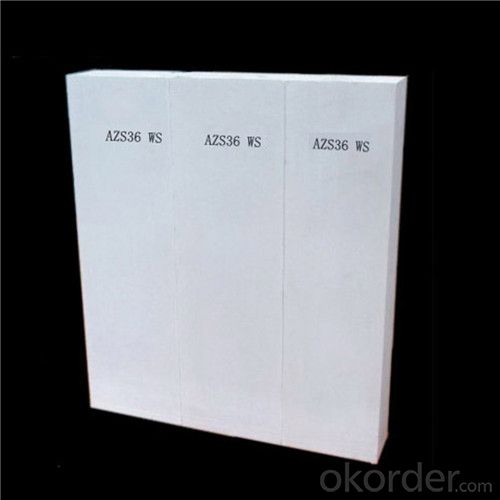

Fused Cast Zirconia Alumina Brick for Sodium Silicate Furnace

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Zirconia Alumina Brick Features:

1.Casted by melting raw material in the mold, then cooling and solidification.

2.Strong glass corrosion resistance and high thermal shack stability.

3.Good wear-resistance,dregs-resistance and alkali corrosion resistance.

4.High-purity raw material, barely no pollution.

5.Top quality, long service time.

Zirconia Alumina Brick Applications:

1.Sodium silicate furnace, ceramic frit furnace, glass furnace, etc.

2.Important parts of furnaces where chemical erosion is serious and temperature changes frequently.

3.Lining of glass furnace.

4.The chemical industrial, metallurgical furnaces.

Zirconia Alumina Brick Physical and chemical index:

Item |

unit | Properties | ||||||||||

AZS—33 | AZS—36 | AZS—41 | ||||||||||

Y | H | Y | H | Y | H | |||||||

Al2O3 | % | Residual quantity | ||||||||||

ZrO2 | ≥ | 32 | 35 | 40 | ||||||||

SiO2 | ≤ | 16 | 17 | 13.5 | 14.5 | 13 | 14 | |||||

Na2O | 1.5 | 1.4 | 1.3 | |||||||||

Fe2O3+TiO2+CaO+MgO +Na2O+K2O+B2O3 | 2.5 | 3.0 | 2.5 | 3.0 | 2.5 | 3.0 | ||||||

Glass phase exudate temperature | ≥ | °C | 1400 | 1080 | 1400 | 1100 | 1400 | 1150 | ||||

% Thermal expansion rate | 1000°C | 0.8 | ||||||||||

1500°C | 0.8 | |||||||||||

Cold Crushing strength Mpa | 350 | |||||||||||

Bulk density,g/cm3 | PT,QX | ≥ | KG/dm3 | 3.40 | 3.30 | 3.45 | 3.4 | 3.55 | 3.50 | |||

MS | 3.50 | 3.45 | 3.60 | 3.55 | 3.70 | 3.65 | ||||||

WS | 3.60 | 3.55 | 3.70 | 3.65 | 3.80 | 3.75 | ||||||

True density,g/cm3 | 3.8-3.9 | |||||||||||

Crystal phase composition | Item | Inclined zircon | Alpha corundum | Glass phase | ||||||||

AZS—33 | 32 | 47 | 21 | |||||||||

AZS—41 | 40 | 43 | 17 | |||||||||

Application | PT,QX | ZWS | WS | |||||||||

sodium silicate furnace,ceramic frit furnace , glass furnace,and other furnaces | ||||||||||||

FAQ

Q1: How do you control the products quality?

A1: With strict quality control system throughout the materials selection and production process, our refractory and ceramic fiber products quality is effectively controlled to meet customer requirements. From the raw materials selecting, our quality control begin. The quality certificates of raw materials are required and each batch will be tested before using. During production, the quality control is conducted by workers and then each piece will be sorted and examined by quality supervisor.

Q2: What`s the lead time for my order?

A2: It depends on customers’ requirements and our production schedule. And usually we need 30-60 days for refractory bricks, 10-25 days for unshaped refractory materials and 10-20 days for ceramic fiber blankets

- Q:What's the use of refractory bricks?

- Refractory brick fire resistance is greater than 1580 degrees, and the average brick three or four Baidu softened deformation. The refractory brick because of its high refractoriness, and high pressure molding, and after high temperature kiln, so the use of strength is particularly good, practicality is particularly strong in high temperature liquid, gas with high temperature, high temperature solid, chemical corrosion products etc..

- Q:What are the main constituents of refractory bricks?

- According to the composition of refractory bricks, they can be divided into five major categories, namely, silicon aluminum refractory bricks, basic series refractory bricks, carbon containing refractory bricks, zirconium containing refractory bricks and insulating refractory bricks. Any furnace is not made of only one kind of refractory brick, and it needs different fire bricks to match with each other. The following five categories of refractory bricks are described in detail.

- Q:How can the silica in zircon sand be removed during the smelting of zirconium corundum?

- Fused zirconia corundum brick is pure alumina and zirconia containing silica 65%, about 34% of the zircon sand in electric furnace melting after internalization into moulds cooling and the formation of the white solid, the petrographic structure by zirconium corundum and plagioclase eutectoid and glass phases, from the phase is eutectoid zirconium corundum and plagioclase phase, glass phase filling between their crystallization.

- Q:What material is good for refractory bricks?

- According to the composition of refractory bricks, they can be divided into five major categories, namely, silicon aluminum refractory bricks, basic series refractory bricks, carbon containing refractory bricks, zirconium containing refractory bricks and insulating refractory bricks.

- Q:Just what is in the furnace material?

- Referred to as refractory brick. Refractory made from refractory clay or other refractory material. Light yellow or brownish. The utility model is mainly used for laying smelting furnaces, and can withstand high temperature between 1580 DEG C and 1770 DEG C.

- Q:What are ordinary bricks, refractory bricks, hollow bricks?

- Referred to as refractory brick. Refractory wood made from refractory clay or other refractory material

- Q:Zirconium corundum 25 content and 40 content, how to distinguish in appearance?

- It is in the production process, zirconium corundum bricks are likely to cause pollution.

- Q:What are kiln bricks?

- Refractory materials are generally divided into two kinds, namely unshaped refractory and shaped refractory. Unshaped refractory castable is also called, is composed of a variety of aggregate or aggregate and one or more adhesive powder particles, and must use one or more liquid with stirring, has strong liquidity. Refractory materials generally refers to the shape of a refractory brick, standard rules, can also according to need to be cut when the temporary processing.

- Q:Outside wall tile (whole body smooth surface has small hole split brick) has cement pollution, with what product cleaning (cement, mortar, cleaning agent)?

- Tile has a long period of cement pollution, a variety of weak acid cleaning can be removed, such as oxalic acid, acetic acid and so on, of course, the use of special cleaning agent is perfect. But the cost is higher.

- Q:What are the specifications for bricks?

- In a proper ratio of lime sand brick and quartz sand, sand or fine sand, the ground, Kazumi Wa, semi dry pressing and autoclaved curing and. The fly ash brick is made of fly ash as main raw material and mixed with cement material such as coal gangue, stone powder or clay. It is made up of batching, molding, drying and roasting. It can make full use of industrial waste residue and save fuel.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Fused Cast Zirconia Alumina Brick for Sodium Silicate Furnace

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords