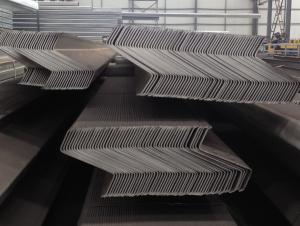

Galvanized Solar Panel Ground Mounting Bracket

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specifications

Solar Panel Mounting Brackets

1.Material:prefab C,U section steel

2.Surface:Hot dip galvanized

3.Size:as clients's requests.

Galvanized Solar Panel Mounting Brackets

| Material | Galvanized fabricated low carbon steel |

| Zinc coating | 270-600g/ m² |

| Design snow Load | 1.5KN/m² |

| Design wind Load | 55m/s or 200km/h |

| Angle of elevation | 0°-45° |

| Production Standard | TUV, GB/5237-2008 |

| Design Standard | AS/NZS 170 |

1.Material:prefab C,U section steel,steel tubes

2.Surface:Hot dip galvanized

3.Size:as clients's requiremens

4.Price: reasonable price

Packaging & Delivery

| Packaging Detail | standard export packing |

| Delivery Detail: | 20-30days |

- Q:Can a solar mounting system be used in areas with limited access to solar co-op programs?

- Yes, a solar mounting system can still be used in areas with limited access to solar co-op programs. Solar co-op programs are community-driven initiatives that help residents pool their resources to install solar panels collectively. However, even without a solar co-op program, individuals or businesses can still install solar panels using a solar mounting system. They would need to explore other options such as financing, incentives, or working directly with solar installers to make the installation financially viable.

- Q:Can a solar mounting system be installed on a rooftop with a mansard roof?

- Yes, a solar mounting system can be installed on a rooftop with a mansard roof. However, it may require specialized mounting techniques to ensure proper installation and maximize efficiency due to the unique design of a mansard roof.

- Q:How does a solar mounting system affect the roof's waterproofing?

- A solar mounting system can have an impact on the roof's waterproofing. When installing a solar mounting system, penetrations are made in the roof to secure the system, such as anchor bolts or brackets. These penetrations create potential entry points for water, which may lead to leaks if not properly sealed. Therefore, it is crucial to ensure that the mounting system is installed correctly and that proper waterproofing measures are taken to prevent any water damage to the roof.

- Q:Can a solar mounting system be used with solar tracking systems?

- Yes, a solar mounting system can be used with solar tracking systems. In fact, many solar tracking systems require a compatible mounting system to ensure proper functionality and maximize the energy output of the solar panels. The mounting system provides the necessary support and stability for the solar panels, while the tracking system allows the panels to follow the sun's movement, optimizing the amount of sunlight they receive throughout the day.

- Q:Can a solar mounting system be installed on a rooftop with a sawtooth roof?

- Yes, a solar mounting system can be installed on a rooftop with a sawtooth roof. However, the installation process might require additional considerations and adjustments to accommodate the unique design of a sawtooth roof.

- Q:Can a solar mounting system be used with solar-powered disaster relief efforts?

- Yes, a solar mounting system can definitely be used with solar-powered disaster relief efforts. These systems are designed to securely hold solar panels in place, allowing them to capture sunlight and convert it into electricity. By utilizing solar power, disaster relief efforts can have a reliable and sustainable source of energy, even in areas where the traditional power grid may be damaged or inaccessible. Solar mounting systems are versatile and can be installed on various surfaces, such as rooftops, ground mounts, or even portable structures, making them ideal for emergency situations and providing essential power for communication, medical equipment, lighting, and other critical needs.

- Q:Can a solar mounting system be used for both residential and commercial installations?

- Yes, a solar mounting system can be used for both residential and commercial installations. The same type of mounting system can be adapted and scaled to accommodate different sizes and types of solar panels, making it suitable for both residential and commercial applications. Additionally, using a single mounting system for both residential and commercial installations can help reduce costs and simplify the installation process.

- Q:Can a solar mounting system be installed on a golf course or country club?

- Yes, a solar mounting system can be installed on a golf course or country club. The wide open spaces and ample sunlight make it an ideal location for solar panels. Additionally, installing solar panels can help golf courses and country clubs reduce their carbon footprint and save on energy costs.

- Q:Can solar mounting systems be installed on flat concrete roofs?

- Yes, solar mounting systems can be installed on flat concrete roofs. However, it is important to ensure that the roof is structurally capable of supporting the weight of the solar panels and mounting system. Additionally, proper waterproofing measures need to be taken to prevent any potential leaks or damage to the roof.

- Q:Is the template and stent two or one?

- Material staff, that is, the contractor to see the words in accordance with the quota on it. The template is the contact area, the stent is the building area.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Galvanized Solar Panel Ground Mounting Bracket

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Hot Searches

Related keywords