GALVALUME Galvanized Steel Corrugated Roof Panel / Wall Panel / plate /Sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

GALVALUME Galvanized Steel Corrugated Roof Panel / Wall Panel / plate /Sheet

Quick Details

| Standard: | AISI, ASTM, BS, DIN, GB, JIS | Grade: | SGCC ,Q235 ,SPCC ,DC01, DX51D+Z | Thickness: | 0.15-1.2mm |

| Type: | Steel Plate | Technique: | cold rolled or hot rolled | Surface Treatment: | Galvanized,Chromated, dry or oiled |

| Application: | roofing sheet | Special Use: | High-strength Steel Plate | Width: | 790-1025mm |

| Length: | 1000-6000mm | price term: | FOB CFR CIF |

Specifications

price:advantage

delivery:fast

packing:as your requirment

Thickness | 0.13-0.8mm |

Width | 650-1100mm |

Length | 1700-5800mm |

Zinc / AZ coating | 50-275g/m2 |

Pitch | 76mm |

Wave height | 18mm or as request |

Wave No. | 8-12 |

Type | steel plate |

Weight of each package | about 3 mt |

Technology | cold rolled |

Material | SGCC SGCH SPCC DX51D+Z SGLCC DX51D+AZ |

Standard | ASTM,GB,JIS,DIN |

Price | FOB USD700-900 per mt |

Packing | packed in iron sheet lined with kraft paper or as per client's request. |

Surface treatment | galvanized,corrugated,bright finished,chromated,oiled(or unoiled)

|

Delivery time | within 20 days after receiving the down payment or irrevocable L/C at sight

|

Payment | 30% down payment of the total value by T/T and the balance must be paid by T/T or irrevocable L/C at sight after the goods finished. |

Application

a.) Attractive and innovative appearance, rich colors, decorative, flexible combination, can express a different architectural style;

b.) Light weight, high mechanical properties;

c.) Anti-earthquake, fire, rain, long life, no maintenance;

d.) Installation is simple, shorten the construction period;

e.) Environmental protection, etc.

a.) Industrial and civil buildings, warehouse;

b.) Special construction;

c.) Steel structure houses and mobile homes, roof, walls, and interior and exterior decoration, etc.

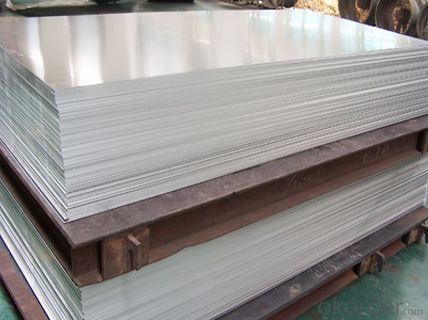

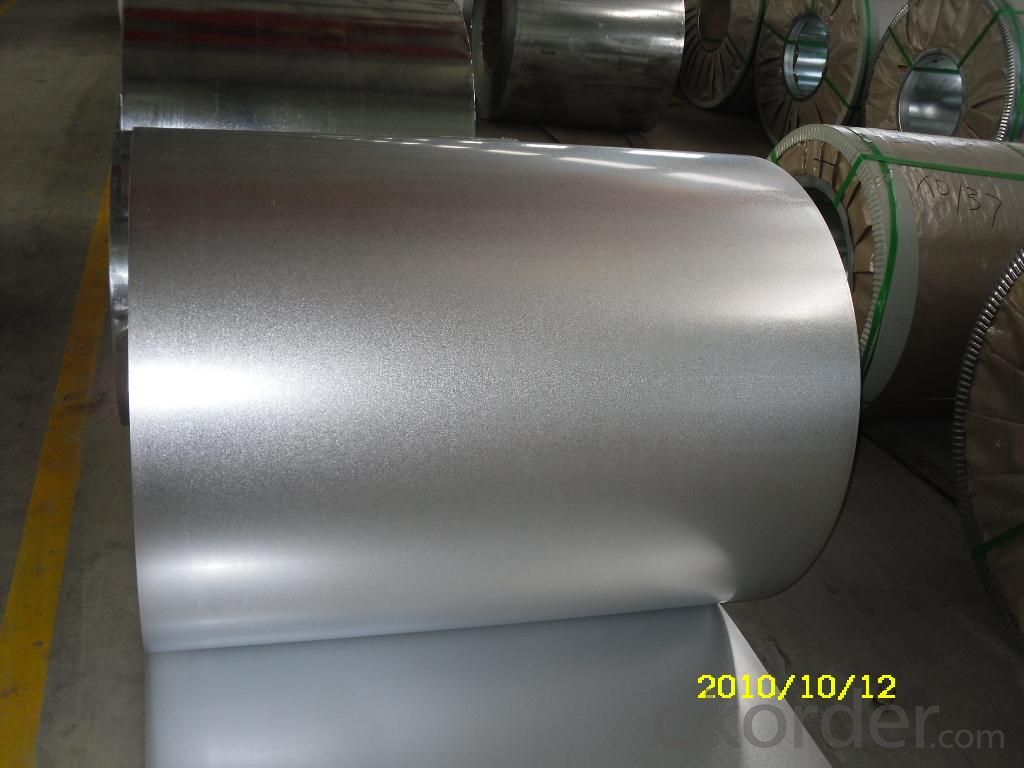

Picture:

- Q:How is the quality of steel sheets determined?

- The quality of steel sheets is determined by various factors such as the composition of the steel, its mechanical properties, surface finish, and dimensional accuracy. It undergoes rigorous testing for strength, ductility, hardness, and resistance to corrosion. Additionally, the manufacturing process, including the selection of raw materials and adherence to industry standards, plays a significant role in determining the quality of steel sheets.

- Q:Stainless steel plate and steel welding

- With almost 2.5 of the welding, and certainly not the same as before the color. You can buy acid lotion passivation, and then washed with water, basically with stainless steel, the original color is not much

- Q:What are steel sheets used for?

- Steel sheets are commonly used for various applications such as construction, automotive manufacturing, appliances, and packaging, due to their durability, strength, and versatility.

- Q:What is the average cost of installing steel sheets?

- The cost of installing steel sheets can differ depending on several factors, including project size, steel sheet type and quality, location, and labor expenses. On average, the installation cost varies between $7 and $15 per square foot. Nevertheless, it is crucial to acknowledge that this is merely a general approximation, and actual expenses might differ significantly. It is advisable to obtain quotations from multiple contractors or steel suppliers to acquire a more precise estimate tailored to a specific project.

- Q:What are the properties of steel sheets?

- Steel sheets possess several desirable properties that make them highly sought after in numerous industries. Firstly, their exceptional strength and durability are well-known. They have the ability to withstand heavy loads and exhibit a high resistance to impact and deformation. Consequently, they are considered ideal for applications where strength is paramount, such as in the construction, automotive, and aerospace sectors. Another noteworthy characteristic of steel sheets is their excellent corrosion resistance. Typically, steel is coated with a thin layer of zinc or other protective materials to prevent rusting and corrosion. This protective coating enhances the longevity of steel sheets, enabling their use in outdoor or humid environments without the risk of degradation. Steel sheets are also renowned for their versatility. They can be easily bent, shaped, and welded, making them suitable for various fabrication processes. This adaptability empowers manufacturers to effortlessly create intricate structures and components, rendering steel sheets a popular choice in architectural and industrial designs. Furthermore, steel sheets exhibit excellent thermal conductivity. This property enables them to efficiently transfer and distribute heat, making them well-suited for applications that require temperature regulation, such as in heating systems or electrical appliances. Lastly, steel sheets are highly recyclable, rendering them an environmentally-friendly option. Steel is one of the most recycled materials worldwide, and the recycling process does not compromise its properties or quality. This sustainability factor establishes steel sheets as the preferred choice for those seeking eco-friendly materials. In conclusion, the properties of steel sheets encompass strength, durability, corrosion resistance, versatility, thermal conductivity, and recyclability. These qualities make steel sheets a reliable and versatile material for a wide range of industries and applications.

- Q:What is the difference between a black and pickled steel sheet?

- A black steel sheet refers to a plain carbon steel sheet that has not undergone any additional surface treatment. It has a characteristic dark appearance due to the presence of an iron oxide scale on its surface. On the other hand, a pickled steel sheet has undergone a surface treatment process called pickling, which involves removing the oxide scale using an acid solution. This treatment results in a clean and smooth surface, making it more suitable for further processing or application.

- Q:Can the steel sheets be easily drilled or machined?

- Steel sheets can be drilled or machined with ease. The versatility of steel allows for easy manipulation using a range of tools and techniques. Drilling and machining steel sheets is a widely practiced method in industries like construction, manufacturing, and engineering. By employing the appropriate equipment and expertise, one can create holes, mold the material, or attain precise dimensions required for a specific purpose.

- Q:How do steel sheets perform in corrosive environments like saltwater?

- Steel sheets can be prone to corrosion in saltwater environments due to the presence of chloride ions. However, their performance can vary depending on the type of steel and the protective measures taken. Stainless steel sheets, for example, contain chromium which forms a passive layer that prevents corrosion. Additionally, surface treatments such as galvanization or applying protective coatings can further enhance their resistance to corrosion in saltwater.

- Q:What does steel plate "A3" mean?

- Using Q235 steel as punch material, after quenching without tempering, direct use, hardness of 36~40HRC, solved the punch in use in the phenomenon of fragmentation

- Q:What is the typical price difference between galvanized and non-galvanized steel sheets?

- The price difference between galvanized and non-galvanized steel sheets typically fluctuates based on various factors, including the steel grade, market conditions, and the size and quantity of the sheets. Generally, non-galvanized steel sheets are slightly less expensive than galvanized ones. Galvanization is a process that involves applying a protective zinc coating to the steel, which helps prevent rust and corrosion. This extra layer of protection enhances the steel's durability and lifespan, making it suitable for outdoor use or in environments exposed to moisture or chemicals. The cost of galvanizing steel includes additional manufacturing steps, such as cleaning, dipping the steel in molten zinc, and post-treatment processes. These additional steps contribute to the higher price of galvanized steel sheets compared to their non-galvanized counterparts. As a rough estimate, the price difference between galvanized and non-galvanized steel sheets can range from 10% to 30%. However, it's important to note that this is a general range, and actual prices may vary depending on the specific market conditions and supplier pricing. To obtain accurate and up-to-date pricing information for galvanized and non-galvanized steel sheets in your specific region or market, it is advisable to consult with steel suppliers or conduct market research.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

GALVALUME Galvanized Steel Corrugated Roof Panel / Wall Panel / plate /Sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords