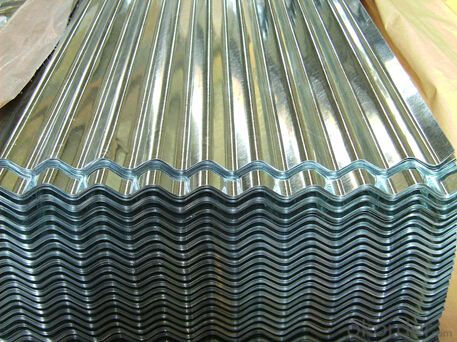

galvanized corrugated steel sheet high quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Hot-Dip Galvanized Steel Roof Description:

Hot-dip galvanized steel roof are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial application.

2.Main Features of the Hot-Dip Galvanized Steel Roof:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

3.Hot-Dip Galvanized Steel Roof Images

4.Hot-Dip Galvanized Steel Roof Specification

Material: Galvanized Sheet

Width: 650/800/890/900

Length: 1500/1800/2000/2400/3005/3600 or customized

Thickness: 0.2-2.0

Surface Treatment: Hot dipped/Bended

Application: warehouse; shelter; Commercial facilities; industrial facilities

5.FAQ of Hot-Dip Galvanized Steel Roof

Which payment term we can do?

L/C at sight or T/T.

What’s the basic material of this product?

Galvanized/Aluzinc Steel

- Q:Are steel sheets suitable for fire-resistant applications?

- Steel sheets are indeed appropriate for applications that require resistance to fire. Steel has gained a reputation for its exceptional fire resistance properties, primarily because of its high melting point and its reluctance to ignite or facilitate the spread of fire. Steel sheets can be employed in an array of fire-resistant applications, including fire doors, fire-rated walls, and fireproof enclosures. Moreover, steel sheets can be combined with other fire-resistant materials, like fire-resistant coatings or insulation, to augment their fire resistance even further. In general, steel sheets are a dependable option for fire-resistant applications owing to their robustness, potency, and capacity to endure high temperatures.

- Q:What are the different bending radius options for steel sheets?

- The bending radius options for steel sheets can vary depending on the thickness and type of steel being used. Generally, the bending radius for steel sheets ranges from 0.5 to 2 times the thickness of the sheet. For thinner sheets, such as those with a thickness of 0.5mm to 2mm, a bending radius of 0.5 to 1 times the sheet thickness is typically recommended. This allows for a tighter bend without risking cracking or deformation of the steel. For thicker sheets, such as those with a thickness of 2mm to 6mm, a bending radius of 1 to 1.5 times the sheet thickness is commonly used. This ensures that the steel retains its structural integrity and prevents any excessive stress or strain during the bending process. For even thicker sheets, typically above 6mm, a bending radius of 1.5 to 2 times the sheet thickness is often required. This larger bending radius helps to avoid any potential damage or distortion to the steel, ensuring a successful bending operation. It is important to note that these bending radius options are general guidelines and may vary depending on the specific steel grade, composition, and intended application. It is always recommended to consult the manufacturer's recommendations or seek expert advice when determining the appropriate bending radius for steel sheets.

- Q:What is the average wind load capacity of steel sheets?

- The average wind load capacity of steel sheets can vary depending on various factors such as sheet thickness, size, shape, and the specific steel material used. It is typically determined by conducting engineering calculations and considering local building codes and standards. Therefore, it is not possible to provide a specific average wind load capacity without knowing the specific details of the steel sheets in question.

- Q:What are the common surface treatments for steel sheets?

- The common surface treatments for steel sheets include galvanizing, powder coating, painting, and plating.

- Q:What is the hardness of steel sheets?

- The hardness of steel sheets can vary depending on the specific type and grade of steel, but generally, steel sheets have a high level of hardness ranging from 30 to 60 on the Rockwell C scale.

- Q:Are steel sheets susceptible to rusting?

- Steel sheets can indeed be prone to rusting. The composition of steel mainly consists of iron, a metal that has a natural tendency to react with oxygen when in contact with moisture, resulting in the formation of iron oxide, commonly referred to as rust. Consequently, when steel sheets come into contact with water or moisture, rusting can occur gradually. Nevertheless, there exist techniques to hinder or decelerate the rusting process, including the application of protective coatings or the utilization of stainless steel. The latter contains elements like chromium that offer supplementary protection against corrosion.

- Q:How are steel sheets tested for hardness?

- Various methods are employed to test the hardness of steel sheets, with one of the most commonly used being the Rockwell hardness test. In this test, a known force is applied to the steel sheet's surface using a small indenter, typically a diamond or a hardened steel ball. The resulting depth of penetration is then measured and standardized to determine the hardness value. Another method utilized is the Brinell hardness test, which involves pressing a hardened steel ball into the steel sheet's surface under a specific load. The diameter of the resulting indentation is measured and used to calculate the hardness value. Furthermore, the Vickers hardness test employs a pyramid-shaped diamond indenter. Similar to the Rockwell test, this method measures the indentation produced, but instead of focusing on the depth of penetration, it determines the hardness value by measuring the diagonal length of the indentation. These hardness tests yield significant insights into the mechanical properties of steel sheets, including their resistance to deformation and wear. By ensuring that the steel sheets meet the required specifications, the test results enable their use in various applications where hardness plays a critical role.

- Q:Can steel sheets be used for roofing purposes?

- Yes, steel sheets can be used for roofing purposes. Steel is a durable and long-lasting material that is resistant to corrosion, making it an excellent choice for roofing. Steel sheets provide strength and stability to the roof, protecting the building from various weather conditions. Additionally, steel roofs are low maintenance and can be energy-efficient if properly insulated.

- Q:Can the steel sheets be easily drilled for fastening purposes?

- Yes, steel sheets can be easily drilled for fastening purposes.

- Q:What are the insulation properties of steel sheets?

- Steel sheets have relatively poor insulation properties compared to other materials commonly used for insulation, such as fiberglass or foam. This is because steel is a good conductor of heat and electricity. It has high thermal conductivity, meaning that it can easily transfer heat from one side to the other. Therefore, steel sheets are not effective in preventing heat transfer and are not typically used as insulation materials on their own. However, steel sheets can still provide some insulation benefits when used in combination with other insulating materials. For instance, steel sheets can be used as a protective layer or cladding to enhance the durability and fire resistance of insulation systems. They can also be used as a radiant barrier, reflecting heat away from the building and reducing heat gain in warm climates. In summary, while steel sheets themselves do not have great insulation properties, they can play a role in enhancing the overall insulation performance when combined with other insulating materials or used in specific applications like radiant barriers.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

galvanized corrugated steel sheet high quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords