Galvanized Corrugated Steel Sheet in High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot-dip Zinc Coating Steel Building Roof Walls

1.Structure of Hot-Dip Galvanized Steel Sheet Description:

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hotdip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial applications. Production of cold formed corrugated sheets and profiles for roofing, cladding, decking, tiles, sandwich walls, rainwater protective systems, air conditioning duct as well as electrical appliances and engineering.

2.Main Features of the Hot-Dip Galvanized Steel Sheet:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent anticorrosive property

• High strength

• Good formability

• Good visual effect

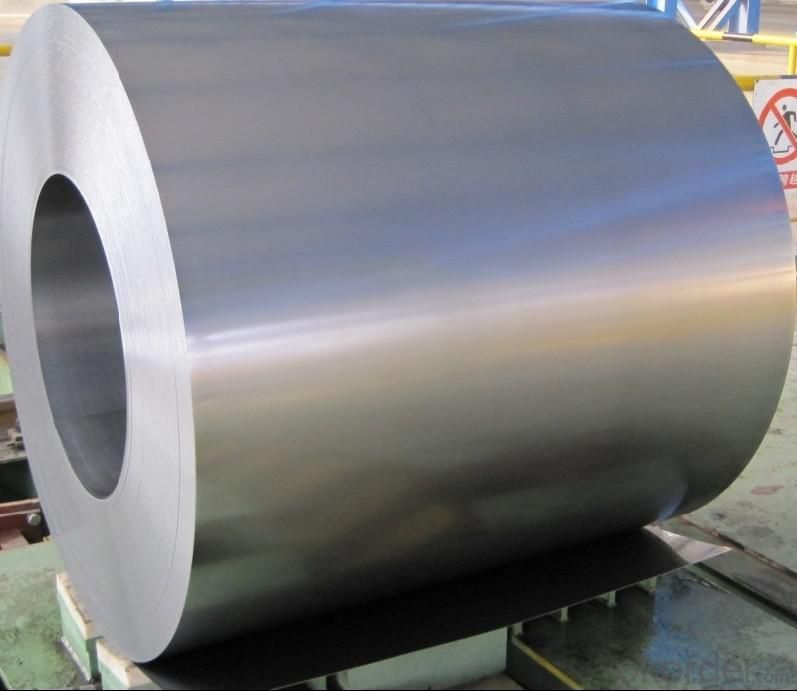

3.Hot-Dip Galvanized Steel Sheet Images

4.Hot-Dip Galvanized Steel Sheet Specification

Standard: ASTM, JIS,EN

Grade: CS, DX51D+Z,SGCC, SS 230~550,S220GD+Z~S550GD+Z, SGC340~SGC570

Thickness: 0.1mm~5mm

Width: max 2000mm

Coil weight:3-12 MT

Coil ID:508/610mm

Surface structure: zero spangle, regular spangle or minimum spangle

Surface treatment: Chromate treatment, Oiled/dry, skinpassed/non-skinpassed

Packing: Standard seaworthy export package

Technology test results:

| Processability | Yield strength | Elongation % | Elongation % | 180°cold-bending |

| Common PV | - | 270-500 | - | d=0,intact,no zinc removal |

| Mechanical interlocking JY | - | 270-500 | - | d=0,intact,no zinc removal |

| Structure JG | >=240 | >=370 | >=18 | d=0,intact,no zinc removal |

| Deep drawn SC | - | 270-380 | >=30 | d=0,intact,no zinc removal |

| EDDQ SC | - | 270-380 | >=30 | d=0,intact,no zinc removal |

5.FAQ of Hot-Dip Galvanized Steel Sheet

We have organized several common questions for our clients,may help you sincerely:

1.How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-30 days, but the shipment will depend on the vessel situation.

- Q:How are steel sheets protected during storage in warehouse facilities?

- Steel sheets are protected during storage in warehouse facilities through various measures such as applying protective coatings, using moisture-resistant packaging, implementing proper stacking and handling techniques, and maintaining controlled temperature and humidity levels to prevent corrosion and damage.

- Q:Are steel sheets suitable for railway infrastructure?

- Railway infrastructure can benefit greatly from the use of steel sheets. Steel is a popular choice for constructing railway infrastructure because it is strong, durable, and versatile. One of the main advantages of steel sheets in railway infrastructure is their high strength-to-weight ratio. Steel is exceptionally strong, allowing it to handle heavy loads and provide long-lasting support to railway tracks, bridges, and other structures. This strength is crucial for the safety and stability of the railway system, especially when dealing with the weight and impact forces exerted by trains. Furthermore, steel sheets offer excellent durability and resistance to wear and tear. Railway infrastructure is constantly exposed to stress, including vibrations, impacts, and extreme weather conditions. Steel's inherent properties make it highly resilient to these factors, reducing the need for frequent repairs and maintenance. This durability leads to significant cost savings in the long run, as steel structures have a longer lifespan compared to other materials. In addition, steel sheets are highly versatile and can be easily shaped and sized to meet specific railway infrastructure requirements. This flexibility allows for the efficient construction of rails, sleepers, bridges, and other components necessary for a functional and safe railway system. Steel's adaptability also enables easy modifications and expansions to the infrastructure as needed, ensuring compatibility with changing transportation needs. To summarize, steel sheets are an excellent choice for railway infrastructure due to their strength, durability, and versatility. Their high strength-to-weight ratio, resistance to wear and tear, and ease of fabrication make them ideal for constructing and maintaining railway tracks, bridges, and other structures. The use of steel in railway infrastructure guarantees the safety, efficiency, and longevity of the railway system.

- Q:What is the standard size of steel sheets?

- The standard size of steel sheets can vary depending on the specific application and industry requirements. However, common standard sizes for steel sheets typically range from 4 feet by 8 feet to 6 feet by 20 feet, with thicknesses ranging from 0.15 inches to 0.5 inches.

- Q:Are steel sheets resistant to warping or bending?

- Steel sheets are generally known for their high tensile strength and stiffness, making them resistant to warping or bending. They are highly durable and can withstand heavy loads without deforming. However, it is important to consider that the thickness and quality of the steel sheet can affect its resistance to warping or bending. Thicker steel sheets tend to be more resistant compared to thinner ones. Additionally, factors like temperature changes and improper handling or installation can also impact the ability of steel sheets to resist warping or bending. Despite these factors, steel sheets are widely used in various industries due to their exceptional resistance to warping or bending.

- Q:Are steel sheets resistant to staining?

- Yes, steel sheets are highly resistant to staining due to their non-porous surface and protective coating, making them a reliable option for applications where stains are a concern.

- Q:Can steel sheets be used for elevator panels or interiors?

- Yes, steel sheets can be used for elevator panels or interiors. Steel is a durable and versatile material that can provide a sleek and modern look to elevator designs. It is commonly used in the construction of elevator interiors due to its strength, resistance to wear and tear, and ease of maintenance.

- Q:How do you prevent scratches or dents on steel sheets?

- One way to prevent scratches or dents on steel sheets is by handling them with care and using protective measures, such as wearing gloves and using padding or protective covers during transportation or storage. Additionally, ensuring a clean and debris-free work area and avoiding contact with sharp or rough surfaces can help minimize the risk of scratches or dents on steel sheets.

- Q:Are the steel sheets suitable for food-grade applications?

- Yes, steel sheets can be suitable for food-grade applications. Stainless steel in particular is commonly used in the food industry due to its excellent corrosion resistance, durability, and ease of cleaning. It is non-reactive and does not release any harmful substances into food, making it a safe choice for food storage, processing, and transportation. Additionally, stainless steel is resistant to high temperatures and can withstand rigorous cleaning and sanitization processes, making it ideal for use in food-grade applications. However, it is important to ensure that the steel sheets meet the necessary food-grade standards and regulations before using them in any food-related setting.

- Q:Can steel sheets be used for electrical grounding purposes?

- Certainly! Electrical grounding purposes can indeed utilize steel sheets. Steel, being an excellent conductor of electricity, is well-suited for grounding applications. By appropriately linking them to an electrical system, steel sheets can offer an efficient route for the discharge of electrical charges and the avoidance of electrical shock risks. Nevertheless, it is crucial to guarantee that the steel sheets are suitably bonded and connected to the grounding system to establish a path of low resistance for fault currents. Furthermore, factors like the thickness and surface area of the steel sheets should be taken into account to ensure they satisfy the criteria for effective grounding.

- Q:How are steel sheets protected during storage in humid environments?

- Steel sheets are protected during storage in humid environments by applying a protective coating, such as a layer of oil or zinc, which acts as a barrier against moisture and prevents corrosion. Additionally, proper packaging and storage techniques, such as using moisture-absorbing materials and maintaining appropriate temperature and ventilation, are employed to minimize the exposure of steel sheets to humidity.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Galvanized Corrugated Steel Sheet in High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords