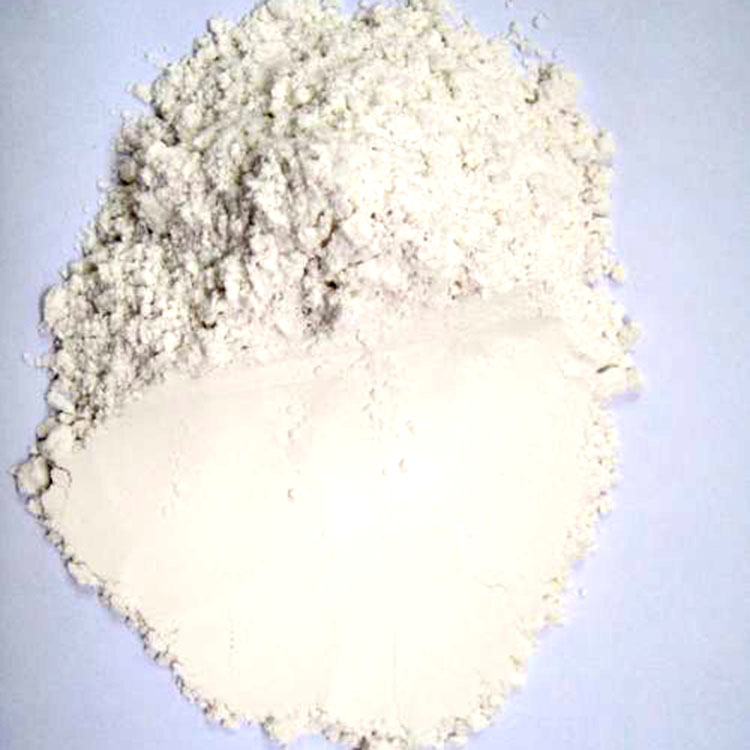

FUSED SILICA FOR REFRACTORY USE 170MESH

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PRODUCT INFORMATION | |

Item | Fused Silica Powder |

Size | D50=9~11um |

Application | Epoxy insulation encapsulant material / Epoxy Molding Compound (EMC), Copper Clad Laminate (CCL), Electromagnetism Industry, Electronic Industry, Ceramic Industry, The Aerospace Industry, Glass Industry, Plastics Industry, Grinding Material Industry, Coating Industry, Investment Casting Industry, Thermal Insulation Product of Calcium Silicate, Refractory Material |

Model No. | R610 |

MOQ | 5 ton |

Material | natural silica rock after melting |

H.S. CODE | 25061000 |

PRODUCT CHEMICAL COMPOSITION AND PHYSICAL PROPERTIES | |

SiO2 | >99.99% |

Al2O3 | <0.015% 1000ppm |

Fe2O3 | <0.002% 50ppm |

Density | 2.2 |

Whiteness | >92% |

Moisture content | <0.05% |

Mohs hardness | 6.5 |

Igniting loss | <0.12% |

Appearance | powder |

- Q:How to distinguish the fire?rating of rubber and plastic thermal insulation material?

- Fire?rating grading of external wall thermal insulation materials. 1, China's national standard GB8624-97 divides the combustion performance of building materials external insulation materials into the following grade. Level A: Incombustible materials: Almost no burning materials. Level B1: Incombustible materials: Flame-like material has good fire-retardant effect. In case of fire in the air or at high temperature, it is difficult to fire and doesn't spread quickly, and when the fire source is removed after combustion, it stops immediately. Level B2: Incombustible materials: Combustible materials have a certain flame resistance. In case of fire in the air or at high temperature, it will immediately burst into flames, and easily leads to the spread of fire, such as poles, wooden frame, wooden beams and wooden stairs,ect. Level B3 : Incombustible materials: No flame-retardant effect, hidhly flammable and high fire risk. 2, The external wall thermal insulation materials could be divided according to the fire?rating. 1) thermal insulation material that has the level A combustion performance: Spraying inorganic fiber, glass wool, foam glass, ceramic foam, rock wool, foam cement and perlite obturator, and so on. 2), The thermal insulation material that has level B1 combustion performance: Special processed extruded polystyrene board (XPS) / special processed polyurethane (PU), phenolic and polystyrene powder. 3), Thermal insulation materials that have level B2 combustion performance: Molded polystyrene board (EPS), extruded polystyrene board (XPS), polyurethane (PU) and polyethylene (PE), etc. The information given is for reference only. Hope it will help you.

- Q:How to use fire-resistant soil?

- It can live with water, not too sticky. Don't be too thin. It's best to put the stove in the inner wall.

- Q:Using what kind of melting aluminium furnace refractories is more appropriate?

- If it's the ordinary, you can use high aluminum refractory brick with general clay, GB/T 3994-2005 clay heat insulation refractory brick. If you need these with good material, there is high alumina thermal insulation refractory brick, GB/T 3995-2006 high aluminum heat insulation refractory brick, models have A13 and material is the alumina, A13 50 u, high insulating brick B5.Intermediate insulating brick B2, etc. Dolomite brick: good hang kiln performance, good erosion resistance, but brick is usually without f - CaO, hydration, and difficult to transport and storage, less used in the production. Magnesia-chrome bricks: good hang kiln, used in calcining zone. The disadvantage is that its thermal shock resistance is poor and plus hexavalent Cr is toxic, the production and use of magnesite chrome bricks in international countries gradually reduce. Now unit using the brick find replacements as soon as possible.

- Q:Who knows how many fire heat preservation material are there?

- They can be divided into wood fire, steel fire and stainless steel fire. Wooden fireproofing material is light weight, easy for installation and second decoration, as well as all types of civil construction and some industrial buildings. It can be realized through inorganic insulation materials, such as glass wool, rock wool, foam glass etc.. The phenolic foam materials inside organic foam material is more special. Phenolic foam does not only have a good thermal insulation performance, but also can be combined with steel and other materials, to achieve a class A fire retardant level. Class A thermal insulation include: 1 thermal insulation materials with class A combustion performance Fire insulation materials of fire barrier zone can use class A material with class A combustion performance in rock (ore) cotton, foam glass, inorganic thermal insulation mortar.

- Q:How can the furnace be replaced after the gasifier or water wall is replaced with refractory material?

- The simplest is to find a refractory construction unit, should provide you with oven curve.

- Q:What is the new fireproofing standard of external wall thermal insulation materials?

- The new national standard "Fireproof? Specification of Building Design" (GB50016-2014) has been issued, it will be carried out from May 1, 2015. Compared with "Fireproof? Specification of Building Design" GB 50016-2006 and "fire?safety?rules of tall buildings design" GB 50045-95 (2005 edition), the major changes of new standard is the following: 1. It has combined with "Fireproof? Specification of Building Design" and "Fireproof? Specification of Tall Buildings Design", and has adjusted incompatible requirements between two standards, and has unified the classification of residential buildings in accordance with the building height; 2. It has increased two chapters including the fire-fighting rescue facilities and wooden structures, and has improved the requirements for fire fighting and rescue, and standardized the fireproofing requirements of wood construction; 3. Additional requirements for the fireproofing requirements of building external insulation system; 4. The fire-fighting equipment is written in a separate chapter and improve relevant contents; cancel the design requirements of fire water supply system and smoke control system, and they are regulated by the relevant national standards; 5. appropriate increase in the high-rise residential buildings and fireproofing technical requirements for high-rise civil building whose height is greater than 100m; 6. add the fireproofing requirements used by covered pedestrian during evacuation; adjust and add designers density of construction materials, furniture, lighting shops and exhibition hall; 7. add the fireproofing requirements of underground warehouses, logistics buildings, large combustible gas tank (zone), ammonia storage tanks, LNG storage tank, and adjust the fire?separation distance of liquid oxygen tank; 8. improve the relevant requirements to prevent vertical or horizontal spread of building fire.

- Q:How to divide the fire rating standards of insulation materials?

- The fire rating classification standards of insulation materials, 1. Insulation materials with A-level combustion performance: inorganic fiber spraying, rock wool, glass wool, foam glass, ceramic foam, foam cement, close-celled perlite, etc. 2. Insulation materials with B1-level combustion performance: specially-treated extruded polystyrene boards(XPS)/ specially-treated Polyurethane(PU), Phenolics, Polystyrene rubber powder particles,etc. 3. Insulation materials with B2-level combustion performance: Expanded polystyrene sheets(EPS), Extruded polystyrene board(XPS), Polyurethane(PU), Polyethylene(PE), etc.

- Q:What are unshaped fire-resisitance materials?

- Refractory castable, refractory plastic material, usually classified according to construction and manufacture method, unfired bricks precast block, refractory pressed into material, refractory cast material, refractory coating, refractory ramming material there are many classification methods

- Q:I wanna ask about the building insulation materials fire rating?

- In China, the main external insulation materials are divided into level A, level B1, level B2 and level B3. According to the current "Combustion Performance Classification Method of Building Materials", level A thermal insulation material is incombustible material and inorganic insulation material. However, there are few level A thermal insulation material on the current market, only glass wool, rock wool board, foam glass and vitrified micro bead. However, compared with level A insulation material, the organic insulation materials are popular in the market. Level B insulation material can be divided into three levels, level B1 is flame-retardant, level B2 is flammable, and level B3 is flammable. Level B1 nonflammable thermal insulation material is determined by the fire endurance of the material, in addition, different parts of material is divided differently! More common is EPS / XPS insulation boards which have added flame retardant through special treatment. B2 level of combustible insulation materials, common to EPS expanded polystyrene foam insulation board and XPS board, that is, we often say that the general board. The ignition point of this material is very low, and it will release a large amounts of harmful gases in the combustion process. level B3 flammable insulation material is a kind of thermal insulation material which mainly made of polyphenyl foamed. Since this material is highly flammable, it has been eliminated. Civil construction insulation materials, popular building insulation materials in China's current market are mainly made by three organic foam, such as EPS (molded polystyrene board), XPS (extruded polystyrene board) and PU (polyurethane)

- Q:What are the materials of insulation firebricks?

- The furnaces of firebricks are generally divided into two types, namely, unshaped refractory materials and shaped refractory materials. Unshaped refractory materials, also called castables, is a mix of powdery particles of many aggregates and one or multiple adhesives. They must be stirred well with one or multiple liquids when in use, which has a strong liquidity. Unshaped refractory materials generally refers to firebricks. They have standard rules about their shapes and can also be processed temporarily as needed.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

FUSED SILICA FOR REFRACTORY USE 170MESH

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords