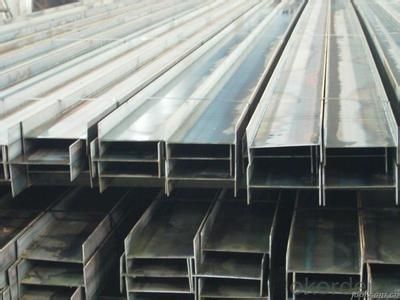

Galvanized Hot Rolled Channel Steel (UL, SGS, IEC and CE)

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4000 PCS

- Supply Capability:

- 38000 PCS/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Galvanized Hot Rolled Channel Steel (UL, SGS, IEC and CE) Details

Standard: | AISI,ASTM,BS, DIN,GB,JIS | Dimensions: | 41*21*2.0 | Grade: | steel |

Place of Origin: | China (Mainland) | Brand Name: | CNBM | Model Number: | BSC-BS |

Shape: | C Channel | Application: | construction material or bracket | Perforated Or Not: | Is Perforated |

color: | Customized | certificates: | UL, NEMA, CE, IEC, SGS and ISO9001-2008 | business model: | manufacturer and exporter |

finish: | HDG/Pre-galvanized/Powder Coating/Electro | ||||

Packaging & Delivery

Packaging Detail: | Standard packaging or customized packaging |

Delivery Detail: | Usually within 20 days |

Galvanized Hot Rolled Channel Steel (UL, SGS, IEC and CE) Specifications

1. Specialized manufacturer and exporter

2. UL, cUL, CE, IEC, TUV and SGS

3. ISO9001-2008

Galvanized Hot Rolled Channel Steel (UL, SGS, IEC and CE) Pictures

- Q:How do steel channels contribute to the overall cost savings of a structure?

- Steel channels contribute to the overall cost savings of a structure in several ways. Firstly, steel channels are lightweight yet strong, allowing for the use of smaller and lighter foundations, resulting in reduced material and labor costs. Additionally, steel channels can be prefabricated off-site, which saves time and money during the construction process. Moreover, steel channels have a long lifespan, requiring minimal maintenance and repair, leading to long-term cost savings. Finally, steel channels are recyclable, reducing the environmental impact of a structure and potentially providing financial benefits through the resale value of the material.

- Q:What are the guidelines for steel channel installations in corrosive environments?

- When installing steel channels in corrosive environments, it is important to follow specific guidelines to ensure the longevity and durability of the steel. Here are some guidelines to consider: 1. Material Selection: Choose a steel channel material that is specifically designed for use in corrosive environments. Stainless steel or galvanized steel are often recommended due to their resistance to corrosion. 2. Protective Coatings: Apply appropriate protective coatings to the steel channel to prevent corrosion. This can include anti-corrosion paints, epoxy coatings, or zinc-rich coatings. The coating should provide a barrier between the steel and the corrosive environment. 3. Proper Ventilation: Adequate ventilation is crucial in corrosive environments to minimize the accumulation of corrosive gases or chemicals. Ensure that the installation allows for proper airflow and ventilation to prevent the buildup of corrosive elements. 4. Regular Maintenance: Regularly inspect and maintain the steel channel installation to identify any signs of corrosion or damage. Promptly address any issues by cleaning, repairing, or replacing affected sections to prevent further corrosion. 5. Avoid Contact with Dissimilar Metals: Avoid direct contact between the steel channel and dissimilar metals, as this can create galvanic corrosion. Use insulating materials or proper coatings to separate different metals if they must be in close proximity. 6. Drainage: Ensure proper drainage of any liquid or moisture that may come into contact with the steel channel. Standing water or moisture can accelerate corrosion, so design the installation to allow for effective drainage. 7. Professional Consultation: Consult with professionals or corrosion engineers who have expertise in dealing with corrosive environments. They can provide specific guidance based on the unique conditions of the environment and recommend appropriate measures to protect the steel channel. Following these guidelines can help minimize the risk of corrosion in steel channel installations in corrosive environments, ensuring their long-term performance and integrity.

- Q:Can steel channels be used in high-temperature applications?

- Certainly! Steel channels are capable of being utilized in applications that involve high temperatures. Steel possesses exceptional heat resistance and can endure high temperatures without compromising its strength or structural integrity. Nonetheless, it is crucial to choose the appropriate kind of steel channel that is specifically engineered for high-temperature environments. High-temperature alloys, like stainless steel or heat-resistant steel, are commonly employed in scenarios where the temperature surpasses the capabilities of standard carbon steel. These alloys contain higher levels of chromium, nickel, and other elements that provide enhanced resistance against oxidation, corrosion, and thermal stress. Consequently, steel channels fabricated from these alloys are well-suited for utilization in high-temperature applications such as furnaces, boilers, exhaust systems, and industrial ovens.

- Q:Are steel channels suitable for seismic retrofitting?

- Indeed, seismic retrofitting can be accomplished using steel channels. Due to their exceptional strength and ductility, steel channels are frequently employed in seismic retrofitting endeavors. They prove especially useful in regions prone to significant seismic activity, as they can fortify and bolster existing structures. By absorbing and dispersing seismic forces, steel channels significantly enhance the structural stability and functionality of a building during an earthquake. Moreover, their effortless installation and seamless integration into preexisting structures render them a highly favored choice for seismic retrofitting initiatives. All in all, steel channels present themselves as a dependable and appropriate alternative for seismic retrofitting purposes.

- Q:Are steel channels suitable for use in the construction of rooftop structures?

- Yes, steel channels are suitable for use in the construction of rooftop structures. Steel channels are known for their strength and durability, making them an excellent choice for supporting the weight of rooftop structures. They can withstand heavy loads and provide stability and structural integrity to the construction. Steel channels are also resistant to weather elements, such as rain, wind, and snow, which are common on rooftops. Moreover, steel channels can be easily fabricated and installed, making them a cost-effective and efficient option for rooftop construction. Overall, steel channels offer numerous advantages, making them a suitable choice for use in the construction of rooftop structures.

- Q:What are the different methods of protecting steel channels from fire?

- There are several methods available to protect steel channels from fire. One common method is to apply a fire-resistant coating or paint to the surface of the steel channels. These coatings are designed to provide a protective barrier that can withstand high temperatures and prevent the steel from reaching its critical temperature, which is when it begins to lose its structural integrity. These coatings can be applied through various techniques such as spraying, brushing, or rolling. Another method is to encase the steel channels in fire-resistant materials such as concrete or gypsum board. This creates a physical barrier that insulates the steel from the heat of the fire, preventing it from reaching its critical temperature. This method is commonly used in construction projects where fire resistance is a critical requirement. Intumescent coatings are another effective method of protecting steel channels from fire. These coatings are specially designed to expand when exposed to high temperatures, forming an insulating char layer that protects the steel from the fire. Intumescent coatings can be applied as paints or sprays and are commonly used in buildings, particularly in areas where steel channels are exposed to fire risks. In addition to these methods, fireproofing materials such as fireproof wraps or blankets can be used to protect steel channels. These materials are typically made from fire-resistant fibers or fabrics and are wrapped around the steel channels to provide insulation and prevent the transfer of heat. Finally, proper fire safety measures such as installing fire suppression systems, smoke detectors, and fire alarms in the vicinity of steel channels can also help protect them from fire. These measures can help detect and control fires at their early stages, minimizing the risk of damage to the steel channels. Overall, there are various methods available to protect steel channels from fire, ranging from coatings and encasements to fireproofing materials and fire safety systems. The choice of method depends on factors such as the specific requirements of the project, the level of fire protection needed, and the budget constraints.

- Q:How are steel channels used in construction?

- Steel channels are commonly used in construction to provide structural support in various applications such as framing, bracing, and reinforcing. They are typically used to create beams, columns, and trusses, which offer stability and strength to buildings and other structures. Additionally, steel channels are used as lintels to support openings in walls and as tracks for sliding doors or windows. Overall, steel channels play a crucial role in enhancing the structural integrity and durability of construction projects.

- Q:Do steel channels have any specific load distribution characteristics?

- Yes, steel channels have specific load distribution characteristics. They are commonly used in construction and engineering applications to distribute loads evenly across their cross-sectional area. The shape of steel channels allows for efficient transfer of loads, providing strength and stability to structures. Additionally, the design of steel channels can be optimized for specific load distribution requirements, making them versatile in various structural applications.

- Q:How to connect channel steel and round steel?

- Vertical welding of channel steel and round bar axis:First, the channel steel, channel cut, need to connect the length of the arc shaped gap, and then again and round steel arc surface welding, welding before the two kinds of materials to rust, and full welding.

- Q:What is the weight of a steel channel?

- The weight of a steel channel is determined by a range of factors, including its dimensions and thickness. Typically, steel channels are quantified based on their weight per foot or weight per meter. To ascertain the weight of a steel channel, it is necessary to possess knowledge regarding its dimensions, encompassing the height, width, and thickness. Through the utilization of the suitable formula or referring to a steel weight chart, you can ascertain the weight of a steel channel.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Galvanized Hot Rolled Channel Steel (UL, SGS, IEC and CE)

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4000 PCS

- Supply Capability:

- 38000 PCS/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords