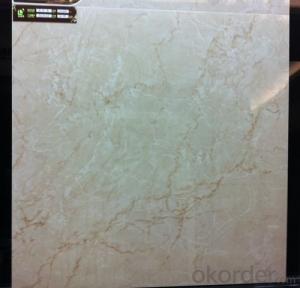

Full Polished Glazed Porcelain Tile 600 XD6B101

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1152 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Basic Information:

Tile Type | Full Polished Glazed Porcelain Tile |

Certificate | ISO13006, ISO9001 |

Finish | Nano Finish |

Size | 600x600mm |

Water Absorption Rate | Below 0.5% |

Packing | Carton + Wooden Pallets |

Usage | Floor and wall |

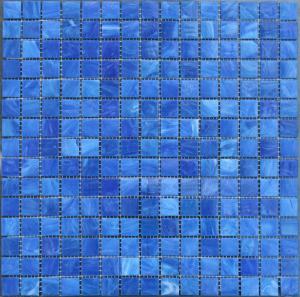

Other Choices | many designs, size, colors |

Delivery Time | 15~20 days after 30% deposit received |

Features:

l Available in many designs, specifications and assorted color, unique designs and exclusive quality

l Used for indoor & outdoor wall and floor decorations, as well as Stair Case Product;

l Easy to install, anti-dust, washable, acid-proof, alkali-proof, durable

l Material: glazed porcelain

l Customized sizes available according to clients’ requirements

l The full polished glazed porcelain tile is widely used for interior house flooring, hotel lobby flooring, shopping mall as well as other public sites.

l Vivid stone texture and vein bring our decoration the natural stone beauty with much lower cost, easier quality control and easier decoration proceeding.

l Advanced glazing technology to make sure the tile surface beauty vivid and clean, via ink-jetting or silk printing.

l We could go with OEM model, making 2nd production based on client’s requirement;

l We could offer flexible service on shipment and better support on payment term;

l Our quality guarantee is based on the strict production procedure, quality controlling on the shade, straightness as well as white degree.

- Q:I will be doing my first tile job soon. I will be removing/replacing the tile on my kitchen countertop. I have got most everything figured out with the exception of removing the existing tile on the backsplash. I believe the tile was placed directly over sheet rock (tract home). Any suggestions on how to remove the tile without too much damage to the sheetrock. If I have to do sheetrock replacement I don‘t think I could ever duplicate the texture now applied to the surronding sheet rock Thanks for any tips.

- Well you can use a hammer and a 1/2 chisel with safety glasses to start. As for sheetrock replacement...since it will be under the tile, the texture wont be seen and shouldnt be a problem. The coat that you will use to adhere the tile to the sheetrock will cover any inperfections caused by the tile removal. Are you talking about sheetrock or wonderboard?, sheetrock is also called drywall. If the base behind the tile is a hard ,cement based backing then just adhere the tile to that. I have never heard of anybody setting tile to sheetrock since it isnt waterproof. Good luck.

- Q:Easiest way to remove stick tile

- If the tiles are loose, a putty knife will lift them off the floor. If the tiles are stuck on tight, they're easier to remove if they're heated. I put a towel on the floor and heated them with a regular iron, then used a putty knife to lift the tiles. You don't need to get them hot, just warm.

- Q:We recently remodeled our kitchen and are now ready to apply something between the counter and wall cabinets. We are thinking of tile. Our cabinets are a light oak. The counters are a marble looking blend of grey, blue, beige. Our appliances are beige. What color tile would look nice for this? Also, could you use 12x12 tile vs 4x4 or the smaller tile or is smaller tile better? We currently have unpainted drywall. Can you install tile with drywall behind? Or do you need that other type of backing?

- you can put tile on drywall, no-prob! prime it first to make it water-proof. i use pro-block. here is a link to help you with colors. have fun!

- Q:My new home has a kitchen with glazed ceramic tiles covering most of the walls.The colour is basically honey brown, but there‘s a hideous purple border (in the same tile size shape) running horizontally vertically all over the place - I‘d say that 20% of the tiles are this colour.I want to reduce all the tiles to one (new) colour.Two guys (both pros) have this to say:GUY 1: Cheapest solution (and least noisy/disruptive) is to use a ‘glass enamel paint‘ over the tiles. I went online and found several manufacturers of this stuff.GUY 2: Scoffed at this and said there was no other way than retiling the whole kitchen.Guy 1 is adamant that it can be done, and the job will last if enough care is taken in preparing the surface.Is he right?Has anyone tried this ‘re-enamelling‘ technique, and were the results OK?Thanks!

- After,,,and still, installing thousands of square feet of tile, and painting thousands of gallons of paint,,, ID NEVER MIX THE TWO. Tile is glass essentially. Test this. Take any paint type you wish, paint some on a spare tile piece, and let it cure,,,no matter glass paint etc,,, sigh. Once it's cured,,, purposely, but even gently, cause abrasions with a coffee mug, drag your toaster oven over it. Stack your dinner dishes on it, etc etc etc. I promise you,,,paint will come off, at some rate, and in some amount of time. Beyond all that, PAINT on any surface where food might come in contact with it, is a bad idea. It will likely be more expensive initially, but as you celebrate your next birthday, then one 5 years from now, NEW tile, or any other counter top substance, will still be there, probably NOT marred. Do you want to touch up paint? Do you want any extra effort to detract from the normal use of the kitchen, or any free time you might have? RE-Enameling is also a way for the manufacturer to gain profit. Rev. Steven

- Q:The tile is one week old. I have had the company pull tiles, regrout and patch. I have new cracks every day. Can I reasonable ask them to start over?

- Are you keeping the grout moist? When you get new tile, you should mop the floor every day with warm water. That should keep the grout from cracking on you. You can sure ask the company to start over. No one wants a cracked tile floor.

- Q:i‘m thinking about laying my own tile. ( this way i could save $2700) yeah, i know its a pain int he butt. BUT i‘m still going to do it because i like doing my own work. I‘m laying down 24x24 tiles. do you have any advice or secrete or techniques to offer? its a straight edge tile so i was thinking about using no spacers. I was also told to spread thinset on the tile in addition to the cement floor.

- 27 hundred dollars? What the hell are ya going to tile, a football field?..Ok, first I would think twice about not using spacers but that's up to you.. When you buy the tile check for the size notched trowel that's recommended and use it on the concrete floor and flat butter the back of the tile, and use a rubber mallet to tap it firm.

- Q:I poured bleach on the tiles in my bathroom and there was an emergency and had to leave home. When I got back the tiles were stained a yellowish color and it used to be smooth but now it‘s all rough like sandpaper. HELP!

- I don't know what type of tiles you have, but if it doesn't have a glazed finish, you may not be able to do much about it. Travertine is a popular natural limestone that is very popular these days and is frequently used in bathrooms. The only drawback is that it is a soft and porous material, so it is much easier to damage that a glazed tile or a natural polished marble. The good news is that it is relatively inexpensive and easy to replace. Call a good tile man and get a quote to refinish and a quote to replace the damaged pieces.

- Q:I just mortared some very porous tiles down and i‘m ready to grout. I‘ve used these tiles before and noticed it‘s pretty tough to get the haze to go away. Should i pre-seal the tile before grouting? if so, what brand or name? Also, do i still use a grout haze remover if needed? And lastly what is your recommended tile sealer to finish the job?

- Yes, yes, yes! Porous tile, natural stone, etc., needs to be sealed prior to grouting. If this tile has a smooth or shiny finish, you need to use unsanded grout so you don't scratch it. They sell commercial cleaner but vinegar and water will take the haze off in most cases. Everyone has their own preferences on sealer, but they're all about the same. Your consideration should be whether you want a shiny or dull finish. Remember, the shiny finish will be slicker when wet than the dull finish.

- Q:I am planning on laying down tile in my dining room and kitchen. I recently saw an offset pattern with 12x12 tiles and liked it. I‘ve now decided to go with the same offset pattern but with 20x20 ceramic tiles. Would I still have to find the center of the room and start tiling out from the center or can I just start at one wall and go from there since i‘ll be using the offset pattern? Thanks in advance.

- Regardless of the pattern layout, starting at the centre will leave an even margin of cuts around the edges. It also allows for the walls being not perfectly straight, or the the corners not being perfectly square. However,it is a good idea to lay a row of dry ties to make sure any cuts along the walls will not be too narrow.

- Q:I would appreciate a double check on this problem. I believe I‘ve saved myself a lot of cutting, but I just want to make sure. My shower is 59 inches wide. My tile is 4.25 inches wide and tall. (square)My spacers are .25 inches wide. The middle point of my shower 29.5 inches. If I move my center line to the right or left by 2 and 1/8 inches I should be able to cover the entire width with 13 tile IF I allow for a 1/8th inch addition in each corner. Is this correct?

- Ok so ignore your center line it does not matter here your tiles are 4.25, your grout lines are .25 and you are trying to get the tile and grout lines into a space that is 59 so if you take 13 tiles you get 55.25 for those tiles you will have 12 standard .25 grout lines totaling 3 giving you a total of 58.25 now from here what I would do instead of adding grout line and caulking on each end is form an L with the next wall (assuming you have 3 walls to tile to enclose the shower) because a standard wall tile is about .25 thick this would give you an 1/8 bead of caulk in each corner. Make sense?

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Full Polished Glazed Porcelain Tile 600 XD6B101

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1152 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products