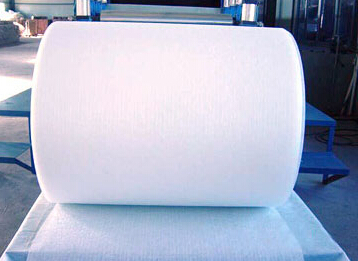

FRP Surfacing Mat- high qulity, low price

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

It is mainly used in the surface layers of FRP products. It is characterized by uniform fiber dispersion, smooth surface, soft hand-feeling, low binder content, fast resin impregnation and good mould obedience.

This line of product falls into two categories: Wrap type \series and hand lay-up type series. The wrap type FRP surfacing mat is most suitable for wrapping FRP pipes and vessels because it is capable of significantly to improve the performances of surface layer to realize longer lifetime and resistance against corrosion leakage and compression.

The hand lay-up type FRP surfacing mat is especially suitable for molding with sophisticated contours while it is characterized by its good mould obedience and fast resin penetration. It is an indispensable material for high quality moulds and FRP products as it is capable of covering up the texture of underlayer to create high gloss surface that gives rise to improved strength and corrosion resistance. The surfacing mats in these two categories are also applicable to other FRP molding processes such as press moulding, spray-up, centrifugal rotating moulding, etc.

- Q:excuse me, when fixing the tile on the external wall of six-floors residential building, the thermal insulation board XPS extruded polystyrene board is using the steel mesh or the glass?fiber mesh.

- it is good to the whole system security and the drawing resistance test of tiles and it should strengthen the XPS plastering mortar and the XPS bond then paste the tile. Using anchor bolt to fix the steel mesh and then paste tiles, then you can carry the force of the anchor to the base wall, a portion of the additional shear and I suggest taking the method of anchor bolt expansion steel mesh.

- Q:Which is better, the polyester polyester net and the glass fiber gauze screen window?

- A window screen made of glass fiber yarn.

- Q:For puttying in decoration, anti-cracking fiberglass mesh or dacron cloth is widely used on walls. What are the correct constrcution order and method?

- For board joints, use white latex strip of cloth to attach bar-type anti-cracking cloth at the seams, and once it's not firm, brush some white latex again.

- Q:How to calculate mesh content?

- The price of mesh material from high to low is successively gold crucible yarn. It is usually from 80 grams to 300 grams per square meter, from a few cents to a few dollars a month. Now the most common is imitated gold pot yarn.

- Q:Should the wall shear walls be hung with fibre nets?

- The role of fiber networks:Cement concrete special reticular fiber into concrete, the concrete mixing process, fiber through the lateral connections between concrete self rubbing and friction role and destroy the formation of monofilament or reticular structure fully open, in order to achieve a large number of polypropylene filament plays on crack effect. The special mesh fiber of cement concrete can effectively control the micro cracks caused by plastic shrinkage, shrinkage and temperature changes of concrete, and prevent and control the formation and development of cracks. As a new kind of anti cracking fiber for concrete, concrete mesh fiber with cement concrete is becoming the focus of research and application of fiber reinforced concrete after glass fiber and steel fiber.

- Q:For a woven glass fiber mesh cloth work

- Glass fiber mesh fabric is based on glass fiber woven fabric as its base material and is coated with high polymer emulsion.

- Q:Is the diamond screen good or invisible or traditional screen?

- Emergency escape: in case of fire accident, the patent has emergency escape function, flexible open lock, free folding open, guarantee the delay of escape precious time, safety out of danger.

- Q:A brief introduction to glass cloth of glass fiber cloth

- The other quality requirements are as follows: the fabric selvedge uniform, flat, smooth cloth is sheetlike, no stains, fluff, creases and wrinkles; the warp and weft density, weight, width and length are consistent with the standard; the paper core winding in solid, winding the resin fast in order; good permeability; the fabric made of laminated material of dry, wet mechanical strength shall meet the requirements.The paving composites are characterized by low interlaminar shear strength, poor compressive strength and fatigue strength. (1) chopped strand glass raw silk (sometimes with roving) cut into 50mm long, but it will be randomly evenly Chen on the mesh belt, then put on powder or emulsion binder spreading agent bonded into CSM by heating after curing. Short cut felt is mainly used for hand finishing, continuous plate making and die pressing and SMC process. The quality of CSM requirements are as follows: uniformly along the width direction of the quality area; the chopped strand mat surface in uniform distribution, no hole formation, binder distribution; with moderate strength, excellent dry mat; resin infiltration and permeability.

- Q:The costs of posting mesh are reasonable?

- It is mentioned to stick mesh in the construction technology which is included in the unit price. But in the process of construction, the foreman insisted on separate charge for the cost of the mesh, this is reasonable? T The process content in the Contract is as follows : 1: cleaning brush metope beauty solid nest wall again, 2: the nest bottom paint plaster leveling, 3: brush the nest wall fixed grid cloth, 4: the nest easily shave - 400, 2-3 times, 200 - watt bulb light and grinding smooth, brush primers, 5: Excluding special wall treatment, such as required gray sand leveling, the cost of another 15 yuan per square meter. 6: This offer provides paint, roller, brush wool and other disposable utensils from Party A. 7: To paint additive color is no more than two colors, one color for each additional should plus $ 150.

- Q:How to distinguish warp?and?weft of alkali-resistant fiberglass mesh?

- The two strands of small wire is warp, and the thicker one is weft. While being used, take warp as a horizontal position.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

FRP Surfacing Mat- high qulity, low price

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords