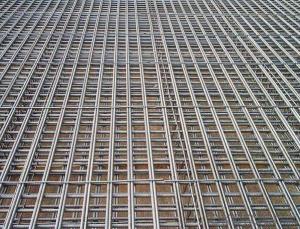

Galvanized Reinforcement Concrete steel wire mesh

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 20000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Steel bar welded wire mesh Introduction:

Steel bar welded wire mesh is also called welded steel fabric, steel welding nets, steel welding nets, steel bar welded mesh, steel mesh and so on. Is the longitudinal reinforcement and transverse reinforcement were arranged in a certain interval and at right angles to each other, all the intersections are welded together.

Steel bar wire mesh Description:

Material: low carbon steel bar, thread steel bar, thread rod

1.Mesh width: 0.5 m - 2.4 m;

2.Wire diameter3.0-10.0 (mm);

3.Apertures: 50x50mm,100x100mm,150x150mm,200x200mm

4.length: below 12m

5.Application: construction,bridge,tunnel

6.Mesh size: 6 x2.4m

Product feature:

1.It has a strong and firm body, can bear the high pressure from the concrete and exterior.

The reinforcing mesh can save much man-haur, reduce the material cost in the process.

2.The reinforcing mesh can design by the project requirement, improve the efficiency and

bond to the concrete can meet the special construct needs.

It is widely use in airport, tunnel, bridge, highway and wharf, also in the construction of building floor, wall, roof and balcony.

Applications:

1. Concrete footpaths

2. Precast Panel construction

3. Construction reinforcement

4. Residential slabs and footings

5. Industrial and commercial ground slabs

Specification:

| WIRE DIAMETER | MESH | |

| Inch | MM | |

| 1.5mm | 1/2" X 1/2" | 12.7mm X 12.7mm |

| 2mm | 1" X 1" | 25.4mm X 25.4mm |

| 3mm | 1" X 1" | 25.4mm X 25.4mm |

| 3mm | 1-1/4" X 1-1/4" | 31.7mm X 31.7mm |

| 4mm | 1-1/2" X 1-1/2" | 38mm X 38mm |

| 4mm | 1-1/2" X 1-1/2" | 38mm X 38mm |

| 4mm | 1-1/2" X 1-1/2" | 38mm X 38mm |

| 2mm | 2" X 2" | 50.8mm X 50.8mm |

| 3mm | 2" X 2" | 50.8mm X 50.8mm |

| 3mm | 2" X 2" | 50.8mm X 50.8mm |

| 4mm | 2" X 2" | 50.8mm X 50.8mm |

| 4mm | 2" X 2" | 50.8mm X 50.8mm |

| 4mm | 2" X 2" | 50.8mm X 50.8mm |

| 4mm | 2" X 2" | 50.8mm X 50.8mm |

| 5mm | 2" X 2" | 50.8mm X 50.8mm |

| 5mm | 2" X 2" | 50.8mm X 50.8mm |

| 6mm | 4" X 2" | 101.6mm X 50.8mm |

| 6mm | 4" X 4" | 101.6mm X 101.6mm |

Delivery Time:

Within one week for one 20' container.

- Q:What are the different sizes available for steel wire mesh?

- Steel wire mesh comes in a wide range of sizes to meet different needs and applications. The sizes of steel wire mesh are typically specified based on the wire diameter and the mesh opening size. The wire diameter refers to the thickness of the individual wires used in the mesh. It can vary from very thin wires, like 0.2mm, to thicker wires of 5mm or more. The choice of wire diameter depends on the specific application's required strength and durability. The mesh opening size refers to the distance between adjacent wires in the mesh. It can range from very fine mesh, with 0.5mm openings, to larger mesh with openings measuring several centimeters. The selection of mesh opening size depends on the desired level of visibility, air flow, or filtration needed for the application. In addition to the wire diameter and mesh opening size, the overall dimensions of steel wire mesh can also differ. It is available in standard sheet sizes, such as 4ft x 8ft or 5ft x 10ft, or it can be custom-cut to specific dimensions according to customer requirements. In conclusion, the various sizes of steel wire mesh offer flexibility and versatility to meet diverse industrial, commercial, and residential needs, including fencing, concrete reinforcement, filtration, animal enclosures, and more.

- Q:How does steel wire mesh perform in terms of vibration resistance?

- Steel wire mesh performs well in terms of vibration resistance due to its inherent strength and rigidity. The interlocking structure of the wires in the mesh provides stability and prevents excessive movement or deformation under vibrations. This makes it an excellent choice for applications where vibration resistance is crucial, such as in construction, industrial equipment, and automotive industries. Additionally, the high tensile strength of steel wire mesh allows it to withstand vibrations without breaking or losing its structural integrity. Its durability and resistance to fatigue make it capable of withstanding repetitive vibrations over time. Overall, steel wire mesh is known for its excellent performance in terms of vibration resistance, making it a reliable and long-lasting solution for various applications.

- Q:What are the different mesh shape options available for steel wire mesh?

- Steel wire mesh offers a variety of mesh shape options, each with its own unique characteristics and advantages. Here are some of the most common options: 1. Square Mesh: This is the most widely used option, featuring square openings formed by intersecting wires at right angles. It provides equal strength in both directions and is commonly used for filtration, screening, and reinforcement. 2. Rectangular Mesh: Similar to square mesh, this option has rectangular-shaped openings that allow for different dimensions in the horizontal and vertical directions. It offers versatility for applications such as partitions, fencing, and architectural designs. 3. Diamond Mesh: Also known as rhomboidal mesh, this option has diamond-shaped openings formed by diagonal wires. It offers excellent structural stability and is often used for security fencing, animal enclosures, and gabion walls. 4. Hexagonal Mesh: Also called hex mesh or chicken wire, this option features hexagonal-shaped openings formed by continuous wires. It provides flexibility and is commonly used in agricultural applications such as poultry enclosures, garden fencing, and small animal cages. 5. Welded Mesh: This type of mesh is created by electrically welding the intersection points of the wires, resulting in a rigid and durable shape. It offers high strength and is widely used in construction, concrete reinforcement, and infrastructure projects. 6. Expanded Metal Mesh: Produced by cutting and stretching a sheet of metal, this option creates a pattern of interconnected diamond-shaped openings. It offers excellent visibility, ventilation, and light transmission, making it suitable for walkways, catwalks, and grating. These are just a few examples of the many mesh shape options available for steel wire mesh. The choice depends on specific requirements, including strength, durability, visibility, and aesthetics.

- Q:Can steel wire mesh be used for industrial applications?

- Absolutely, industrial applications can definitely make use of steel wire mesh. Steel wire mesh is an incredibly adaptable and long-lasting material that can endure extreme temperatures, substantial loads, and challenging environments. It is widely employed in multiple sectors, including construction, mining, agriculture, manufacturing, and transportation. When it comes to construction, steel wire mesh serves the purpose of reinforcing concrete structures, providing them with the necessary strength and stability. It is also utilized in fencing and security applications to establish barriers and enclosures. In the mining industry, steel wire mesh is employed for the screening, sorting, and separation of materials. Additionally, it finds use in the oil and gas industries for filtration purposes. Moreover, the agricultural sector benefits from the applications of steel wire mesh, which is employed for animal enclosures, bird cages, and crop protection. In manufacturing, steel wire mesh is utilized for sieving, filtering, and straining processes. It can be incorporated as conveyor belts or utilized as support structures in machinery and equipment. The transportation industry greatly relies on steel wire mesh for diverse purposes. It is involved in the production of automotive components, such as filters and grilles. Furthermore, it plays a crucial role in cargo containment within trucks and trailers. Overall, steel wire mesh possesses exceptional versatility and can be tailored to meet specific requirements in various industrial fields. Its strength, durability, and flexibility make it the preferred choice for a wide range of industrial applications across different sectors.

- Q:What are the different wire shapes available in steel wire mesh?

- The different wire shapes available in steel wire mesh include plain weave, twill weave, Dutch weave, and reverse Dutch weave.

- Q:Can steel wire mesh be used for air vents?

- Yes, steel wire mesh can be used for air vents. Steel wire mesh is a versatile material that can effectively prevent the entry of larger debris, insects, and animals while allowing air to flow through. It is commonly used in air vents to provide ventilation and maintain proper airflow in various applications such as HVAC systems, industrial facilities, and residential homes. The durability and strength of steel wire mesh make it an ideal choice for air vents as it can withstand harsh weather conditions, resist corrosion, and provide long-lasting performance. Additionally, steel wire mesh can be easily customized to fit different shapes and sizes of air vents, ensuring a secure and efficient ventilation system.

- Q:How is steel wire mesh used in animal enclosures?

- Steel wire mesh is commonly used in animal enclosures to provide a secure and durable barrier. It is used to create fences, cages, and enclosures that effectively contain animals while allowing visibility and ventilation. The strength and resilience of steel wire mesh ensure that animals are safely contained, preventing them from escaping and keeping potential predators out. Additionally, the small openings in the mesh prevent animals from poking their heads or limbs through, minimizing the risk of injury. Overall, steel wire mesh plays a crucial role in maintaining the safety and well-being of animals in enclosures.

- Q:Can steel wire mesh be recycled?

- Yes, steel wire mesh can be recycled. Steel is one of the most commonly recycled materials in the world, and wire mesh made from steel can also be recycled. The recycling process involves collecting the used wire mesh, melting it down, and reforming it into new steel products. This not only helps to reduce waste and conserve resources but also saves energy as recycling steel requires less energy compared to producing steel from virgin materials. Therefore, if you have steel wire mesh that is no longer needed, it is recommended to recycle it rather than disposing of it in the trash.

- Q:Is steel wire mesh suitable for ballast or retaining walls?

- Steel wire mesh is not typically suitable for ballast or retaining walls on its own. Ballast and retaining walls require materials that have sufficient strength, durability, and stability to withstand the forces exerted on them. While steel wire mesh can be used as a reinforcing material in combination with other materials, such as concrete, it is not typically used as the primary material for ballast or retaining walls. For ballast walls, which are used to support tracks or roadbeds, materials such as crushed stone or gravel are commonly used. These materials provide stability and drainage while ensuring the proper distribution of load and forces. Retaining walls, on the other hand, are designed to hold back soil or other materials and require materials with high structural integrity. Steel wire mesh alone may not have the necessary strength and stability to support the lateral pressure exerted by the retained material. However, steel wire mesh can be used as a reinforcement within a retaining wall structure, typically in combination with concrete or other materials, to enhance its strength and stability. In summary, while steel wire mesh can play a role in the construction of ballast or retaining walls as a reinforcing material, it is not typically suitable as the primary material for these types of structures due to its limited strength and stability.

- Q:What are the different wire gauges used in steel wire mesh?

- Steel wire mesh is available in various wire gauges, which refers to the thickness of the wire used in the mesh. The wire gauges commonly used in steel wire mesh range from 6 to 30. The lower the gauge number, the thicker the wire. For heavy-duty applications, such as industrial fencing or security barriers, lower gauge wires like 6 or 8 are preferred. These thicker wires provide enhanced strength and durability. Medium-duty applications, such as agricultural fencing or animal enclosures, typically use wire gauges ranging from 10 to 14. These gauges strike a balance between strength and flexibility, making them suitable for a variety of purposes. For lighter applications, such as decorative purposes or small animal cages, higher gauge wires like 20 to 30 are commonly used. These thinner wires are more pliable and easier to work with, while still providing adequate support for their intended use. It is important to select the appropriate wire gauge based on the specific requirements of the project or application. Factors such as the desired level of security, intended use, and environmental conditions should be considered when determining the most suitable wire gauge for steel wire mesh.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Galvanized Reinforcement Concrete steel wire mesh

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 20000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords