Galvanized Gabion Box for Civil Engineering 2mx1mx1m

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 set

- Supply Capability:

- 5000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

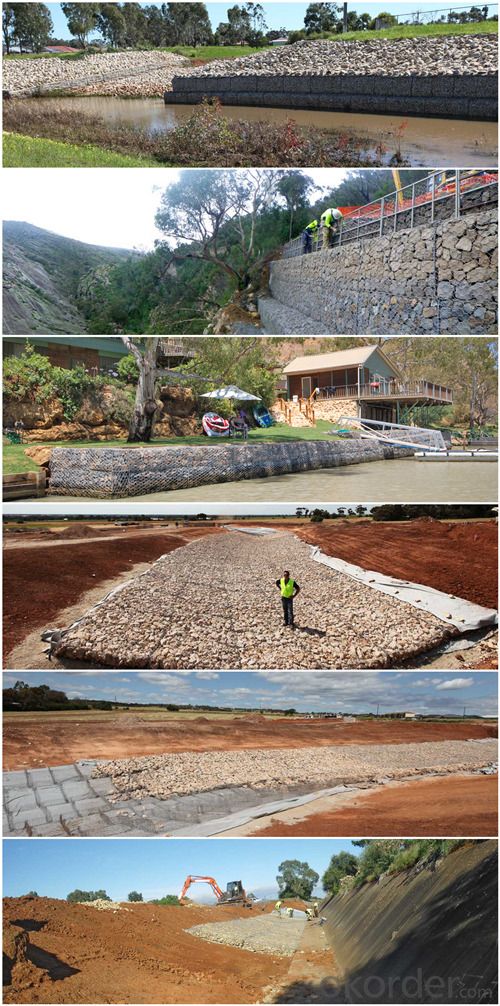

Gabion Box-a double-twisted wire mesh container of variable sizes, uniformly partitioned into internal cells, interconnected with other similar units, and filled with stone at the project site to form flexible, permeable, monolithic structures such as retaining walls, sea wall, channel linings, revetments, and weirs for erosion control projects.

Gabion Mattress-a double-twisted wire mesh container uniformly partitioned into internal cells with relatively small height in relation to other dimensions, having smaller mesh openings than the mesh used for gabions; revet mattresses are generally used for riverbank protection and channel linings.

| Table 1-Sizes for Gabion Box and Gabion Mattress | |||

| L (m) | W (m) | H (m) | # of Cells |

| 2 | 1 | 1 | 2 |

| 3 | 1 | 1 | 3 |

| 4 | 1 | 1 | 4 |

| 2 | 1 | 0.5 | 2 |

| 3 | 1 | 0.5 | 3 |

| 4 | 2 | 0.3 | 4 |

| 6 | 2 | 0.3 | 6 |

| Table 2-Standard Mesh Wire | |||

| Mesh Type | D (mm) | Mesh Tolerance | Mesh Wire (mm) |

| 8x10 | 83 | ±10% | 2.70, 3.00mm |

| 6x8 | 64 | ±10% | 2.20mm |

| Table 3-Standard Wire Diameters | |||||

| Wire Diameter ø mm | 2.20 | 2.70 | 3.00 | 3.40 | 3.80 |

| Wire Tolerance (±) ø mm | 0.10 | 0.10 | 0.10 | 0.10 | 0.10 |

| Min. Qty of Zinc gr/m2 | 214 | 244 | 259 | 259 | 275 |

Double-twisted wire gabions and gabion mattresses are classified according to coating, as follows:

Style 1, consists of double-twisted wire mesh made from wire which is zinc coated before being double-twisted into mesh. Fasteners, lacing wire, and stiffeners are produced from zinc-coated wire.

Style 2, consists of double-twisted wire mesh made from wire which is coated with Zn-5A1-MM before being double-twisted into mesh. Fasteners, lacing wire, and stiffeners are also produced from Zn-5A1-MM coated wire.

Style 3, consists of double-twisted mesh, lacing wire, and stiffeners as Style 1 & 2 and overcoated with PVC. Fasteners shall be of stainless steel wire.

Gabions Production Process:

Case Study of Gabions and Gabion Mattresses:

- Q:Screen printing and screen printing plate on the photosensitive material What are the requirements

- Printing equipment is simple, the operation will be printed, the plate is simple and the low cost of adaptability strong Chinese printing applications wide range of prints: color oil painting,

- Q:Is the screen printing the best way? And other printing methods than it?

- Screen printing is the most adaptable in all printing methods. Ink layer thickest, good hiding power, the best durability, full of bright graphics, other printing methods can not be replaced. Generally used for outdoor advertising, transfer flower paper, electronic lines, glass cloth and other special industries

- Q:How to make screen printing layout smooth

- You use the water-based screen version, or oily screen version. Oily general mesh is more dense. Sensitive plastic easy to have static electricity. So the glue can not play too thick. The choice of sensitive adhesive is also important,

- Q:How to clean the screen plate

- Reset, in order to achieve the next work process to facilitate the operation of personnel cleaning wire mesh, a substantial increase in production efficiency, which due to cleaning the liquid can be used in the machine to achieve recycling,

- Q:Screen printing, how to choose the screen

- You have to choose according to different moments, printing different products, imports a little better

- Q:What are the reasons for the hair making of the screen plate?

- Exposure time is the most important, lack of time, after the version of the mucus to stay in the screen, affecting the printing edge, a long time, it is not easy to open the screen, it will be printed edge defects caused by burr.

- Q:The difference between screen printing characteristics

- But also in the ultra-small, ultra-high precision items on the printing, and can also be printed on the surface or spherical, this printing method has great flexibility and wide applicability.

- Q:Screen printing has several characteristics

- Which forms an image or a text, and the transcript is printed as the easiest stencil, starting at the end of the 19th century. This printing is done on a specially made stencil, made of a typewriter or a pencil,

- Q:Screen printing and other printing methods of the difference

- Ink variety, can print a variety of special effects, three-dimensional sense of strong. The printing method is infinitely changing.

- Q:Screen printing ink firmness problem

- If it is PVC tablecloth, you can try to corona the first surface of the printing process, so that the surface tension higher (recommended to 55 - 60 dyne), and then see if there is improvement.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Galvanized Gabion Box for Civil Engineering 2mx1mx1m

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 set

- Supply Capability:

- 5000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords