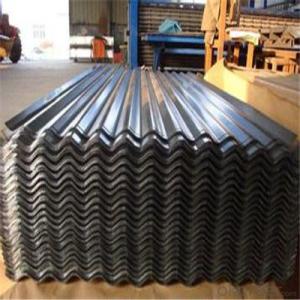

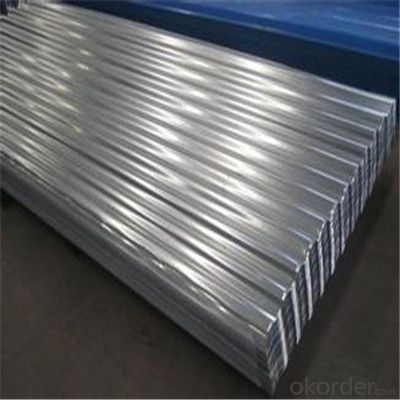

Galvanized Corrugated Iron Sheet for Roofing

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Description of Corrugated Iron Sheet:

1.Grade:SGCC, DX51D+Z, DX52D+Z, etc

2.Application:automotive, Strengthen plate, bearing

Specifications of Corrugated Iron Sheet:

| Product Name | Wave Tile |

| Standard: | GB , ASTM , JIS etc |

| Raw Material | GI , GL , PPGI , PPGL |

| Thickness | 0.15mm-0.6mm |

| Width | 750mm-1000mm(BC)/665-920mm(AC) |

| Length | 4000mm(Max) |

| Coating | AZ40-AZ160g , Z50-Z140g |

| Temper | Full hard , half hard , annealed |

| Spangle | Regular , Minimized , Big spangle |

| Pallet Weight: | 2-4mt |

| Material | SGCH , SGLCH , SGCC |

| Payment: | Trade Assurance OF Alibaba ,T/T, L/C at sight |

| MOQ: | 20 ton each size, 1x20'ft per delivery |

Features of Corrugated Iron Sheet:

Long Lasting

Strong & Light Weight

Better Corrosion Resistance

Better Thermal Efficiency

Aesthetically Pleasing

Images of Corrugated Iron Sheet:

FAQ:

1. What's the Delivery port?

The main ports are Qingdao and Tianjin, we also can deliver to other ports to meet your requirements

2. How long is the lead time?

Delivery time: 45 days after order confirmed.

3. What payment term do you accept?

Payment: T/T or L/C at sight.

- Q:What are the different sheet metal stamping techniques for steel sheets?

- There are several sheet metal stamping techniques for steel sheets, including blanking, piercing, bending, deep drawing, and embossing.

- Q:What is the difference between a galvanized and aluminum steel sheet?

- The main difference between a galvanized steel sheet and an aluminum steel sheet lies in their composition and characteristics. Galvanized steel sheets are made from steel that has been coated with a layer of zinc, which helps to protect it from corrosion. This coating gives galvanized steel sheets a shiny, spangled appearance. On the other hand, aluminum steel sheets are made from aluminum alloy, which is naturally resistant to corrosion. Aluminum steel sheets are typically lighter and more malleable than galvanized steel sheets. Additionally, aluminum steel sheets have a duller, matte appearance compared to the shiny surface of galvanized steel sheets. Overall, the choice between galvanized and aluminum steel sheets depends on factors such as desired aesthetics, strength, corrosion resistance, and cost.

- Q:Are steel sheets resistant to chemical exposure?

- Yes, steel sheets are generally resistant to chemical exposure.

- Q:How do steel sheets perform in extreme weather conditions?

- Steel sheets are highly durable and resistant to extreme weather conditions. They are able to withstand high winds, heavy rain, snow, and even hail. Due to their strength and corrosion-resistant properties, steel sheets provide excellent protection against harsh weather elements, making them a reliable choice for various applications in extreme weather conditions.

- Q:What is the process of applying anti-slip coatings to steel sheets?

- The process of applying anti-slip coatings to steel sheets typically involves several steps. First, the steel sheets are thoroughly cleaned and prepared to ensure proper adhesion of the coating. This may involve removing any dirt, oil, or rust from the surface. Once the surface is clean, a primer or bonding agent is applied to enhance the adhesion of the anti-slip coating. The primer is allowed to dry or cure according to the manufacturer's instructions. Next, the anti-slip coating is applied to the steel sheets using a suitable method, such as spraying, rolling, or brushing. The coating is evenly distributed and applied in the desired thickness to ensure effective slip resistance. After the coating is applied, it is left to dry or cure according to the product specifications. This may involve air drying or using heat to accelerate the drying process. Once the coating is completely dry and cured, the steel sheets are ready for use. The anti-slip coating provides a textured surface that enhances traction and reduces the risk of slipping, making it suitable for various applications where slip resistance is crucial.

- Q:Are the steel sheets resistant to scratching or abrasion?

- Yes, steel sheets are highly resistant to scratching or abrasion. Steel is known for its exceptional durability and strength, making it resistant to various forms of damage, including scratches and abrasions. The smooth and hard surface of steel sheets makes them less susceptible to scratches caused by sharp objects or rough surfaces. Additionally, the strong molecular structure of steel prevents it from easily wearing down or getting scratched, ensuring its longevity even in high-traffic or demanding environments. Overall, steel sheets are an excellent choice when it comes to resistance against scratching or abrasion.

- Q:What are the different surface textures available for steel sheets?

- Some of the different surface textures available for steel sheets include smooth, brushed, matte, textured, embossed, and patterned.

- Q:Are steel sheets suitable for automotive body panels?

- Indeed, automotive body panels can be effectively constructed using steel sheets. The automotive industry heavily relies on steel due to its exceptional strength and durability. Steel sheets possess the ability to endure the various pressures and strains encountered by body panels during vehicle operation, including impacts, vibrations, and adverse weather conditions. Moreover, steel can be effortlessly molded into intricate shapes, making it an optimal material for designing diverse body panel components. Furthermore, when adequately treated and coated, steel exhibits remarkable resistance against corrosion, guaranteeing the longevity and aesthetic appeal of the vehicle. In conclusion, steel sheets possess all the essential characteristics necessary for automotive body panels, rendering them a fitting choice for manufacturers.

- Q:What is the maximum length of a steel sheet?

- The maximum length of a steel sheet can vary depending on various factors such as the manufacturing capabilities of the steel mill, transportation limitations, and customer requirements. However, in general, steel sheets can be produced in lengths ranging from a few feet to several hundred feet. Industrial-sized steel mills are capable of producing exceptionally long steel sheets, often exceeding 100 feet or more. These extended lengths are typically utilized in large-scale construction projects, such as bridges, industrial buildings, or shipbuilding. However, it is essential to note that the maximum length of a steel sheet is subject to practical constraints, such as the size of transportation vehicles or the limitations of handling equipment. Therefore, while it is possible to manufacture steel sheets of considerable length, practical considerations may restrict the maximum length that can be effectively utilized in different applications.

- Q:How do steel sheets perform in terms of scratch resistance?

- Renowned for their exceptional ability to resist scratches, steel sheets are widely recognized for their strong and durable nature. This quality makes them highly suitable for a multitude of applications where they may come into contact with objects or surfaces that could potentially cause damage. Moreover, steel sheets possess the capacity to endure regular wear and tear, rendering them particularly suitable for demanding environments with heavy usage. Furthermore, the scratch resistance of steel sheets can be further enhanced by applying coatings or finishes, thereby achieving an even higher level of protection. In summary, the outstanding scratch resistance of steel sheets has earned them a well-deserved reputation as a reliable choice for a diverse range of industrial and commercial purposes.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Galvanized Corrugated Iron Sheet for Roofing

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords