FRP Pultrusion Profile Cable Tray with High Quality

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m

- Supply Capability:

- 100000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Pultrusion process is a mechanized process for FRP composites involves pulling a collection of fibers in the form of roving mat or fabric through a resin bath and then through a heated die to cure the resin, and then take shapes of profiles. FRP pultruded profiles are more than a kind of structure, which is very designable. Changing the choice of the materials and designs of the lamination process can make special properties for it. It can be widely use in railing, bracket of water circulation tower, sport equipment, tool handle, bracket of tent and others loading structure components

Product features :

• Corrosion resistant and anti-ageing

• Water-proof, fire retardant, Heat Resistance

• Light weight, high strength and impact strength

• Non-magnetism and non-conductive

• Very designable, cut discretionarily

• Easy of installation and dimensional stability

• Long service life and maintenance-free

• Bright color and good appearance

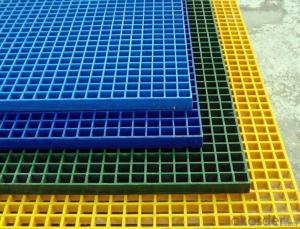

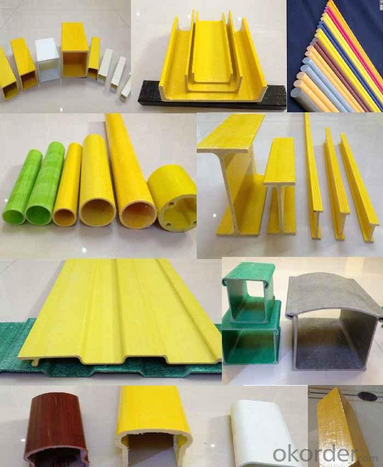

PROFILE TYPE

By changing different shapes of the mould (die), this production line can produce different profiles or rods. The following list is some products photos for reference.

No. | Item | No. | Item |

1 | Rectangular tube | 9 | Cable tray |

2 | Square tube | 10 | Handrail |

3 | Round tube | 11 | Profile for door & window |

4 | Channel | 12 | Guardrail |

5 | I-beam | 13 | End fitting of Radome |

6 | Angel | 14 | Shaft of the umbrella& tent |

7 | Epoxy rod | 15 | Profile for bridge |

8 | Platform and ladder | 16 | Ladder |

product Specifications :

Round Rod: D2mm-20mm

Round Tube: OD3mm-38mm

Square Tube: OD12mm-100mm

Channel Rectangular Rod

T-shape and H-shape

C-shape

leg angles

Application

The FRP channel products can resist corrosion from various gas or liquid such as acid,alkali,organic solvent and compound.

They can be used as ladder material,and used in the electricity industries.

FAQ:

1.Who will pay for the express cost ?

A: We can support you free samples ,but express cost will be paid by you .

2.How long is the delivery time?

A:within 10-15 days after receiving deposit.

- Q:My son bought a nice Chicago Bulls jacket off another kid, cheap ($50). It‘s in very good condition, a few years old, perfect color, but it‘s slightly dirty. It‘s cloth, with no tag indicating material type. I think it‘s an XXL, thick,100% cotton shell, with a polyester lining. It has a lot of nice embroidered lettering and logos on the front, back and on the sleeves. It looks like about a $150 to $200 jacket. It‘s not heavily soiled at all. How much would it cost to dry clean? I‘m a blue collar type guy and I haven‘t owned a sport coat in over ten years. My ex wife would have a couple of my jackets cleaned with her stuff and I never really knew how much she spent. She couldn‘t even run to Target for some make-up or a couple houseplants, without spending $100 dollars, so I stopped asking how much some things cost. I used to call every place she shopped the Hundred Dollar Store. Ha ha! I told my son it might cost him $10 to $20, but I have no clue. It is absolutely not suede or leather, satin or velvet

- simply do what i did.buy a bike[scrapper],get a matching manual.read it.understand how it works and what bit does what.then strip the engine and rebuild itif it starts and runs,then youve got itsimple as that,you cant beat hands on.enjoy.

- Q:My future wife is looking to buy a weeding gown but she was curious to find out if satin is actually classified into different types or maybe the quality.

- put the key in the ignition and turn it to the on position. that will disengage the anfi-theft steering lock and allow you to turn the wheel at will

- Q:What is the suede low iron tempered glass?

- Glass has a hard and brittle, has a good transparency and high temperature resistance, corrosion resistance and other properties; at the same time, steel is very hard and not brittle, but also has high temperature resistance characteristics. So people began to think, if you can make a kind of glass has both hardness, high temperature resistance, corrosion resistance of the nature, but also with steel as hard, not broken characteristics, then this material will be of great use.

- Q:How to choose high quality fiberglass polyester cable trough?

- High quality products have the characteristics of light weight, easy installation and transportation, strong impact resistance, corrosion resistance, flame retardant, insulation, long service life and so on.

- Q:It‘s something about their outfits.

- Wish people knew the difference between a Nun and a Sister. Nun?s are Cloistered, You never see one. Sisters are the religious you see in schools or hospitals. Nun?s are contemplative and take Solemn vows, whereas Sisters take mixed vows, solemn or simple vows, depending upon their affiliation, Dominicans, Franciscans take two sets of simple vows of three years then profess their solemn perpetual vows. Others who belong to societies take simple vows. Mr. Byrd I find your question offensive. I chalk it up to ignorance.

- Q:I‘m at work right now, and my dress is just clinging to me! Any ideas how to get rid of it?

- Remove Static Electricity From Clothes

- Q:How to identify the good or bad of glass fiber

- Do not test so many things, as long as open to see the inside of the glass fiber appearance, there is no fluff, stains or concave convex deformation can be, in general these three no problem, you can rest assured that the use of

- Q:I have a taffeta/polyester bridesmaid dress with several obvious creases in it. Can I remove them by steaming it? I am afraid to iron it.

- Try lubricating the sliding calipher. Just take out the bolt that holds the calipher in place, put some wheel bearing grease on it then put it back in. Put a small ammount of grease on the bottom of the calipher where it slides.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

FRP Pultrusion Profile Cable Tray with High Quality

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m

- Supply Capability:

- 100000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords