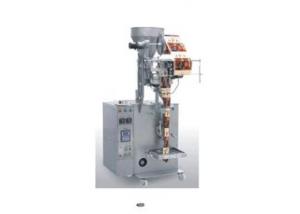

Full Automatic T-shirt Bag Making Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 10 Sets per Month set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Usage of Full Automatic T-shirt Bag Making Machine

This Full Automatic High Speed T-shirt Bag Making Machine is suit for making the uncolor bags made of HDPE, LDPE roll film.

This is a special design of practical type t-shirt bag making machine, operating in fully automatic system. This machine including inverter motor driven system in unwind unit, EPC control for dual line and finish product folding unit. Providing the highest production speed and output .

- special design servo-driven bag feeding is easy to perate.

- Equipped with multi auto alarms and automatic stop design.

- High efficiency production

- The whole pile of bags has the “rocking system”, which would not make the 2pcs of bags, sealing stick together .

Technical data of Full Automatic T-shirt Bag Making Machine

Model | GTHQ-400*2 | |

Bag Size | width (mm) | max. 350 x 2 |

Length(mm) | 650mm | |

Max. Production Speed (cycles/min) | max. 250 | |

Thickness of Film (mm) | 0.008~0.035 | |

Heaters (kw) | 8 | |

Power Required (kw) | 11 | |

Machine weight (kg) | 2700 | |

Outline diameter(L x W x H) (mm) | 5000*2000*1800 | |

The price (FOB NINGBO) | ||

- Q:How much is a bag machine?

- Look at what you want to look like plastic bag machine, and the market on the bag to a lot of models, the price is not the same, of course, a lot of liar company, you must be careful ah, I suggest you directly ask the bag machine business

- Q:What is the filler

- Fillers, also known as fillers, can improve the strength and heat resistance of plastics and reduce costs.

- Q:What is synthetic resin

- Due to the large content, and the nature of the resin often determines the nature of the plastic, so people often see the plastic synonym for the plastic.

- Q:Bag making machine cutting system

- 2, the bag length regulator: bag length adjustment to change the connecting rod set on the eccentric carriage position to control the length of the bag, by tightening the hand wheel and nut to adjust the bag size.

- Q:What is the operation of the shutdown

- 2, cleaning machine health and site health, and the product to the total inspection room.

- Q:Buy plastic bag machine when how to do

- Well, a new machine, I said watching them put the machine installed and then go, they do not let look, let us rest assured that absolutely not the wrong machine.

- Q:How many people need a vest bag machine?

- I would like to do plastic vest bag production but do not understand the specific circumstances, in this advice under

- Q:According to the different production processes can be divided into:

- Spunbond non-woven bags: the polymer has been squeezed out, stretching and the formation of continuous filament, the filament laying into a net, fiber and then through their own bonding, thermal bonding, chemical bonding or mechanical reinforcement method

- Q:Classification and Application of Plastic Bag Making Machine

- (1) high pressure polyethylene plastic bags (2) low pressure polyethylene plastic bags

- Q:Watermarked non-woven bag production process

- Wash the plate without chemical solvents, can be washed directly with water.

1. Manufacturer Overview |

|

|---|---|

| Location | Zhejiang,China (Mainland) |

| Year Established | 1996 |

| Annual Output Value | US$2.5 Million - US$5 Million |

| Main Markets | 7.69% North America 7.69% South America 7.69% Eastern Europe 7.69% Southeast Asia 7.69% Africa 7.69% Oceania 7.69% Eastern Asia 7.69% Western Europe 7.69% Central America 7.69% Northern Europe 7.69% Southern Europe 7.69% South Asia |

| Company Certifications | CE License |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Hamburg, Jeddah, Mersin |

| Export Percentage | 51% - 60% |

| No.of Employees in Trade Department | 3-5 People |

| Language Spoken: | English, Chinese |

| b)Factory Information | |

| Factory Size: | 3,000-5,000 square meters |

| No. of Production Lines | 2 |

| Contract Manufacturing | OEM Service Offered Design Service Offered |

| Product Price Range | Low and/or Average |

Send your message to us

Full Automatic T-shirt Bag Making Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 10 Sets per Month set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products