Galvanized Gabions net PVC Coated Gabions net for River Bank Bridge

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 888 m²

- Supply Capability:

- 280000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Galvanized Gabions net descriptions:

Galvanized Gabion is rectangular woven wire mesh baskets filled with rock to form flexible, permeable, monolithic structures such as retaining walls for commercial, industrial and road projects. They are also used for erosion control, bank stabilization, architectural and urban design features, noise attenuation structures and weirs.

Features of Galvanized Gabions net descriptions:

Material: low carbon steel wire, galvanized wire

Surface Treatments: hot dip galvanizing, PVC Coated, galvanized aluminum alloy and so on

Applications:Control and guide of water or flood;Flood bank or guiding bank

Preventing of rock breaking;Water and soil protection;Bridge protection;Strengthening structure of soil

Specification of Galvanized Gabions net descriptions::

Specification (mm) Diameter of wire (mm) Inside Diameter/Outside Diameter(mm) Max Wide Cut(m) 60X80 φ2.0-2.8 φ2.0/3.0-2.8/3.8 4.3 80X100 φ2.2-3.2 φ2.2/3.2-3.0/4.0 4.3 80X120 φ2.2-3.2 φ2.2/3.2-3.0/4.0 4.3 100X120 φ2.4-3.5 φ2.4/3.4-3.2/4.2 4.3 100X150 φ2.4-3.5 φ2.4/3.4-3.2/4.2 4.3 120X150 φ2.7-4.0 φ2.7/3.7-3.5/4.5 4.3 |

Production description of PVC Coated Gabions net :

PVC coated gabion or also called plastic gabion which enjoys many excellent advantages, such as corrosion resistance, simple installation, easy transportation and installation, weather proof under natural destroy, no collapse even under big scope of deforming, good permeation can prevent the damage by hydrostatic. Besides these, plastic gabion is also good for plant growing and it mixed to form a integrity with the natural environment.

Features of PVC Coated Gabions net:

* Economic. Just fill the stone into the gabions and seal it.

* Simple installation. No special technology needed.

* Weather proof under natural destroy, corrosion resistant.

* No collapse even under big scope of deforming.

* Sludge in the stones is good for plant growing. Mixed to form a integrity with the natural environment.

* Good permeation can prevent the damage by hydrostatic.

* Less transport freight. It can be folded together for transport and further installation.

Applications:* Control and guide of water or flood * Flood bank or guiding bank * Preventing of rock breaking* Water and soil protection* Bridge protection * Strengthening structure of soil*

Protection engineering of seaside area.

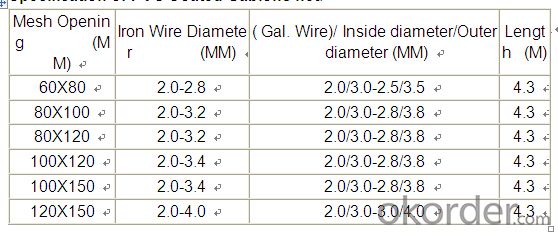

Specification of PVC Coated Gabions net:

|

PVC Coated Gabion

Introduction of CNBM

China National Building Materials (Group) Corporation (CNBM) is a state-owned enterprise in charge of administrative affairs in China building materials industry. Established in 1984, CNBM is a large group corporation of building materials with total assets of RMB 25 billion and a total staff of 30,000. Now CNBM owns more than 200 subsidiaries in and abroad the country, including wholly-owned corporations and joint ventures.

FAQ of geosynthetics :

What is geosynthetics ?

Geosynthetics form a perfect erosion control fabric used extremely widely in civil engineering to stabilize and reinforce slopes and soil under or next to roads, railways, dams, water reservoirs etc.. They can be easily applied which minimizes the time of construction, as well as they limit the resources and materials necessary.

What kinds of geosynthetics we have ?

Non-woven geotextile, geogrids, geocells, GCL, Geomembranes, Geonets, Geocomposites etc .

What is the geosynthetics used for ?

Hydraulic

Lagooning and Water Treatment, Ornamental Ponds, Golf Courses

Aquaculture and Desalination,Water Lagoons,Tanks, Reservoirs, Liquid Waste,Floating Cover Solutions, Drainage and Filtration

Environment

Tailing ponds, Leach mining,Landfills,Landfill Capping,Protection against corrosion,Vertical Barriers

Civil Works

Erosion Control,Secondary Containment,Tunnels,Linear and Surface Works,Consolidation of Margins,Soil Reinforcement,Soil Separation.

Building - Parkings,Roofing,Soundproofing

- Q:What material is used for waterproofing of tarpaulin

- Regardless of the construction or finished products are toxic, due to organic materials, it will form a separation layer, partition structure of poor wear resistance, must be a protective layer of solid, not hollowing, but requires the base surface moisture content of less than 8% overlap requirements No interface to form a seamless body thickness control easy to control the local thickness difficult to control

- Q:Roof membrane waterproof construction process, what should be noted that?

- Coil ply attention Paving direction, slope less than 3%, parallel and roof paving, slope greater than 15% or roof vibration, perpendicular to the roof paving. Slope between 3% to 15%, can be parallel to the vertical; membrane waterproof roof slope should not be greater than 25%. The upper and lower layers may not be piled on each other.

- Q:Rigid (concrete) waterproof roofing shop SBS coil can brush a layer of waterproof paint before?

- Second, the completion of the construction of the membrane and the acceptance of qualified, should do the protection of finished products, it is recommended to use cement mortar to do protective layer, construction should pay attention to the surface should be smooth pressure, and set the surface sub-grid, 1 m2. If the use of block material to do the protective layer, the sub-grid area should not be greater than 100 square meters, sub-grid width should not be less than 20mm; if the use of fine stone concrete protective layer, the sub-grid area should not be greater than 36 square meters. Note: Regardless of which protective layer is used, a separation layer should be provided between the waterproofing layer and the protective layer.

- Q:Slope roof drains do not need to be waterproof

- When installing a waterproof board, when the width of a waterproof board is not enough, to be placed side by side, it should be noted that the gap between the board and the plate will provide potential space for root growth.

- Q:What is PE waterproof cloth and PVC tarpaulin

- Waterproof cloth product features and the use of attention 1. Has a waterproof, mildew function, and a light material, high tensile strength, Naisuan Jian, high temperature, easy to wash and so fold the characteristics of folding; 2. This product should be used in the process should avoid sharp impact with the sharp metal; 3. If the product is damaged, can be used to repair glue.

- Q:What are the materials used in the ceiling?

- Kitchen bathroom ceiling material 2: aluminum plate material ????Aluminum buckle board is based on aluminum alloy as the main substrate, through the process to get the finished product, and now the aluminum plate in the use of integrated ceiling in the larger. In the home improvement specifications are generally 300MM * 300MM, 300 * 450mm, 300 * 600mm and other different sizes, because of its excellent board layer, with noise, heat insulation, light weight characteristics, while its color is also more Kind of choice, to meet the different needs of consumers.

- Q:Can acrylic materials be perforated? How to do waterproof after punching?

- Or in the back with glass adhesive paste anti-corrosion nine PCT board (if the hole is flat, Anti-corrosion nine PCT is to remove the other side of the paste surface with asphalt anti-corrosion paint brush)

- Q:Js waterproof coating without powder can brushing

- 3. Construction: brush with a brush or brush directly to the JS waterproof coating on the base surface, the intensity of the use of uniform, can not leak; if used for moisture, just brush a layer; for waterproof, To three layers. When the first layer of JS waterproof coating dry to just sticky hands (usually 1-2 hours), you can brush the second layer, every two layers of brushing direction should be straight to the intersection;

- Q:FRP finished brush on what can be waterproof do not fade

- On the surface of the gel coat it is, a lot of gel coat points, the specific performance of what you want, you can communicate with the supplier

- Q:Finished house bathroom waterproof household acceptance should be how to accept?

- 5: the use of construction stubs should be along the direction of the flow of water, lap width of not less than 100mm, the use of two or more fiberglass cloth up and down when the overlap should be staggered width of one-half.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Galvanized Gabions net PVC Coated Gabions net for River Bank Bridge

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 888 m²

- Supply Capability:

- 280000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products