Galvanized Cuplock System Scaffolding|Scaffolding Cuplock System CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details of Galvanized Cuplock System Scaffolding|Scaffolding Cuplock System

Type: Heavy Section Steel

Forming: Welding Products

Standard:

Member:

Trademark:

Connection Form:

Carbon Structural Steel:

Residential Wall Structure:

Type of Steel For Building Structure:

Bs1139, En74 Standard:

Export Markets:

Descriptions of Galvanized Cuplock System Scaffolding|Scaffolding Cuplock System

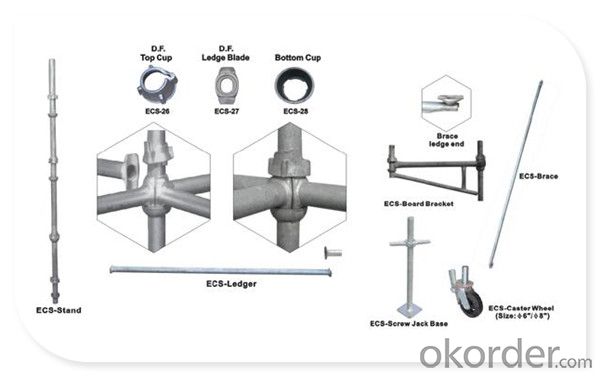

Cuplock is a kind of multi-purpose and versatile modular system scaffolding, suitable for access and formwork support in all types of construction of building & civil engineering projects, offshore projects, etc. This complete galvanized Cuplock system is probably the fastest and most widely preferred scaffolding system. It has flexible erection as straight, curved or circular configuration for both access and support purposes.

Futures of Galvanized Cuplock System Scaffolding|Scaffolding Cuplock System

Multi-functional-with the universal joint and fully interchangeable components, the cuplock system can be used in most construction projects for both formwork and access. It is very versatile and diverse. Use in the shipping industries, oil and gas and aviation industries.

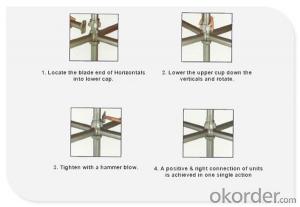

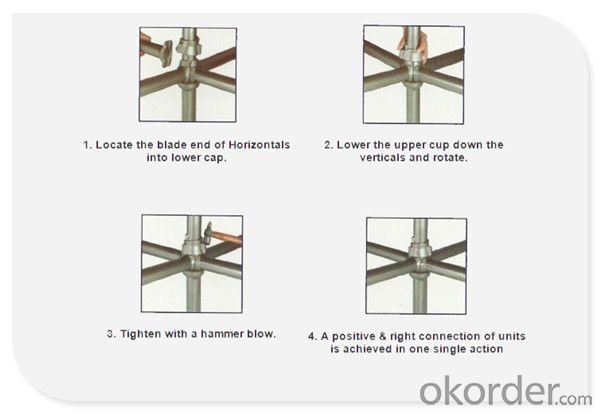

Versatile-Verticals are assembled with horizontals and diagonals using secure fixed cup connections. Its versatility has a distinct advantage to conventional scaffolding methods. A positive & ridged connection of four units is achieved in one single action. The cupock system is very cost effective and can be erected safely and quickly.

Time saving-cuplock scaffold is the solution for temporary structures Performance stages. Small teams can erect it safely and quickly.

Economical-Easily assembled system scaffold saves time and labor costs.

Durable-All components are hot dip galvanized and manufactures to international standard.

Easily Stored-Individual pipe elements can be packed in bundles for easy storage and transportation. For returns, material can be packed in steel racks.

The Main Components of Galvanized Cuplock System Scaffolding|Scaffolding Cuplock System

Verticals

Description

Material

kg/pc

Article No.

9'10" Vertical 3.00m

Q345 φ48.3×3.2

16.90

SC1001 3000

8'2" Vertical 2.50m

Q345 φ48.3×3.2

14.20

SC1001 2500

6'6" Vertical 2.00m

Q345 φ48.3×3.2

11.60

SC1001 2000

4'11" Vertical 1.50m

Q345 φ48.3×3.2

8.90

SC1001 1500

3'3" Vertical 1.00m

Q345 φ48.3×3.2

6.20

SC1001 1000

1' Vertical 0.50m

Q345 φ48.3×3.2

3.50

SC1001 0500

Horizontals

Description

Material

kg/pc

Article No.

10'0" Horizontal 3.05m

Q345 φ48.3×3.2

11.80

SC1002 3048

9'0" Horizontal 2.74m

Q345 φ48.3×3.2

10.70

SC1002 2743

8'2" Horizontal 2.50m

Q345 φ48.3×3.2

9.80

SC1002 2500

7'0" Horizontal 2.13m

Q345 φ48.3×3.2

8.40

SC1002 2133

6'6" Horizontal 2.00m

Q345 φ48.3×3.2

7.90

SC1002 2000

6'0" Horizontal 1.83m

Q345 φ48.3×3.2

7.20

SC1002 1828

5'11" Horizontal 1.80m

Q345 φ48.3×3.2

7.10

SC1002 1800

5'0" Horizontal 1.52m

Q345 φ48.3×3.2

6.10

SC1002 1524

4'11" Horizontal 1.50m

Q345 φ48.3×3.2

6.00

SC1002 1500

4'1" Horizontal 1.25m

Q345 φ48.3×3.2

5.00

SC1002 1250

4'0" Horizontal 1.22m

Q345 φ48.3×3.2

4.90

SC1002 1219

3'6" Horizontal 1.07m

Q345 φ48.3×3.2

4.30

SC1002 1067

3'3" Horizontal 1.00m

Q345 φ48.3×3.2

4.10

SC1002 1000

3'0" Horizontal 0.91m

Q345 φ48.3×3.2

3.80

SC1002 0914

2'11" Horizontal 0.90m

Q345 φ48.3×3.2

3.70

SC1002 0900

8'0" Horizontal 2.44m

Q345 φ48.3×3.2

9.50

SC1002 2438

1'10" Horizontal 0.57m

Q345 φ48.3×3.2

2.40

SC1002 0600

FAQ

1. What is considerations of Scaffolding installation?

There must be a fire protection measures and specialist care, safety personnel patrol inspection when electricity, gas welding work on the scaffold,

(1) scaffold frontage hurtful to prevent falling objects protection is required.

(2) During take down the scaffolding, fencing and warning signs should be set up on the ground, prohibit others person besides the operator

2.What are the certifications of your products?

Certified by SGS, BS1139, EN74, Local Test Report.

3. How long is the warranty period for your product?

Our products warranty is 2 years.

- Q:Said chrysanthemum disc scaffolding system, disc scaffolding system, wheel type scaffolding system, buckle scaffold, layher frame

- PoleName specification A (mm) B (mm) theoretical weight (kg)Riser LG-60 6004LG-120 12007.41LG-180 180010.67LG-240 240014.02LG-300 300017.31

- Q:Which God can tell me what is required, how to get ah?

- Whether the site is to use their own hand foot disc accessories, accessories or disc scaffolding rental, before use should be carried out preliminary calculation, see how many accessories, the same buildings of different height should be calculated separately, is used to prevent waste of transportation. To achieve cost savings must be accurate calculation. You can go to the mall extension carefully and look at the product deformation, distortion, rust, if any of the above parts, should immediately terminate the use of such products can not be put into construction and.

- Q:would a scaffold piercing look gay on a guy?

- i guess it depends on what you look like.

- Q:In the construction of steel pipe scaffolding steel pipe and steel stamping fastener usage ratio is how much?

- There are a lot of people do not know the construction of steel pipe scaffolding and steel plate and the proportion of the amount of stamping fastener is much, then let the people tell you the problem

- Q:Was thinking of getting one. How much do they cost?

- Only a professional piercer can decide if your ear can handle and industrial piercing. Consultations are free and I highly recommend booking one before you get the piercing. Mine was $70, but my regular piercer does them for $50. It just depends on what shop you go to.

- Q:So I had a scaffold/industrial done about 10 weeks ago, and its been infected at the top hole only for about 3/4 weeks. It has like a little bubble near the hole and sometimes its filled with pus a little bit and sometimes its not. Well I went the doctors about 2 weeks ago and he prescribed me a weeks worth of antibiotics as well as anti-septic cream. So I took the pills for a week and it was clearing up, I was also applying the cream twice a day. But then yesterday I noticed the lump has gotten a little bit bigger. I don't know what to do, should I take it out? But I really don't want to. And plus the doc said to wait up to 3 weeks and if nothings changed to go back and take it out. If I continue to use the cream, will it eventually go? Thanks :)

- have a piercer look at it.

- Q:Specification for construction steel pipe scaffolding and construction safety rules?

- 2, operating conditionsAccording to the engineering characteristics and construction requirements of the scaffolding erection scheme.The shelf position has to clean up the site.On the soft soil foundation has been hardening.

- Q:i am getting my industrial (scaffold) pierced on one ear and i want my cartilage on the other ear, how long do i have to wait between them? What are pros and cons for industrial (scaffold)? what are risks and stuff and how much is it? i want to get it so any information or anything i should know would be great thanks especially for industrial:)

- i heard from people after a year an industrial still hurts and they usually have to take them out

- Q:1.How does Pearl react when Dimmesdale calls Hester and herself to mount the scaffold with him?

- The answer can be found in the novel The Scarlet Letter by Nathaniel Hawthorne. Read that and you'll have the answer!

- Q:I've had my scaffolding piercing for about a week now and when cleaning i've just dabbed the hydrogen peroxide and salt water around my ear. However i read that i should be rotating it when cleaning it. Should i rotate it after only a week?

- you dont need to rotate a scaffolding piercing because its in such a place that it will rotate on its own throughout the day/night

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Galvanized Cuplock System Scaffolding|Scaffolding Cuplock System CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords