FRP Rods, Top Quality Fiberglass Rod/ FRP Profiles Tube

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m

- Supply Capability:

- 50000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of FRP Rod Description

We produce varity fiberglass products . like tent pole , pultruded handles and all kinds of garden tools, Plant supports , Greenhouse and so on . At present, it is a trend to use the fiberglass handle as gardening tools, it is a new type of handle and will replace the wood handle,iron handle and aluminum handle step by step.

Wood handle is apt to corrode, iron handle is ADP to rust and aluminum handle is apt to oxidate, while fiberglass handle is the combination of resin and fiberglass,it is corrosion resistant and anti-aging.

2. Main Features of FRP Rod

1) Low Density: 67%~74% of aluminum

2) High Strength, Tenacity, and Modulus

3) High Corrosion Resistance

4) UV Resistance

5) Electromagnetic Transparency

6) Electrical & Thermal Non-Conductivity

7) Dimensional Stability

8) Applicability under Wide Temperature Range

3. FRP Rod Images

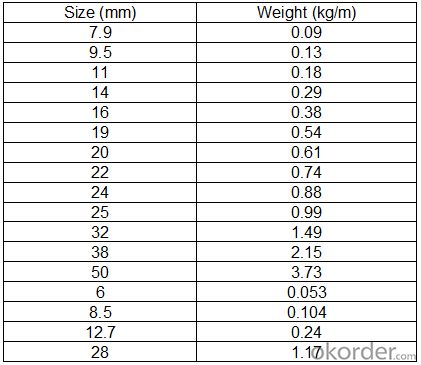

4. FRP Rod Specification

5. FAQ of FRP Rod

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

One of the leading manufacturers and suppliers specializing in FRP products in China. The integrated sales & service ensures customers with various demands an easier access for purchasing management.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible.

- Q:Are there any differences between FRP pipes and FRP pipes?

- Air duct is a pipe system used for air transportation and distribution. There are two kinds of composite air duct and inorganic air duct. The duct can be classified according to the shape and material of the section. Duct made of stainless steel duct, in the bite mouth, rivet joint, flange, four corners and other cracks painted with sealant (such as neutral glass glue). Surface dust and grease shall be removed before applying sealant. According to the section shape, the wind pipe can be divided into circular duct, rectangular duct, a variety of flat air pipe, wherein the circular duct resistance minimum maximum height, making complex. Therefore, the application of rectangular wind tube based. According to the material, the air duct can be divided into metal wind pipe, composite air pipe and macromolecule air pipe.

- Q:Glass fiber reinforced plastic sand pipe backfill 5m, how much kg pressure?

- You don't even know the pressure inside.

- Q:FRP pipe price

- The price range of raw material resin is about 10000/ tons to 60000/ tons.

- Q:How to prevent the glass fiber reinforced plastic pipe from being damaged by aging or over pressure, causing the liquid to splash and hurt people

- If you are afraid of the glass tube will be such a question, the weak links or parts of the local reinforcement, the conditions can, can re pipe liner, to compression, anti ageing effect

- Q:How much is a glass fiber reinforced plastic sand pipe socket pipe fitting?

- Compared with the traditional pipe, it has excellent chemical resistance. It can resist acid, alkali, salt, oxidant, organic solvent, various kinds of grease, sewage and so on. Its lining is made of corrosion resistant and excellent resin as raw material, so no corrosion protection is needed. And after long-term use, no fouling, will not be contaminated by micro-organisms and debris deposition in the sewage, so as to increase the roughness rate and reduce the water cross section or plug the pipeline. Because the damage rate of glass fiber reinforced sand pipe is more than 4 times the working pressure, the safety factor is designed with enough safety factor.

- Q:What epoxy resin is used for anticorrosion of pipeline glass fiber reinforced plastics?

- 3PE has been anti-corrosion principle, there is no need for anti-corrosion, but now the domestic situation. Directional drilling pipe cannot be detected and repaired, the anticorrosion layer cannot have serious damage to the pipeline, long-term safety operation, it should be required for coating directional drilling: scratch resistance, abrasion resistance, impact resistance, high hardness, strong adhesion and pipeline, corrosion resistance, water resistance have a good soak, matching and cathodic protection system.

- Q:Winding method of glass fibre reinforced plastic pipeline anticorrosive glass fiber cloth

- 1) FRP reinforcement, length of rectangular duct is greater than 900mm, and the pipe length is more than 1250mm, should be strengthened. The reinforcement shall be made of bulk material (fiber reinforced plastic) and reinforced plate at the maximum stress, so as to increase the modulus of the section and increase the overall strength of the tube. FRP reinforcement can also be in the wind pipe production is completed, the treated metal or other corrosion resistant material for reinforcement, reinforcement and FRP as a whole, and with the same pipeline body cementitious material sealing gap2) hobas pipe surface thickness of the slurry to flatten the glass fiber mesh cloth texture is appropriate (see:). No dense air holes and grout leaks are allowed on the wall of the pipe to avoid the stress concentration under the bending tensile stress (positive air pressure) and the bending compressive stress (negative wind pressure).3) FRP pipe and flange corner should transition arc, transition radius to wall thickness of 0.8 ~ 1.2 times, improve the bearing capacity and the cantilever flange to avoid stress concentration. Fiberglass mesh shall be extended to the duct at the flange of the duct.

- Q:Which is better, PVC pipe and GRP pipe?!

- To see the composition of your gas, fiberglass can be chosen according to the requirements of different resins for corrosion protection, and PVC for some gases are not corrosion-resistant,

- Q:What are the materials used in smoke exhaust pipes?

- In the production of the coal mine exhaust pipe is indispensable, in underground work, because from the ground, the air is not easy to reach, easy to accumulate large amounts of methane gas, these gases will need ventilation pipe timely transferred to the ground to prevent the explosion in the coal mine ventilation pipe, the material is generally iron and plastic.

- Q:Is it possible to touch the water when the glass fiber reinforced plastic pipe is polished?

- Because the resin curing mechanism of FRP products is resin, resin agent, resin curing agent together to react, and release a lot of heat, this process does not affect the curing process because of a small amount of water and at the same time, if you have a little bit of water molecules would because of the large amount of heat emitted by evaporate, so does not affect the bonding of glass and steel that will not affect the glass steel pipe interface

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

FRP Rods, Top Quality Fiberglass Rod/ FRP Profiles Tube

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m

- Supply Capability:

- 50000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords