Galvanized Scaffolding Tube 48.3*2.5*6000mm Q235B Steel Standard EN39/BS1139 for Sale CNBM

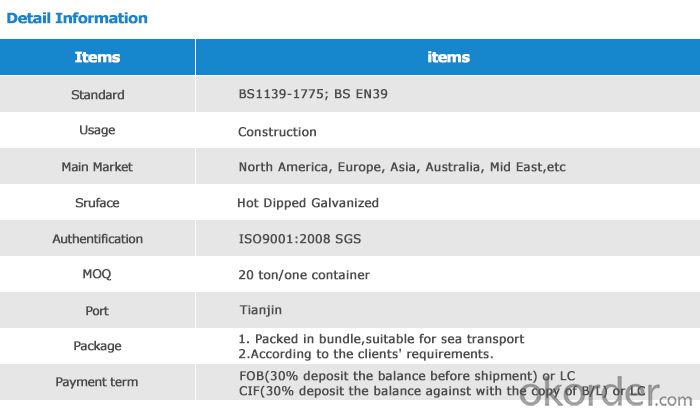

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details of Galvanized Scaffolding Tube 48.3*2.5*6000mm Q235B Steel EN39/BS1139

Material :Q235B/Q345B

Size : 48.3*2.5*6000mm

Surface treatment :Black/Painted/Galvanized

Standard:EN39/BS1139

Futures of Galvanized Scaffolding Tube 48.3*2.5*6000mm Q235B Steel EN39/BS1139

Galvanized Scaffolding Tubes confirm to BS 1139/BS EN 39 Standard. We have a big factory producing galvanized Scaffolding tubes 25,000 tons each month, and 90% of them are for export. Our scaffolding tubes are widely used in all kinds of construction site such as oil and gas industry, refinery industry and infrastructure in over 20 countries.

We have a wide range of round scaffolding tubes. If you require a specific size, such as different thickness or different length, please send us your detail requirements. Our quotation will always base on your requirements.

Hot Dipped Galvanized Scaffolding tubes are also known as scaffolding pipes, scaffolding poles, and galvanized steel tubes, round galvanized tubes.

Size: 48.3 X 2.5 X 6000mm

Zinc Thickness: 40 micron

Surface: hot Dipped Galvanized

Water Proof: according to customer requirements.

FAQ

1. What is considerations of Scaffolding installation?

There must be a fire protection measures and specialist care, safety personnel patrol inspection when electricity, gas welding work on the scaffold,

(1) scaffold frontage hurtful to prevent falling objects protection is required.

(2) During take down the scaffolding, fencing and warning signs should be set up on the ground, prohibit others person besides the operator

2.What are the certifications of your products?

Certified by SGS, BS1139, EN74, Local Test Report.

3. How long is the warranty period for your product?

Our products warranty is 2 years.

- Q:What does my earth science teacher mean when he says to do a powerpoint with Link Scaffolding,how d u do it?

- Link Scaffolding = A search found no answer. - Ask teacher to clarify.

- Q:Scaffolding installation process, construction preparation

- Construction preparation(1): steel pipe should be consistent with current national standard "carbon structural steel" (GB/T700) regulations Q235- grade steel; new steel pipe should be the product quality certificate; steel surface should be flat and smooth, no cracks, scarring, delamination, dislocation, bend, burr, indentation and scratch depth, pipe diameter deviation not more than -0.5mm, the wall thickness deviation not greater than -0.5mm, cutting slope deviation not greater than 1.7mm, the steel surface should be brushed with antirust paint; old steel corrosion depth not greater than 0.5mm, more than the prescribed steel shall not be used.(2): buckle made of malleable iron fasteners, the material should be consistent with current national standard "steel pipe scaffolding fasteners" (GB15831) regulations; old buckle inspect before use, shall not have cracks, deformation, bolt appear smooth silk must be replaced; new and old fastener must brush good antirust paint.(3) foot board: the use of 4m long wooden foot board; foot width of not less than 200mm, the thickness is not less than 50mm, both ends should be set with a diameter of 4mm galvanized steel hoop two; rotten feet can not be used.(4) safety net, paint.(5) after the inspection and acceptance of the above parts have been classified and piled up in a neat and orderly manner, no water can be accumulated.2, scaffolding erection and removal(1) scaffold erection

- Q:I know the ivy sort of glues itself to whatever surface with little sticky pads so that will take care of itself on the back of my house but can I use the existing Ivy for the wisteria to grab onto and climb up or will the wisteria be too heavy and pull the ivy down? I'd rather avoid having to build something for the wisteria to wrap itself around. Any suggestions? Thanks! : )

- No, ivy isn't that strong. One can easily unzip it from the walls. Wisteria is way too heavy for ivy. Plus you have the root competition down below. Ivy creates an incredible dense mat of roots , little grows with it. Wisteria would have quite a battle on its hands for root space and nutrients.

- Q:Sweeping rod, large cross bar, small cross bar, scissors brace, vertical pole, right angle fastener, rotating fastener, butt joint fastener, even wall piece! If there is a cantilever frame, the main beam, steel wire rope, such as pull down support

- Mobile scaffolding is the main frame, cross frame, cross diagonal brace, foot board, adjustable base and other components. The cross rod is also called the diagonal pull rod, and is a cross connecting rod which is vertically connected with the two door frames. The part of both ends of the rod part is punched with a pin hole, and the locking pin on the vertical rod of the door and the frame is locked when assembling.

- Q:there is also shrubs and trees planted on the base of the wall and 14 feet from it

- A little late to be asking that question if you already have the contract, isn't it?

- Q:hi guys i got my scaffold piercing a couple of days ago and it keeps bleeding on and off and there was dry blood but i removed it and its bleeding more what could i do step by step to keep total care of my piercing to get rid of all these problem please help it will really be appreciated

- Dab it with tissue until it stops, Try not to play with it too much and if you need to touch it, ALWAYS wash your hands before doing so. Also do hot salt water soaks (as hot as you can stand) twice a day and it'll heal nicely in no time :)

- Q:Should the WWE put John Cena in a triple threat thumbtack scaffold cage of death with New Jack & Necro Butcher?

- that would be great natural born killas playing the whole match

- Q:Okay so I got a scaffold piercing about 5 days ago now. I've been cleaning it with Claire's piercing stuff. What I do is I pour it onto a little bit of loo roll and squeeze it all out on where the holes are. I have not been twisting it at all, but my friend told me that I should soak it in warm salty water and twist it twice a day. I have no idea what to do now as I have researched it and some people say that I shouldn't twist it because it will drag more bacteria into it and could get it infected. Also I have massive scabs around both ends of the bar, I've tried to pick them off as they are pretty uncomfortable, but it didn't work as they are rock solid, so how do I get these off? I have no idea what to do, my piercer didn't say anything about twisting it just cleaning it twice a day. Oh and if it helps I'm 13:) Thanks. X

- Why are you using Claire's crap? You need to be doing sea salt soaks twice a day for 5-10 minutes each soak with 1/4th of a teaspoon of non-iodized sea salt to 8oz of hot water. Don't twist them as that drags in crust and bacteria and tears up the inside of the piercing. Stop trying to pick stuff off from your ear and go have a reputable piercer check out the scabbing, it could be crust it could be something wrong. If your piercer didn't tell you to do sea salt soaks to keep it clean go to a better piercer.

- Q:At 16 I took my bros 16 gauge piercing needle and pierced my left cartilage and it didn't hurt at all.... and I have a tattoo as well and I laughed through it. So pain isn't huge when it's a small amount.

- once you get it pierced do no longer stressful up bc its going to harm like 10 situations extra. stay comfortable and actual do now not sleep on it in view which you will awaken day after today with a swollen ear and in discomfort. sparkling it thrice an afternoon for 12 weeks. And basically a reminder cartilage piercings do take a together as to heal. Mine took a pair of 365 days in a a million/2 to absolutely heal. meaning the place i became into waiting to sleep on it and not harm.the place i became into waiting to pass it around without it getting contaminated minutes later. you may haven't any problem with it as long as you're looking after it =) And from a a million to 10 i say its between a 7 and eight once you get it pierced bc it does throb after.

- Q:If you have two workers say standing on a scaffolding, their are downward forces from the weight of the workers along with the weight of the scaffold, and upward forces from tension suspending the scaffolding in place. The opposite forces add to zero and thus the scaffolding remains at rest.My question has to do with what would occur if more/less workers were on the scaffolding. It appears to me that the scaffolding would always remain at rest. Would there always be a ΣF=0 regardless of the amount of workers? As the decreases in weight from removing a worker would also cause the tension force to be weaker? And vice versa if there were more workers?I

- You are correct so long as the scaffolding is not allowed to move. I.e. the cables suspending it are locked and not unwinding from their spools as more workers get on. More weight added would necessarily increase the tension in this type of case. However, if, when another worker got on and the tension could not increase for what ever reason, a downward acceleration would take place that is proportional to the worker's weight. Hope that clears things up.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Galvanized Scaffolding Tube 48.3*2.5*6000mm Q235B Steel Standard EN39/BS1139 for Sale CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords