Galvanized or Alu-zinc Steel PPGI/Color coated steel plate/Cold Rolled/PE

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Application of Galvanized or Alu-zinc Steel PPGI:

Construction | Outside | Workshop, agricultural warehouse, roof panel, wall panel in steel structure in warehouse,corrugated roof |

| Inside | factories exhibition hall,doorcase, light steel roof structure, folding screen, elevator, stairway | |

Electrical appliance | Refrigerator, washer, switch cabinet, instrument cabinet, air conditioning, micro-wave oven, bread maker | |

Furniture | Central heating slice, lampshade, chifforobe, desk, bed, locker, bookshelf | |

Carrying trade | Exterior decoration of auto and train, clapboard, container, isolation lairage, isolation board | |

Others | Writing panel, garbage can, billboard, timekeeper, typewriter, instrument panel, weight sensor, photographic equipment | |

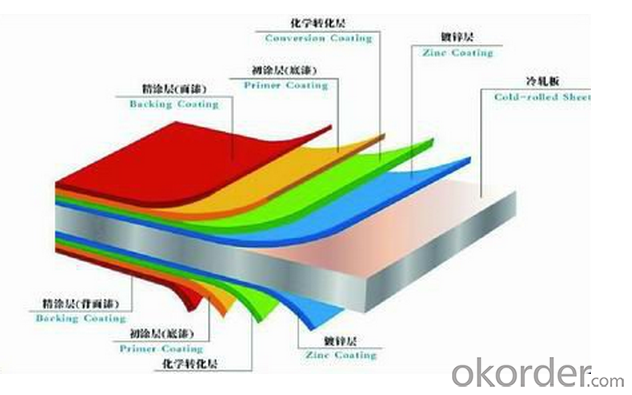

2.Features of Galvanized or Alu-zinc Steel PPGI:

With excellent cold-rolling steel strips as a base material, it has the advantages of

* Good manufacturing performance

* High impact resistance

* Uniform plating thickness

* High adhesive force

* No peeling after forming

* High corrosion resistance

3.Details of Galvanized or Alu-zinc Steel PPGI:

Base Material | Al-Zn Galvanized Steel Coil.SGLCC |

Top Side | 15-25 microns |

Back Side | 5-8 microns |

Width | 700-1250mm |

Thickness | 0.3-1.0mm ,thickness tolerance: +/- 0.02mm |

Al-Zn Coating | 30-150g/sq.m |

Coil ID | 508mm&610mm |

Color | All RAL Color,or be customized |

Spangle | Regular/Zero/Big |

4.Galvanized or Alu-zinc Steel PPGI Image:

Packaging Details:Standard seaworthy packing

Delivery Detail: within 15-30 days

Packing &Delivery

Packing detail: 1. Metal Band Strapping

2. Outside Diameter Ring

3. Label 4. Protective Steel Sheet

5. Water and Rustproof paper 6. Steel Sheet

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your Warranty?

Warranty: 1-Year for the whole light. Warranty is based on correct storage, installation, using and maintenanc

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q:How are steel coils used in the production of rail tracks?

- Steel coils are used in the production of rail tracks as they are processed and shaped into long sections known as rails. These coils are first uncoiled and then heated, allowing them to be rolled and formed into the desired rail shape. The resulting rails are then cut to the required length and undergo further processes such as straightening and finishing to ensure their strength, durability, and suitability for use in railways.

- Q:I had a damascus steel katana made for me and was wondering if I could put gun blue on it to make the steel black and it still work right

- There okorder , the true Damascus is a region of spain, which is similar to getting swords made in Pakistan

- Q:What are the common coil surface treatments?

- The common coil surface treatments include galvanization, electroplating, painting, and powder coating.

- Q:What are the disadvantages of using steel coils?

- One disadvantage of using steel coils is their high weight and bulkiness, which can make transportation and handling more difficult and costly. Additionally, steel coils are prone to rust and corrosion, requiring proper maintenance and protective coatings to prevent deterioration. Lastly, steel coils can be expensive to produce and purchase, making them less cost-effective compared to alternative materials in certain applications.

- Q:How are steel coils used in the manufacturing of steering systems?

- Steel coils are used in the manufacturing of steering systems as they provide the necessary strength and durability required for the components of the system, such as steering columns, gears, and shafts. These coils are shaped and formed into various parts through processes like cutting, bending, and welding, ultimately contributing to the overall stability and functionality of the steering system in vehicles.

- Q:What are the common uses of coated steel coils?

- Common uses of coated steel coils include roofing, siding, automotive parts, appliances, and building materials. The coating on the steel helps to protect it from corrosion and enhances its durability, making it suitable for various applications in industries such as construction, manufacturing, and transportation.

- Q:Which movie is better and why?I say Man of Steel!

- Captain America: The First Avenger

- Q:How are steel coils used in the manufacturing of automotive body panels?

- Steel coils are used in the manufacturing of automotive body panels by being processed and shaped into the desired form through techniques like stamping or roll forming. These coils provide the raw material for creating strong and durable body panels, ensuring the vehicle's structural integrity and safety.

- Q:Can steel coils be coated with magnetically attractive materials?

- Yes, steel coils can be coated with magnetically attractive materials. This process is commonly known as electromagnetic coating or magnetic coating, where a thin layer of magnetically attractive material, such as iron or nickel, is applied onto the surface of the steel coil. This coating enhances the magnetic properties of the steel, making it more responsive to magnetic fields and enabling it to attract or be attracted by magnets.

- Q:I want to purchase a set of knives made of carbon steel and want to be able to store them on a magnetic knife strip for handy access, I just wasn't sure if this alloy would stick to a magnet????Thanks

- Carbon steel knives will stick to a magnet. Stainless steel may not.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Galvanized or Alu-zinc Steel PPGI/Color coated steel plate/Cold Rolled/PE

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords