Galvanized Corrugated Steel Sheet in High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot-dip Zinc Coating Steel Building Roof Walls

1.Structure of Hot-Dip GI/GL Steel Sheet Description:

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial applications. Production of cold formed corrugated sheets and profiles for roofing, cladding, decking, tiles, sandwich walls, rainwater protective systems, air conditioning duct as well as electrical appliances and engineering.

2.Main Features of the Hot-Dip GI/GL Steel Sheet:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent anticorrosive property

• High strength

• Good formability

• Good visual effect

3.Hot-Dip GI/GL Steel Sheet Images:

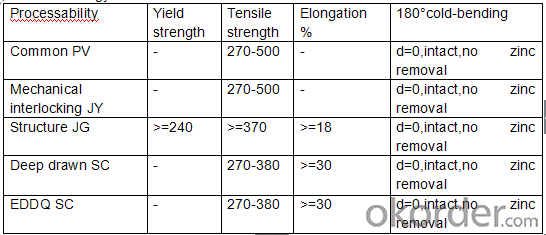

4.Hot-Dip GI/GL Steel Sheet Specification:

Standard: ASTM, JIS,EN

Grade: CS, DX51D+Z,SGCC, SS 230~550,S220GD+Z~S550GD+Z, SGC340~SGC570

Thickness: 0.1mm~5mm

Width: max 2000mm

Coil weight:3-12 MT

Coil ID:508/610mm

Surface structure: zero spangle, regular spangle or minimum spangle

Surface treatment: Chromate treatment, Oiled/dry, skinpassed/non-skinpassed

Packing: Standard seaworthy export package

Technology test results:

5.FAQ of Hot-Dip GI/GL Steel Sheet:

We have organized several common questions for our clients,may help you sincerely:

1.How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-30 days, but the shipment will depend on the vessel situation.

- Q:How do steel sheets handle thermal insulation?

- Steel sheets are not good thermal insulators as they conduct heat very well.

- Q:Can the steel sheets be easily formed into decorative panels?

- Indeed, decorative panels can be effortlessly crafted from steel sheets. Steel, being a flexible material, can be molded and shaped into diverse forms, including decorative panels. By utilizing appropriate tools and methodologies, steel sheets can be skillfully cut, bent, and manipulated to produce intricate and distinctive designs. Furthermore, steel possesses exceptional durability and longevity, rendering it a perfect choice for decorative panels that necessitate both visual allure and structural soundness. Whether it is for architectural objectives, interior design endeavors, or artistic installations, steel sheets can be readily transformed into visually captivating and functionally efficient decorative panels.

- Q:Can steel sheets be used for water storage tanks?

- Yes, steel sheets can be used for water storage tanks. Steel is a durable and strong material that is commonly used in the construction of water storage tanks. It is resistant to corrosion and can withstand harsh weather conditions, making it an ideal choice for long-term water storage.

- Q:What are the different profile options available for steel sheets?

- There are several different profile options available for steel sheets, each serving different purposes and offering unique benefits. Some of the most common profile options include: 1. Plain Sheet: This is the simplest and most basic profile option, with a flat surface and no additional features. It is commonly used for general purposes where aesthetics are not a priority. 2. Corrugated Sheet: Corrugated steel sheets have a series of parallel ridges and grooves, creating a wavy pattern. This profile provides extra strength and rigidity, making it ideal for roofing, cladding, and fencing applications. The ridges also enhance water shedding, preventing water accumulation on the surface. 3. Ribbed Sheet: Ribbed steel sheets have a series of raised parallel ridges or ribs running along the length of the sheet. This profile offers improved strength and load-bearing capacity, making it suitable for applications that require structural integrity, such as mezzanine floors, decking, and industrial flooring. 4. Perforated Sheet: Perforated steel sheets have a pattern of holes punched into them, allowing for ventilation, light transmission, and drainage. This profile is commonly used in architectural designs, façades, acoustics, and filtration systems. 5. Tread Plate: Tread plates have a raised pattern of lines or diamonds embossed on the surface. This profile provides extra grip and slip resistance, making it ideal for industrial flooring, stairs, ramps, and walkways. 6. Expanded Metal: Expanded metal sheets are created by cutting and stretching a flat sheet, resulting in a pattern of diamond-shaped openings. This profile offers excellent ventilation, visibility, and security, making it suitable for applications such as grilles, screens, fences, and enclosures. 7. Lipped Sheet: Lipped steel sheets have an edge or lip bent at a 90-degree angle along one or more sides. This profile provides added strength and stiffness, making it commonly used for framing, shelving, and edge protection. These are just a few examples of the different profile options available for steel sheets. The choice of profile depends on the specific requirements of the application, such as strength, durability, aesthetics, and functionality.

- Q:Are steel sheets suitable for architectural roofing?

- Architectural roofing can benefit greatly from the use of steel sheets. This material is known for its exceptional durability and longevity, making it an ideal option for such applications. Steel sheets possess impressive strength, enabling them to withstand even the harshest weather conditions like heavy rain, snow, and strong winds. They also offer an additional layer of safety as they are resistant to fire. Another advantage is that steel sheets are lightweight, which makes them easier to install and reduces the burden on the structure. Additionally, architects can choose from a wide range of colors and finishes to achieve the desired aesthetic appearance for the building. In summary, steel sheets are an excellent choice for architectural roofing due to their numerous advantages, making them suitable for both residential and commercial projects.

- Q:How can steel sheets be protected from corrosion?

- Steel sheets can be protected from corrosion through various methods such as applying protective coatings like paint or galvanization, using corrosion inhibitors, implementing cathodic protection, or utilizing stainless steel with inherent corrosion resistance.

- Q:Are steel sheets suitable for flooring applications?

- Yes, steel sheets are suitable for flooring applications. Steel sheets are known for their durability, strength, and resistance to wear and tear. They can provide a stable and long-lasting flooring option in various settings, including industrial, commercial, and even residential spaces. Additionally, steel sheets can be easily customized to meet specific design requirements, making them versatile for flooring applications.

- Q:Are steel sheets suitable for automotive chassis?

- Automotive chassis can indeed be made using steel sheets. Steel is a favored option for constructing automotive chassis because of its robustness, durability, and affordability. It provides exceptional structural integrity and can endure the various forces and strains encountered by a vehicle during operation. Steel sheets also possess commendable resistance against impacts, vibrations, and corrosion, which renders them highly suitable for utilization in automotive chassis. Furthermore, steel is a readily accessible material that can be easily shaped, welded, and molded into diverse forms and sizes, thus allowing for flexibility in design and manufacturing procedures. In summary, steel sheets are a trustworthy and extensively employed material in the automotive sector when it comes to fabricating chassis that fulfill the necessary safety, performance, and longevity criteria.

- Q:Can steel sheets be used in renewable energy applications?

- Yes, steel sheets can be used in renewable energy applications. Steel is a versatile and durable material that can be used in various components of renewable energy systems such as solar panels, wind turbines, and hydropower facilities. It is commonly used in the construction of support structures, frames, and enclosures due to its strength, corrosion resistance, and cost-effectiveness.

- Q:Can steel sheets be used for fencing applications?

- Yes, steel sheets can be used for fencing applications. Steel sheets are commonly used for fencing due to their durability, strength, and resistance to harsh weather conditions. They provide a sturdy and secure barrier, making them suitable for various fencing applications such as residential, commercial, industrial, and agricultural purposes.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Galvanized Corrugated Steel Sheet in High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords