FRP Pultrusion Profilefor Door and Window

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m

- Supply Capability:

- 10000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

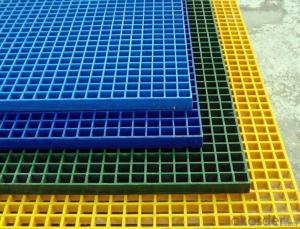

Pultrusion process is a mechanized process for FRP composites involves pulling a collection of fibers in the form of roving mat or fabric through a resin bath and then through a heated die to cure the resin, and then take shapes of profiles. FRP pultruded profiles are more than a kind of structure, which is very designable. Changing the choice of the materials and designs of the lamination process can make special properties for it.

Product Performance:

• Corrosion resistant and anti-ageing

• Water-proof, fire retardant, Heat Resistance

• Very designable, cut discretionarily

• Easy of installation and dimensional stability

• Bright color and good appearance

PROFILE TYPE

By changing different shapes of the mould (die), this production line can produce different profiles or rods.

Application

The FRP channel products can resist corrosion from various gas or liquid such as acid,alkali,organic solvent and compound.They can be used as ladder material,and used in the electricity industries. It can be widely use in railing, bracket of water circulation tower, sport equipment, tool handle, bracket of tent and others loading structure components

FAQ:

1.Who will pay for the express cost ?

A: We can support you free samples ,but express cost will be paid by you .

2.How long is the delivery time?

A:within 10-15 days after receiving deposit.

- Q:I bought a coat off of Ebay and it smells terrible, ,its dirty too it has wood chips on it. The coat is from Old Navy and is made out of 40% Recycled Wool 24% Acrylic 22% polyester 10% nylon (shell) the inside is 100% polyester. It is a peacoat, knee length

- I washed my wool coat in cold water, I put it in the dryer for three minutes, just to try to get it wrinkle-free. I then hung it from the shower rod curtain, it did not shrink and came out fine, however, if you absolutely cannot take the chance that it will shrink then you will have to send it to the cleaners

- Q:I don‘t know were to get it or the name of the right fiber glass i need.

- Fiberglass is glass fiber cloth with polyester or epoxy resin filling and coating it. You want a woven roving or weave and the resin to apply to it. You can go to any boating store or look one up. It is not easy to work with and boats are made in a smooth mold with colored resin applied first, then layers of resins saturated cloth. If you do not use a mold a tremendous amount of sanding is needed so that is looks acceptable. Wood is very fine for speakers, easy to work with and make changes. It is also less expensive, cleaner, and can be stained, painted, or cloth covered. It will also sound better.

- Q:cloths were made of in the 1945‘s, i was just watching The Spanish Main with Maureen OHara, and her cloths are beautiful, these days seems i can‘t find really cool cloths made from cotton, the pretty designs are rayon or polyester , i wish more were made with natural cotton, but would anyone know what the cloths were made of in those days 1945 ish ?

- 1st of all CHECK THE FUSE!!!

- Q:kill your wife because she wore Cotton and Polyester at the same time and a bunch of other thingseach time it shows the quote in the bible where each thing we COMMONLY do now is punishable usually by death according to the Bible thanks it was hilarious and I want it.

- So, what's wrong with cotton and polyester? I'm confused, but yet, the bible is confusing. Oh, do not work on the Sabbath day! You shall be put to death!

- Q:Whats the cloth on swimwear and why is it in swimwear?

- For the best answers, search on this site shorturl.im/axfsn not sure what the r or 925 mean but cz means cubic zerconia.

- Q:I have a thin coat I have to wear to work as a waitress and it always smells funny. I can‘t describe the smell exactly, all I know is that it smells weird (stale, maybe?) and I can‘t get rid of it no matter how much I wash it. It worsens after each work day and I think it‘s a combination of food particles in the cloth and just the fabric itself. It looks homemade (no tag) and feels like a polyester/rayon type cloth. I wash it in cold water with powder detergent every night and dry it on Medium heat.Please tell me there‘s something I can do to change/get rid of the way this thing smells. Something to soak it in? A new way of washing it? Anything?

- well, coppers usually dont pack any heat unless they are trained to use a gun, so they dont have a gun off duty. but they do use their warrant card as ID.

- Q:I can not find the PUL anywhere-but someone told me to try 100% polyester and to wet and dry b4 sewing-supposedly all the fibers are supposed to melt together causing a waterproofing-has anyone tryed this??any ideas for patterns or materials other than that?

- you are crazyyyyyyyyyyyyyyyyyyyyyyy! yeah!!!!!!!!!!!!!!!!!!!!!!!!!!

- Q:I recently ordered a jacket off of the internet and when it came, It had a ball point pen mark on it. I really like it and don‘t want to return it. It says that it is 100% polyester all over. I have tried wiping it with a white cloth, like it says, rubbing alchohal, like my mom suggested, and a product called Goof Off, none of which had any effect. I don‘t want to bleach it because it has some green, and it isn‘t supposed to be washed either. What do I do?

- Spray the ink mark with hairspray, really saturate it. But be careful to place some plastic or wax paper beneath the fabric so it doesn't just bleed through to another layer. Let it soak for several minutes, then wash it. If some ink still shows, do NOT dry it yet! Treat it again, wash it again, and don't dry it until the stain is gone. Works every time.

- Q:I have a client with a black grand piano. Most piano‘s I clean I use water and polish with a microfiber cloth since the finish can‘t handle most products.Well, this household loves it‘s fried food and there is a layer of grease or some kind of film that won‘t come off with just water. I can‘t afford to ruin the finish, but it needs to be cleaned. What would you recommend I use to get this film off?Thanks!

- I suggest you get Old English wood cleaner, and try it out first on an inconspicuous spot -- such as the inside top of a leg. I have used Old English on many pieces of antique furniture with great success, but you MUST follow the instructions carefully!

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

FRP Pultrusion Profilefor Door and Window

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m

- Supply Capability:

- 10000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords