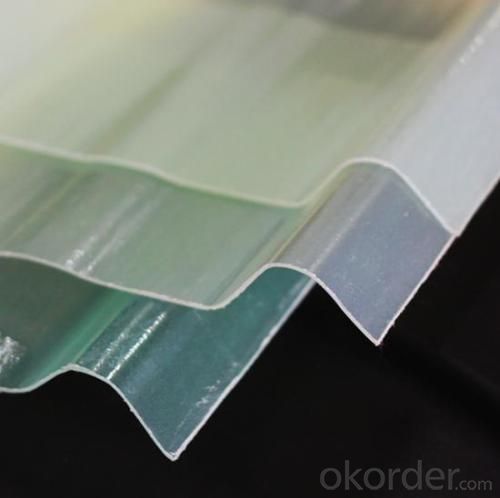

FRP Roofing Panel Colorful Roofing Metal Sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m

- Supply Capability:

- 20000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

PRODUCT DESCRIPTION

Fiberglass corrugated sheet is usually used in construction site as protecting facility. It is dagarous for workers in building site since you never know if there is something hard drop down from the high area. So corrugated sheet is installed for preventing the stuff dropping down to hurt people.

FEATURES

1) The fiberglass content of new generation greenhouse panel has been improved by 18.3%.

2) Weather resistant and Self-clean ability.

3) Excellent yellowness resistance.

4) Strong impact resistant and low bending rate.

5)Withstand extreme temperature from -38 degree to +110 degree for a long time

6) Aging resistant: specified F4 film added on surface and gel coat makes it endurable for long.

7) More strengthened, safer, cleaner and more economical greenhouse panel.

8) Mainly serve the big factory, warehouse, super markets and other steel-structured project.

SPECIFICATIONS

| Items | Date |

| Tensile Strength | 122.8Mpa |

| Tensile Modulus | 8610Mpa |

| Flexural Strength | 219.9mPA |

| Flexural Modulus | 8210Mpa |

| Barcol Hardness | 47 |

| Izod Impact | 80.4kj/m2 |

| Thermal Expansivity | 2.4X10-5 °C-1 |

| Distortion Termperature | >230°C |

| Water Absorption | 0.16%/24hrs@25°C |

| Gravity | 1.5g/cm3-1.9g/cm3 |

PICTURES

- Q:Can FRP roofing panels be recycled?

- Yes, FRP roofing panels can be recycled. FRP stands for Fiberglass Reinforced Plastic, which is a composite material made of glass fibers and resin. It is commonly used in roofing due to its durability and resistance to various weather conditions. When these panels reach the end of their life cycle, they can be recycled by removing the fiberglass fibers from the resin matrix. The fibers can then be reused in various applications, while the resin can be processed and used as a fuel source or for other purposes. Recycling FRP roofing panels helps reduce waste and supports sustainable practices in construction.

- Q:Can FRP roofing panels be used for outdoor structures?

- Yes, FRP (Fiber Reinforced Plastic) roofing panels can be used for outdoor structures. FRP roofing panels are known for their durability, strength, and resistance to weather elements such as UV rays, rain, and wind. These panels are designed to withstand harsh outdoor conditions and provide excellent protection for various structures. They are commonly used for outdoor applications such as patios, pergolas, carports, sheds, and agricultural buildings. In addition to their weather resistance, FRP roofing panels are also lightweight, easy to install, and have a long lifespan. Overall, FRP roofing panels are a reliable and practical choice for outdoor structures.

- Q:Can FRP roofing panels be used in mobile homes?

- Indeed, mobile homes can utilize FRP (Fiberglass Reinforced Plastic) roofing panels. These panels possess the qualities of being lightweight, durable, and highly resistant to weathering and UV radiation, rendering them appropriate for various applications, including roofing. They present a cost-effective alternative to conventional roofing materials and offer commendable insulation properties. Moreover, the installation of FRP panels is trouble-free, and their maintenance requirements are minimal, making them an optimal choice for mobile homes that prioritize mobility and convenience. Nevertheless, it is crucial to verify that the mobile home's structure is compatible with the installation of FRP roofing panels and to take all necessary precautions during installation to ensure adequate sealing and waterproofing.

- Q:Are FRP roofing panels resistant to impact damage from falling debris?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels are generally resistant to impact damage from falling debris. FRP panels are manufactured using a combination of fiberglass and plastic resin, which makes them strong and durable. They are designed to withstand various weather conditions and are known for their impact resistance. This makes them suitable for areas where there is a risk of falling debris, such as in industrial or construction sites. However, it is important to note that the level of impact resistance can vary depending on the specific brand and quality of the FRP roofing panels. It is always recommended to consult with the manufacturer or a roofing professional to ensure that the chosen FRP panels are suitable for the specific application and expected impact loads.

- Q:Can FRP roofing panels be used in curved or sloped roofs?

- Curved or sloped roofs can indeed accommodate FRP (Fiberglass Reinforced Plastic) roofing panels. These panels possess flexibility and can be effortlessly curved to align with the structure of such roofs. They are engineered to handle diverse angles and shapes, thereby rendering them a versatile choice for a range of roof designs. Moreover, FRP panels are lightweight, long-lasting, and resilient against weathering, making them an apt option for deployment in various roof types, including curved or sloped ones.

- Q:Are FRP roofing panels prone to discoloration over time?

- FRP (Fiberglass Reinforced Plastic) roofing panels are generally not prone to discoloration over time. These panels are known for their excellent resistance to UV rays, which helps prevent fading or yellowing that can occur with other materials. However, it is important to note that the extent of discoloration also depends on the quality of the FRP panels and the environment in which they are installed. If the panels are of low quality or exposed to harsh weather conditions, such as extreme heat or excessive moisture, there is a possibility of some discoloration occurring over an extended period of time. To minimize the risk of discoloration, it is recommended to choose high-quality FRP roofing panels and properly maintain and clean them regularly.

- Q:Are FRP roofing panels prone to discoloration over time?

- FRP (Fiberglass Reinforced Plastic) roofing panels are generally not prone to discoloration over time. These panels are known for their excellent resistance to UV rays, which helps prevent fading or yellowing that can occur with other materials. However, it is important to note that the extent of discoloration also depends on the quality of the FRP panels and the environment in which they are installed. If the panels are of low quality or exposed to harsh weather conditions, such as extreme heat or excessive moisture, there is a possibility of some discoloration occurring over an extended period of time. To minimize the risk of discoloration, it is recommended to choose high-quality FRP roofing panels and properly maintain and clean them regularly.

- Q:Can FRP roofing panels be used for bus shelters?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be used for bus shelters. FRP roofing panels are commonly used in various architectural applications due to their durability, lightweight nature, and resistance to weather elements such as UV radiation, rain, and snow. These panels are also known for their excellent insulation properties, which can help maintain a comfortable temperature inside the bus shelter. Additionally, FRP roofing panels can be easily installed and require minimal maintenance, making them a suitable choice for bus shelters that need to withstand frequent use and exposure to outdoor conditions.

- Q:Do FRP roofing panels require any special certifications or approvals?

- Yes, FRP roofing panels typically require special certifications or approvals depending on the specific building codes and regulations in each region. These certifications ensure that the panels meet certain safety standards and performance criteria, providing assurance to customers and authorities that they can be used in construction projects. It is advisable to consult local authorities or building professionals to determine the specific certifications and approvals required for FRP roofing panels in a particular area.

- Q:Can FRP roofing panels be used for skylights or translucent roofing applications?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can indeed be used for skylights or translucent roofing applications. FRP panels are known for their durability, strength, and resistance to weathering, making them a suitable choice for such applications. Their translucency allows natural light to filter through, creating a bright and well-lit space underneath. Additionally, FRP panels are lightweight and easy to install, making them an efficient choice for skylights or translucent roofing.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

FRP Roofing Panel Colorful Roofing Metal Sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m

- Supply Capability:

- 20000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords