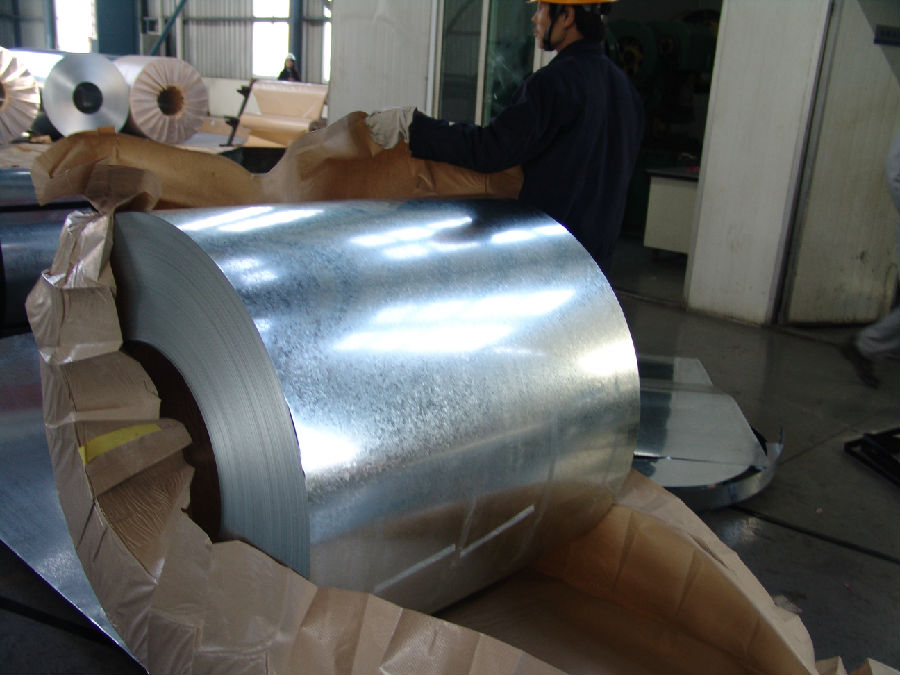

Galvanized Steel Coil-JIS G 3302 SGCC-0.5mm*1000mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Galvanized steel coils are widely used in the construction industry, as raw material for the production of corrugated panels, fencing products, drywall panel profiles, ventilation systems etc. Recommended for both outside and inside usage, galvanized steel has a high resistance to corrosion in different environments, due to a protective layer of zinc of 100 – 180 grams per square metre.

Hotdip galvanized steel coils are produced by immersing steel in a zinc bath. An appropriate galvanizing process requires a pretreatment process during which the steel passes through different baths which prepare the surface for zinc coating. In this stage, chemicals are used to clean the surface of the steel. After the chemical treatment, the steel coils pass through a bath of melted zinc at temperatures around 460 ° C.

The resulting uniform coating is finished through a process of skinpassing to provide smooth and shiny appearance of the finished product.To store for a longer period, the hotdip galvanized coils can be delivered with a final oil coating, according to the customer’s demand. PROFILAND STEEL produces hotdip galvanized steel coils with very good workability at further cold forming and bending processes.

- Q:How are steel coils used in the manufacturing of solar panels?

- Steel coils are used in the manufacturing of solar panels primarily for the structural support and durability they provide. These coils are often used to construct the frames and mounting systems that hold the solar panels in place. The strength of steel ensures that the panels remain stable and secure, even in harsh weather conditions. Additionally, steel coils can be shaped and formed to meet the specific design requirements of solar panel installations, making them a crucial component in the manufacturing process.

- Q:hey... i don't need to change my strings, but i found a set of Bronze acoustic guitar strings by pure tone... i have a few questions on them:can i put them on a steel string guitar? i know i can't put nylon strings on... but i don't see why i can't put bronzethey are light gauze... i have no idea what my current gauze is, but i play in Dropped D tuning... so would the E/D string (6th) be too loose? finally, can you get strings designed to be played in Drop D?any help is apprechiated :D

- Are you talking about a steel guitar or a steel string guitar. Bronze strings won't work properly on a steel/lap steel/electric guitar but hey are designed to be played on an acoustic or acoustic electric steel string guitar. Light gauge strings are OK. However, the low E may be too thin if you tune that down to D. Another thing to consider is that the neck truss rod probably needs to be adjusted slightly if you change string gauge. This procedure is fast and simple if you know what you're doing. You should however leave it to someone else if you don't know how it's done. If you play all the time in drop D, I would probably use a set of medium strings or have a light set and use a heavier low E-string. Personally, I use drop D on my acoustics from time to time. I use light strings and find this to work well for me.

- Q:I'm pretty sure that this topic has been beaten to death by now. But, I still can't get a definite answer. With stainless steel, you get better corrosion resistance, and you will hold and edge longer. With carbon steel, you will hold a sharper edge, and you could forge a knife blade longer than 2 ft without breakage. I'm personally a fan of stainless steel ( the 440 grade stuff ), just because it seems to hold up to use and abuse better in the long run. HOWEVER, I have NEVER had a factory made knife break on me. I don't think that they would try to sell you a knife that didn't do what it was meant to do, at least to a reasonable degree. (I work for a living, and can't afford a custom $600 knife.) What do you think? Is this a pointless topic? Will there ever be a winner?

- If your talking about a folding pocket knife, I think that it's basically six one way and a half dozen the other. I actually do prefer stainless for my pocket knives. I don't want to oil a knife to the degree I feel carbon requires, only to then stick it my pocket to attract dirt to the knife and oil to my pants. I'm the exact opposite on sheath knives though. I like 1095 carbon steel, plain edge sheath knives. I'll thrash on them HARD, and I rarely have major edge problems. Of course, I require them to be coated with some kind of powder coat or the like, because they can rust, but I do try and keep them clean and dry when in the sheath, so they won't pit the uncoated edge. My reasons for this sheath knife preference is multi-fold. First, these knives are simply affordable. I don't spend $80 dollars on a outdoors sheath knife. I use the tool too hard to want to spend more. I don't like the more traditional stainless steels such as AUS-8, 420HC, and 440C (not to mention the HORRENDOUS 440A) because I feel that the all else being equal, a stainless blade will bend before a carbon blade will break. I also think that carbon holds an edge at least as well, if not better, than traditional stainless, and it's much easier to hone. I don't know much about these new laminates, other than the very hard, but not so tough. They seem to be POSSIBLY too brittle for my use. That, combined with the fact that they cost a FORTUNE, means that I just won't be considering them.

- Q:What are the common coil diameters available for steel coils?

- The common coil diameters available for steel coils typically range from 24 inches to 72 inches.

- Q:How are steel coils used in the production of steel containers?

- Steel coils are an essential component in the production of steel containers. These coils, made from flat-rolled steel, are used to create the main body of the container. Firstly, the steel coils are unwound and fed into a rolling mill, where they undergo a series of processes to shape and form the steel. This includes heating the coils to a specific temperature to make them more malleable and easier to work with. The hot coils are then passed through a series of rollers that gradually reduce their thickness and lengthen them to the desired size. This process is known as hot rolling. Once the steel coils have been rolled to the required thickness, they are then cooled and cut into sheets. These sheets are then further processed to remove any imperfections or irregularities, ensuring a smooth and uniform surface. This is done through processes such as pickling, where the sheets are treated with acid to remove any scale or rust, and cold rolling, where the sheets are passed through rollers at room temperature to achieve the desired thickness and surface finish. After the sheets have been cleaned and smoothed, they are then formed into the shape of the container. This is typically done through a process called stamping, where the steel sheets are pressed into a mold using a hydraulic press. The mold determines the shape and size of the container, and the steel sheets are pressed against it with immense force, resulting in the desired container shape. Once the containers have been formed, they undergo various finishing processes such as welding, painting, and coating to enhance their durability, appearance, and resistance to corrosion. These final touches ensure that the steel containers are of high quality and meet the required standards for their intended use. In summary, steel coils play a crucial role in the production of steel containers by providing the raw material from which the containers are formed. Through a series of processes, the steel coils are shaped, cut, and formed into sheets, which are then further processed and transformed into the desired container shape. The result is a durable and reliable steel container that can be used for various applications across industries.

- Q:How are steel coils used in the manufacturing of medical equipment?

- Steel coils are used in the manufacturing of medical equipment as they provide strength, durability, and flexibility for various components. These coils are often used in the production of surgical instruments, medical devices, and diagnostic equipment where precision and reliability are crucial.

- Q:a steel abr sells for about 879 now...a mith just over 1kany suggestions on which-keyword WHICH steel item to make-which is the best-exp wise, and steel bar conservative wise.

- If members, cannonballs. If not, steel kites, I suppose. Steel Platebody only alchs for 1200, and requires 5 bars... But I stuck with steel, till 70 smithing... cheaper, and requires less coal to make....

- Q:what do you think about producebility of low density steel? for example: can density of 1020 steel (or ony others) be decreased without any loss of other properties.

- 1. A method has been developed for magnetic phase analysis of Fermanal type alloys as-quenched and after aging. 2. The upper limit of alloying to ensure the optimal mechanical properties was determined more precisely for steel 9G28Yu9MVB. For rods aged at 550°C for 16 h the aluminum content should not exceed 9.2% and the carbon content 0.92%. 3. To ensure the optimal mechanical properties of the deformed metal it is necessary to obtain a fine-grained single-phase austenitic structure after quenching. The amount of hardening phase after quenching should not exceed 15–20% (saturation magnetization around 1600 G).

- Q:What are the main factors that affect the surface quality of steel coils?

- The main factors that affect the surface quality of steel coils include the quality of raw materials used, the manufacturing process employed, the level of cleanliness and maintenance of equipment, the presence of contaminants or impurities, the coating or finishing applied, and the handling and storage conditions.

- Q:What are the different types of steel coil grades and specifications?

- There are several different types of steel coil grades and specifications, including hot rolled, cold rolled, galvanized, and stainless steel coils. Each type has its own unique properties and uses. Hot rolled coils are produced at high temperatures and are commonly used in construction and manufacturing applications. Cold rolled coils are produced at lower temperatures and have a smoother finish, making them suitable for applications that require a higher level of precision. Galvanized coils are coated with a layer of zinc to protect against corrosion, while stainless steel coils contain a high percentage of chromium for added durability and resistance to corrosion. Overall, the choice of steel coil grade and specification depends on the specific requirements of the project or application.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Galvanized Steel Coil-JIS G 3302 SGCC-0.5mm*1000mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords