Gabion Reno Mattress 3mx1mx0.5m/Direct Factory

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 set

- Supply Capability:

- 5000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

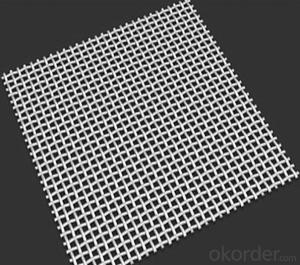

Features of gabion reno mattress(GRM-1002683):Reno mattresses, are gabion type structures, they are manufactured from 6 x 8 double twist mesh with more planar area and relatively small in thickness.Reno Mattresses are used for river bank and scour protection, channel linings for erosion control, and embankment stability. They are flexible, permeable structures to promote rapid growth of natural vegetation.

Specification of gabion reno mattress (GRM-1002683) is according to ASTM-A975-97,Macaferri standard,

1.Mesh type:60 x 80 mm

2.Size:3x1x0.5m

3.Mesh wire:2.7mm diameter steel wire

4.Selvedge wire:3.4mm diameter steel wire

5.Lacing wire:2.2mm

6.Diaphragms:1x0.5m

7.Product number:GRM-1002683

| Standard Gabion Size | |||

| Length(m) | Width(m) | Height(m) | Cells |

| 1.0 | 1.0 | 1.0 | 1 |

| 1.5 | 1.0 | 1.0 | 1 |

| 2.0 | 0.5 | 0.5 | 2 |

| 2.0 | 1.0 | 0.5 | 2 |

| 2.0 | 1.0 | 1.0 | 2 |

| 3.0 | 1.0 | 0.5 | 3 |

| 3.0 | 1.0 | 1.0 | 3 |

| 4.0 | 1.0 | 1.0 | 4 |

| 4.0 | 1.0 | 1.0 | 4 |

| Custom sizes are also available | |||

- Q:What is the screen printing plate?

- Is a certain tension by the tension of the screen after the tension on a frame, and then coated with a photoresist on the top and then with a specific pattern of film with UV light after the light washed out of the pattern made of water.

- Q:Is the screen printing the best way? And other printing methods than it?

- If directly on the irregular printed above certainly use the screen, the other to see his bid, you should and your home printing factory to contact

- Q:How to make screen printing layout smooth

- Complete the photosensitive / developed after drying and curing, and then in the layout of a layer of solvent-based paint, dry before the back with a vacuum suction pattern part of the transparent, no vacuum equipment, you can use paint thinner on the back

- Q:What are the characteristics of screen printing?

- Screen printing generally has the following characteristics: not subject to printing the size and shape of the restrictions, the layout of the soft pressure small

- Q:How to clean the screen plate

- The screen is automatically cleaned, rinsed and dried, and the screen is automatically stopped when the set time is reached. The door is opened and the drying time is adjusted by pressing the start switch.

- Q:Screen printing, how to choose the screen

- Stainless steel screen printing network tension good strength high printing effect good for printing precision products such as solar panels circuit board printing

- Q:What is the principle of screen printing?

- Type of printing: no printing - such as inkjet, electrostatic copying, laser. Printed - such as movable type, off, screen.

- Q:What are the reasons for the hair making of the screen plate?

- Ink with hardening agent is also likely to cause the printing ink is not enough to produce the edge of the lack of ink and produce hair phenomenon.

- Q:Screen printing and other printing methods of the difference

- The main features of silk screen are: in any object / material / thickness, including the cylinder can be printed.

- Q:Screen printing ink firmness problem

- If it is PVC tablecloth, you can try to corona the first surface of the printing process, so that the surface tension higher (recommended to 55 - 60 dyne), and then see if there is improvement.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Gabion Reno Mattress 3mx1mx0.5m/Direct Factory

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 set

- Supply Capability:

- 5000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords