Galvanized Scaffolding Tube Formwork Galvanized Scaffolding Tube With Low Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 set

- Supply Capability:

- 50000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Galvanized Scaffolding Tube Formwork Galvanized Scaffolding Tube With Low Price

Circular Column Formwork Outrigger For Scaffolding

Developing with new technology materials, steel formworks is no longer a must in construction concrete process. More and more buildings are established with plastic formworks. And workers love this new formworks much more.

The advantages of plastic formworks:

1.First of all--light

Yes it is the first advantage of plastic formwork. It wins the great praise of both contractors and workers.

The biggest panel is 120×1500px,weights 10.5kg only. It can be lift and set up by one person easily, which means there is no need for cranes on site.Saves a lot of cost and time.

2.Easy set up

Different size of panels can firmly locked by simply turn the special handles to 90 degree. The Panels has rib on the back, which makes the system need not traditional wood blocks and nails. The panels have holes to fit tie rod, guarantee the strength of the whole system.

4.Strength

The handles are made by high strength Nilon, each panel locked by at least 4 handles, which makes the whole system strong enough to pour 1000px walls.

5.Environment friendly

The system needs no cut and nail due to the variety size. Also it needs nearly no wood. The material can be recycled after broken, so it will not pollute the environment.

6.Consequent

Concrete does not stick to plastic formwork, thus the panels need no oil before using, and can be cleaned simply by water. The surface of the wall which build by modular formwork is smooth and without rework.

Galvanized Scaffolding Tube Formwork Galvanized Scaffolding Tube With Low Price

Galvanized Scaffolding Tube Formwork Galvanized Scaffolding Tube With Low Price

Galvanized Scaffolding Tube Formwork Galvanized Scaffolding Tube With Low Price

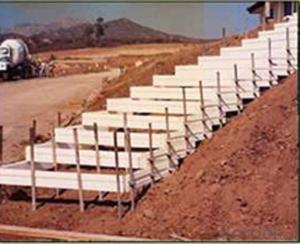

Advantage

* Good loading capacity

* Easy to assemble and dismantle

* Stable and durable thanks to its structual design & automatic welding quality

* Customized solution helps you work safe, save cost and convenient

* Excellent quality for formwork & scaffolding

Packing

in bulk or in bundle, or as requested

Shipping

15-20 Days.

Normally small orders, it needs just 15-20 business days to the port.

Galvanized Scaffolding Tube Formwork Galvanized Scaffolding Tube With Low Price

Other scaffolding & formwork products:

(1) Scaffolding System:

Including Ringlock Scaffolding System and accessories; Cuplock Scaffolding System and accessories; Kwikstage Scaffolding System and accessories; Haki Scaffolding System and accessories;

(2) Scaffolding Frame & Accessories:

Including Walk Through Frame Scaffolding; Ladder Frame Scaffolding; Accessories; we also can make scaffolding according to your samples or drawings.

(3) Scaffolding Couplers/Clamps:

We can produce all kinds of forged and pressed couplers, including British type couplers, American type couplers, German type couplers, Italian type couplers ,fence couplers, BRC coplers and so on. We also can produce according to your drawings or samples.

(4) Formwork System Scaffolding & Accessories:

Light Duty Shoring prop and Heavy Duty Shoring Prop; Wing nuts and Tie rods; RASTO clamp and so on.

FAQ Galvanized Scaffolding Tube Formwork Galvanized Scaffolding Tube With Low Price

Why Us?

We are one of the Top 500 in the world, largest construction materials supplier in China. Also we are a state-owned company and respond to every customer with large and also small orders.

We own professional manufacturers with powerful producing capacity.

Extensive and comprehensive quality control system

Full energy with affluent experience team.

- Q:Can steel frame formwork be adjusted to different sizes and shapes?

- Yes, steel frame formwork can be adjusted to different sizes and shapes. Steel frame formwork is a versatile construction tool that is designed to be easily adjustable and customizable. The frames of the formwork can be assembled and disassembled to accommodate various dimensions and shapes required for different construction projects. This flexibility allows for the construction of walls, columns, beams, and other structural elements of varying sizes and shapes. Additionally, steel frame formwork can be combined with other formwork systems to further enhance its adaptability, making it a preferred choice for many construction professionals.

- Q:What are the common forms of high-rise building construction?

- Pouring concrete. Templates can be used 3 ~ 4 times, with the old template, the site is usually used to boil water.Satisfied with

- Q:Can steel frame formwork be used for hospitality and tourism facilities construction?

- Construction of hospitality and tourism facilities can indeed utilize steel frame formwork. This construction technique, known for its versatility and durability, offers numerous advantages for building projects. Its ability to provide a strong and stable structure is particularly valuable for hospitality and tourism facilities, which often necessitate expansive open spaces and multiple floors. The utilization of steel frame formwork allows for flexibility in both design and construction. Architects and engineers can create distinctive and appealing structures that cater specifically to the needs of hospitality and tourism facilities. Furthermore, this construction technique enables faster construction times, as the steel frame can be pre-fabricated off-site and easily assembled on-site. Consequently, construction time is reduced, and disruption to the surrounding area is minimized. Moreover, steel frame formwork exhibits exceptional resistance to fire, moisture, and pests. This makes it an ideal choice for hospitality and tourism facilities that must comply with stringent safety and regulatory standards. Additionally, it provides excellent sound and thermal insulation, ensuring a comfortable and pleasant environment for guests. To summarize, steel frame formwork is a suitable construction method for hospitality and tourism facilities. Its strength, flexibility, durability, and other benefits render it an attractive option for building projects within this sector.

- Q:How does steel frame formwork handle different types of formwork leveling systems?

- Steel frame formwork is a versatile and durable option for various construction projects, and it is designed to handle different types of formwork leveling systems effectively. The steel frame provides a strong and rigid structure that can support the weight of the concrete and maintain the desired shape and alignment of the formwork. One common type of formwork leveling system used with steel frame formwork is the adjustable prop system. This system consists of adjustable props that can be extended or retracted to achieve the desired formwork level. The steel frame formwork is designed to accommodate these adjustable props, providing the necessary support and stability to ensure a level and secure formwork structure. Another type of formwork leveling system that can be used with steel frame formwork is the hydraulic leveling system. This system utilizes hydraulic jacks to adjust the formwork level. Steel frame formwork can be easily integrated with hydraulic leveling systems, allowing for precise and efficient adjustment of the formwork level. Additionally, steel frame formwork can also be used with other leveling systems such as screw jacks or leveling wedges. These systems provide flexibility in adjusting the formwork level and can be easily incorporated into the steel frame structure. Overall, steel frame formwork is compatible with different types of formwork leveling systems. Its robust structure ensures stability and support, while its versatility allows for the integration of various leveling mechanisms. This makes steel frame formwork a reliable choice for handling different types of formwork leveling systems in construction projects.

- Q:Can steel frame formwork be used for both square and rectangular column construction?

- Yes, steel frame formwork can be used for both square and rectangular column construction. The flexibility of steel frame formwork allows for easy adjustments and customization to accommodate different column shapes and sizes.

- Q:How does steel frame formwork help in reducing concrete segregation?

- Steel frame formwork helps in reducing concrete segregation by providing a strong and rigid structure that holds the concrete in place during the pouring and curing process. The steel frame formwork prevents the concrete from flowing or separating, ensuring that the aggregate and cement are uniformly distributed throughout the mixture. This helps to minimize the risk of concrete segregation, which can lead to an uneven and weaker final structure.

- Q:Can steel frame formwork be used for the construction of swimming pools?

- Yes, steel frame formwork can be used for the construction of swimming pools. It is a durable and strong material that can provide the necessary support and shape for the pool structure. Additionally, steel frame formwork allows for flexibility in design and can be easily assembled and disassembled, making it suitable for constructing swimming pools of various shapes and sizes.

- Q:Are there any restrictions on the concrete mix design that can be used with steel frame formwork?

- Yes, there are some restrictions on the concrete mix design that can be used with steel frame formwork. Steel frame formwork is a type of formwork system that is designed to support the weight of the concrete during pouring and curing. It consists of steel frames that are assembled to create a mold for the concrete. One of the main restrictions is related to the workability of the concrete mix. The concrete mix used with steel frame formwork should have a certain level of workability to ensure that it can be easily poured into the formwork and properly compacted. If the concrete mix is too stiff or too fluid, it can lead to issues such as poor compaction, segregation, or excessive bleeding. These issues can compromise the quality and strength of the final concrete structure. Another restriction is the strength of the concrete mix. The concrete used with steel frame formwork should have sufficient strength to support the weight of the formwork and the concrete itself without any deformation or failure. The strength of the concrete is determined by the mix design, which includes the proportions of cement, aggregates, water, and any admixtures. The mix design should be carefully selected to achieve the desired strength and durability of the concrete. It is also important to consider the curing requirements of the concrete mix. After pouring, the concrete needs to be properly cured to achieve its full strength and durability. Steel frame formwork can affect the curing process by providing some level of insulation, which can influence the rate of hydration and the development of strength in the concrete. Therefore, the concrete mix should be designed to account for the curing conditions associated with steel frame formwork. In addition, certain admixtures or additives may not be compatible with steel frame formwork. For example, some admixtures that accelerate or retard the setting time of the concrete may interfere with the proper installation and removal of the formwork. It is important to consider the compatibility of admixtures with steel frame formwork and consult with experts or manufacturers to ensure that the concrete mix is suitable for use with this type of formwork. Overall, while there are restrictions on the concrete mix design that can be used with steel frame formwork, it is possible to design a mix that meets these requirements. It is important to carefully consider factors such as workability, strength, curing requirements, and compatibility with admixtures to ensure the successful and efficient use of steel frame formwork in concrete construction projects.

- Q:What are the load-bearing capacities of steel frame formwork?

- The load-bearing capacities of steel frame formwork can vary based on several factors, including design, dimensions, and the quality of the steel used. Steel frame formwork is known for its strength and durability, allowing it to support heavy loads during construction projects. Typically, steel frame formwork has a load-bearing capacity ranging from 50 kN/m² to 100 kN/m². This capacity enables it to handle the weight of concrete slabs, walls, and columns, ensuring the structural integrity of the building being constructed. It's essential to mention that the load-bearing capacity of steel frame formwork should always be verified by structural engineers or construction professionals. They consider specific project requirements, local building codes, and safety factors to determine the appropriate load-bearing capacity. Furthermore, regular inspections and maintenance of the steel frame formwork are vital to maintain its strength and stability. Any signs of damage or wear should be promptly addressed to preserve the desired load-bearing capacity and ensure the safety of the construction site and workers.

- Q:Can steel frame formwork be used for both cast-in-place and precast concrete construction?

- Yes, steel frame formwork can be used for both cast-in-place and precast concrete construction. Steel frame formwork provides a versatile and durable solution that can be easily adjusted and reused for different construction projects. It ensures precise and accurate shaping of concrete elements, whether they are cast on-site or produced in a precast facility.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Galvanized Scaffolding Tube Formwork Galvanized Scaffolding Tube With Low Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 set

- Supply Capability:

- 50000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords