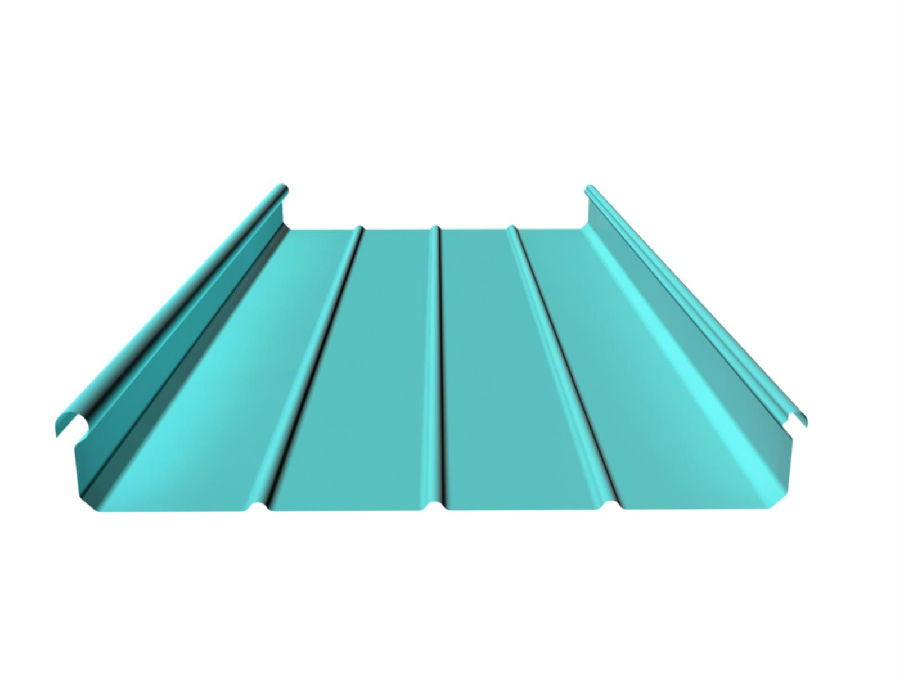

Galvanized Color steel Plate roofing Corrugated

- Loading Port:

- Nanjing

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4000 PCS

- Supply Capability:

- 38000 PCS/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Galvanized Color steel Plate roofing Corrugated Details

Standard: | AISI,ASTM,BS,DIN,GB | Grade: | Q235,Q345,Q195 |

Technique: | Cold Rolled | Color: | many color |

Thickness: | 0.8mm-4mm,0.3mm-1mm | Surface Treatment: | Coated |

Width: | 600mm-1250mm | Length: | as oer customer's requirement |

experience: | more tahn 8 years | Thickness tolerance: | as per standard |

Type: | Steel Plate |

Packaging & Delivery

Packaging Detail: | Standard Export Package |

Delivery Detail: | 15-30 working days after receive the deposit |

Galvanized Color steel Plate roofing Corrugated Specifications

Corrugated steel sheet

Prompt Delivery

Flexible Payment Terms

Market:Middle East,Asia

Galvanized Color steel Plate roofing Corrugated Services

Our samples can be offerd with sample charged and curier fee by buyer's side

we have full stock, and deivery in short time, many styles with your choices

Good quality+factory price +Quick pesponse +Relablie service, is what we are best trying with you.

All of the products produce by our professionl workman and we have our high-work- effect foreign trde team, you kan totally believe our service.

After you choose, we will count chepest shipping cost and make invoie to you.

Check quality again, and send out to you 1-2 working days after your payment.

Galvanized Color steel Plate roofing Corrugated Pictures

- Q:How do steel sheets perform in terms of chemical resistance?

- Steel sheets have excellent chemical resistance due to their inherent properties such as high corrosion resistance, durability, and stability. They can withstand exposure to a wide range of chemicals, acids, bases, and solvents without significant deterioration or reaction. However, the specific performance of steel sheets in terms of chemical resistance may vary depending on the type of steel alloy used and the concentration and duration of exposure to different chemicals.

- Q:How are steel sheets protected during transportation by air?

- Steel sheets are protected during transportation by air through various measures such as packaging them in protective covers, using cushioning materials like foam or bubble wrap, securing them with straps or bands to prevent movement, and placing them in sturdy crates or pallets to minimize the risk of damage. Additionally, some steel sheets may undergo corrosion-resistant coatings or be stored in climate-controlled containers to protect them from moisture or extreme temperature changes during transit.

- Q:Are steel sheets suitable for elevator shafts or cabin interiors?

- Steel sheets are suitable for both elevator shafts and cabin interiors. They are widely used in the construction industry because of their strength, durability, and versatility. Elevator shafts commonly utilize steel sheets due to their ability to withstand heavy loads and provide structural support. Additionally, they offer excellent fire resistance and can endure extreme temperatures, ensuring a safe environment. Regarding cabin interiors, steel sheets provide numerous advantages. They can be easily shaped and sized to allow for customization and design flexibility. Moreover, steel sheets can be painted or coated, resulting in a smooth and visually appealing finish. They are highly resistant to wear and tear, guaranteeing long-lasting durability in high-traffic areas such as elevator cabins. Furthermore, steel sheets possess soundproofing properties, which are essential for creating a comfortable and quiet experience for passengers in elevator cabins. Additionally, they resist moisture and corrosion, making them suitable for elevator cabins located in humid or coastal regions. In conclusion, steel sheets are an exceptional choice for elevator shafts and cabin interiors due to their strength, durability, versatility, fire resistance, soundproofing capabilities, and resistance to moisture and corrosion.

- Q:What is the difference between a laminated and non-laminated steel sheet?

- A laminated steel sheet is formed by layering multiple thin sheets of steel together, while a non-laminated steel sheet is made from a single solid piece of steel. The lamination process enhances the strength and durability of the sheet, making it more resistant to bending, warping, and corrosion. On the other hand, non-laminated steel sheets are generally less expensive and may be easier to work with due to their uniform composition.

- Q:Are steel sheets suitable for food storage applications?

- Food storage applications can benefit greatly from the use of steel sheets. This material offers exceptional durability and versatility, with its resistance to corrosion making it an ideal option for storing food. Steel sheets create a hygienic and secure environment for food, as they are non-porous and do not retain odors or flavors. Moreover, they provide reliable protection against contaminants and pests, ensuring the maintained quality and freshness of the stored food. Furthermore, steel sheets are effortlessly cleaned and maintained, making them the perfect choice for food storage facilities, restaurants, and any other setting where food safety is of utmost importance.

- Q:What's the density of the 0.5 color steel plate?

- The traditional coating is divided into several categories, the most high-grade is fluorocarbon coating, almost 20 years of anti-corrosion. Generally from the steel mill to reel in the form of distribution to all parts.

- Q:What is the process of applying protective coatings to steel sheets?

- The process of applying protective coatings to steel sheets typically involves several steps. First, the steel sheets are thoroughly cleaned and prepared to ensure a clean and smooth surface. This may involve removing any existing rust, dirt, or contaminants. Next, a primer or base coat is applied to the steel sheets. The primer helps to promote adhesion between the steel surface and the protective coating. It also provides additional corrosion resistance. After the primer has dried, the main protective coating is applied. This coating can vary depending on the specific requirements and intended use of the steel sheets. Common types of protective coatings for steel include epoxy, polyurethane, or powder coatings. The coating is carefully applied to ensure an even and consistent coverage. Once the protective coating has been applied, the steel sheets are typically cured or dried according to the manufacturer's instructions. This allows the coating to fully bond and harden, increasing its durability and resistance to corrosion. Overall, the process of applying protective coatings to steel sheets involves cleaning and preparing the surface, applying a primer, applying the main protective coating, and properly curing or drying the coating to ensure optimal performance.

- Q:What are the different surface gloss levels available for steel sheets?

- The different surface gloss levels available for steel sheets include matte, satin, and high gloss.

- Q:Can the steel sheets be used for industrial machinery?

- Industrial machinery can indeed utilize steel sheets. Steel, known for its robustness, endurance, and resistance to damage, is a favored option for constructing industrial machinery. By shaping, cutting, and welding steel sheets, manufacturers can produce diverse components and parts essential for industrial machinery. The adaptability of steel empowers manufacturers to design and fabricate machinery that precisely meets specifications and demands. Furthermore, steel's capacity to endure hefty burdens, extreme temperatures, and corrosive surroundings renders it suitable for a vast array of industrial applications.

- Q:Are the steel sheets suitable for welding or fabrication purposes?

- Yes, steel sheets are suitable for welding or fabrication purposes. Steel is a versatile and commonly used material in various industries, including construction, automotive, and manufacturing. Steel sheets provide a strong and durable base for welding and fabrication processes. They can be easily cut, shaped, and joined together through welding techniques such as arc welding, MIG welding, or TIG welding. Steel sheets also offer excellent structural integrity and can withstand high temperatures and mechanical stress during welding or fabrication. Additionally, steel sheets are available in different thicknesses and grades, allowing for customization based on specific welding or fabrication requirements.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Galvanized Color steel Plate roofing Corrugated

- Loading Port:

- Nanjing

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4000 PCS

- Supply Capability:

- 38000 PCS/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords