlled at Iron melting stage and what it is called?

- Steel is usually made in a two-step process. As you may know, carbon, in the form of coke, is added to the iron ore during the initial smelting process. This is the first step. The conversion of iron ore into raw iron is accomplished with a blast furnace. Carbon dissolves with the iron during the smelting process. The amount of carbon in the iron is generally not controlled at this point as this would be too difficult, the excess carbon is removed in the next step. The result is pig iron which is crude iron that has a very high carbon content, and a large amount of impurities. Pig iron is almost as brittle as glass, and it is useless in this form. In most modern steelmaking operations, molten pig iron is tapped from the blast furnace three or four times per day- it is not allowed to cool. The liquid pig iron is carried in ladles directly to a Basic Oxygen Furnace which converts the pig iron into steel. The basic oxygen converter uses a stream of pure oxygen to burn off the excess carbon. Impurities are also burned off, particularly phosphorus, silicon, and sulfur (which damage the steel's properties.) These elements all have a much higher affinity for oxygen than iron does, so the iron itself remains unchanged. Once the carbon content and the impurities are reduced to the desired level. The oxygen is shut off, and the iron has now become steel. At this point other alloying elements may be added, such as chromium, manganese, or molybdenum. These elements improve the steel's properties, but also add to it's price. If necessary, more carbon can be added as well if the carbon content has accidentally dropped too low. Finally, molten steel from the basic oxygen furnace is poured off. It can be cast into ingots, billets, or thin slabs.

- Q:Are Danielle steel books good to read. Im 15 , but do I have to wait until Im a bit older.

- Wait until you are eighty, the dementia will make the process less painful Otherwise, you know best how mature you are and Danielle Steel is sugary romance, not really sex.

- Q:How do steel coils contribute to the oil and gas industry?

- Steel coils are an essential component in the oil and gas industry as they are used to manufacture various equipment and structures like pipelines, storage tanks, and drilling rigs. These coils provide the necessary strength, durability, and resistance to corrosion required for the harsh operating conditions in the industry. Additionally, steel coils are crucial in the transportation of oil and gas as they are used in the construction of tankers and pipelines, ensuring the safe and efficient movement of these valuable resources.

- Q:Are steel coils affected by temperature changes?

- Yes, steel coils are affected by temperature changes. Steel is a metallic material that expands when heated and contracts when cooled. Temperature fluctuations can cause steel coils to expand or contract, which may impact their dimensions, mechanical properties, and overall performance. It is important to consider and manage temperature changes to ensure the proper functioning and durability of steel coils.

- Q:Who started or popularized the use of the steel guitar in country music? Early country songs contained no steel guitars but by 1950 the steel guitar had become a staple of country music.

- You're an idiot. Only an ignorant fool would attempt to generalize an entire genre into one unappealing stereotype, rather than putting forth the effort to actually LISTEN to the music. 'Horrible Instrumentals?' Really? Some of the best guitar players on the planet are country singers (ever heard of Brad Paisley? Keith Urban? Chet ADKINS, for gods sake, who, in his prime, was one of the best guitarists on the planet?) 'Terrible Vocals'? You're joking, right? I know you're joking. You HAVE to be joking, considering the amount of 'talent' most popular pop artists at the moment have. Ever heard Katy Perry sing Live? Rihanna? Britney Spears? Miley Cyrus? Fergie? Selena Gomez? Ke$ha? And these are the most dominant pop singers in the world right now. And you think its your place to be criticizing country musician's vocals? Country music is KNOWN for having phenomenally talented singers, both in and out of the studio. (Carrie Underwood, Brad Paisley, Faith Hill, Tim McGraw, Toby Keith, Lady Antebellum, Reba McEntire, Rascall Flatts and many, many more) Mediocre Topics? Love, Heartbreak, Family, Patriotism, Sex (occasionally). The same general topics that EVERY genre explores. How would you like it if i said that all rappers sing about is f*cking b*tches and driving fancy cars? Yeah, I'm guessing you'd think that sounded pretty ignorant. Dull Lyrics? Country music is known for being the kind of music that tells a story throughout the song, not just repeating the same few catchy verses and a chorus like other genres. If you find that kind of story telling boring, then go listen to some Katy Perry. She sounds like she's more your style.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Galvanized Steel Coil/Sheet in Best Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords