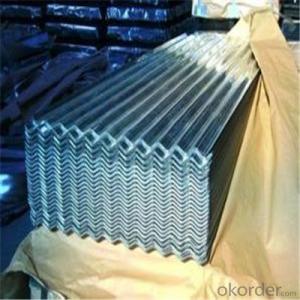

Galvanized Corrugated Steel Sheet for Roofing Type Galvanized steel Plain Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 40 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Description of Corrugated Iron Sheet:

Standard: GB/T 12754-2006;ASTM A 755;EN 10169;JIS G 3312;AISI;BS;DIN Grade: SGCC,SGCH,G550,DX51D,DX52D,DX53D

Specifications of Corrugated Iron Sheet:

| Product Name | Wave Tile |

| Standard: | GB , ASTM , JIS etc |

| Raw Material | GI , GL , PPGI , PPGL |

| Thickness | 0.15mm-0.6mm |

| Width | 750mm-1000mm(BC)/665-920mm(AC) |

| Length | 4000mm(Max) |

| Coating | AZ40-AZ160g , Z50-Z140g |

| Temper | Full hard , half hard , annealed |

| Spangle | Regular , Minimized , Big spangle |

| Pallet Weight: | 2-4mt |

| Material | SGCH , SGLCH , SGCC |

| Payment: | Trade Assurance OF Alibaba ,T/T, L/C at sight |

| MOQ: | 20 ton each size, 1x20'ft per delivery |

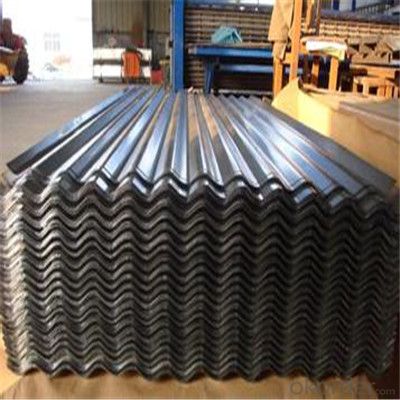

Features of Corrugated Iron Sheet:

various roofs or walls referring to the large size factory buildings, storages, exhibition halls, gymnasiums etc.

Images of Corrugated Iron Sheet:

FAQ:

1. What's the Delivery port?

The main ports are Qingdao and Tianjin, we also can deliver to other ports to meet your requirements

2. How long is the lead time?

Delivery time: 45 days after order confirmed.

3. What payment term do you accept?

Payment: T/T or L/C at sight.

- Q:Can steel sheets be used in the manufacturing of appliances?

- Appliances can indeed incorporate steel sheets into their manufacturing process. The manufacturing industry heavily relies on steel due to its exceptional qualities of strength, durability, and versatility. Steel sheets can be manipulated to fit various sizes and designs, catering to the unique specifications of different appliances. Furthermore, steel exhibits resistance against corrosion, rendering it suitable for appliances that may encounter water or other liquids. Additionally, steel serves as an exceptional conductor of heat, proving advantageous for appliances that necessitate efficient heat transfer. Consequently, steel sheets are widely employed in the fabrication of appliances, including refrigerators, ovens, dishwashers, washing machines, and numerous others.

- Q:Can steel sheets be used for modular furniture?

- Yes, steel sheets can indeed be used for modular furniture. Steel is a durable and versatile material that can be easily shaped and formed into various sizes and designs. It provides strength and stability to furniture structures, making it suitable for modular furniture applications. Additionally, steel sheets can be finished with different coatings or paints to enhance their aesthetic appeal and protect against corrosion.

- Q:What is the fatigue strength of steel sheets?

- The fatigue strength of steel sheets refers to the maximum stress level that the sheets can sustain for a certain number of cycles without failing due to fatigue.

- Q:Stainless steel plate and steel welding

- Can be welded, stainless steel electrodes must be used, but also more than you use the stainless steel plate material, a higher level of welding rod! Before welding, the steel is to be polished to rust. Sub arc welding can also be used

- Q:What is the difference between a brushed and etched steel sheet?

- A brushed steel sheet and an etched steel sheet are both types of metal sheets that have undergone different surface treatments, resulting in distinct appearances and characteristics. A brushed steel sheet is created by brushing the surface of the steel with an abrasive material, usually a wire brush or sandpaper. This process creates a textured pattern of fine lines or scratches on the surface of the steel. The purpose of brushing is primarily to enhance the aesthetic appeal of the steel sheet, giving it a satin-like finish. Brushed steel is often used in architectural and design applications where a sleek and contemporary look is desired. It is also commonly used in kitchen appliances and automotive parts due to its resistance to fingerprints and scratches. On the other hand, an etched steel sheet is produced by a chemical or acid etching process. This involves applying an acid-resistant material, such as a resist or a stencil, onto the steel surface and then exposing it to an acid solution. The acid eats away at the exposed parts of the steel, creating a pattern or design. Etching is used to achieve intricate and detailed designs on steel sheets, making it popular in industries such as signage, jewelry, and art. The etched patterns can range from simple geometric shapes to elaborate images or text. In summary, the main difference between a brushed and etched steel sheet lies in the method used to achieve their respective surface textures. Brushing results in a consistent pattern of fine lines, creating a satin-like finish for aesthetic purposes. Etching, on the other hand, involves a chemical process that creates detailed and intricate designs on the steel surface.

- Q:Can steel sheets be used for heat exchangers?

- Yes, steel sheets can be used for heat exchangers. Steel is a common material used in heat exchangers due to its excellent thermal conductivity and durability. However, the specific type of steel and its composition may vary depending on the application and desired performance of the heat exchanger.

- Q:What can be painted on galvanized steel sheet?

- Paint matching1. The paint preparation system used for galvanized steel in soaking or humid environment must be alkali resistant and can not be saponified. Therefore, it is advisable to choose epoxy type coating. Best with epoxy zinc yellow primer.2, for exposure in the dry environment of galvanized steel, zinc yellow epoxy primer can be used with acrylic polyurethane topcoat, or intermediate epoxy zinc chromate primer + epoxy micaceous iron oxide + fluorocarbon topcoat with ultra weatherability, long service life of the supporting scheme.In short, surface treatment is very important, considering the durability of galvanized parts, it is recommended to use the above two kinds of matching paint to ensure the normal service life and reduce the cost of intermediate maintenance.

- Q:Can steel sheets be used for interior wall applications?

- Yes, steel sheets can be used for interior wall applications. Steel sheets are strong, durable, and fire-resistant, making them suitable for use in various indoor settings. They can be installed as decorative panels or as a base material for wall cladding systems. Additionally, steel sheets offer benefits such as easy maintenance, excellent sound insulation, and the ability to withstand moisture and humidity.

- Q:Can steel sheets be used for industrial machinery parts?

- Yes, steel sheets can be used for industrial machinery parts. Steel is a commonly used material in the manufacturing industry due to its strength, durability, and versatility. Steel sheets can be fabricated and shaped to meet the specific requirements of machinery parts, making them suitable for various industrial applications.

- Q:How do steel sheets compare to other types of sheet materials?

- Steel sheets are known for their exceptional strength, durability, and resistance to corrosion, making them superior to many other types of sheet materials. Additionally, steel sheets offer excellent thermal conductivity, making them suitable for various applications. However, steel sheets can be heavier and more expensive compared to some other materials, and their susceptibility to rust can be a disadvantage in certain environments.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Galvanized Corrugated Steel Sheet for Roofing Type Galvanized steel Plain Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 40 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords