FRP Pultruded Grating Easy of maintenance on sales

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4000 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

PRODUCT DESCRIPTION

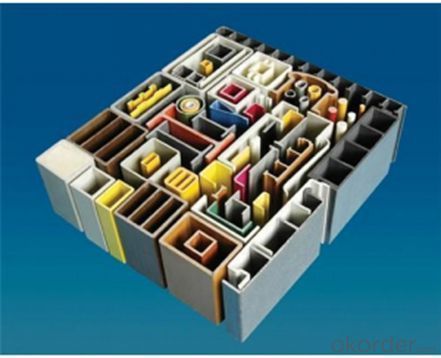

Pultruded grating is made by a par ticular assembly process, which using “I” shape as its main load-bearing and special rod to go through the bearing bar. Pultruded grating include the standard grating and the custom grating, the custom grating can be designed to meet customer’s requirement or special using condition by changing the shape, size and space of the bearing bars, the sur face can be covered with lozenge panel, grit panel, or added the anti-slippery sand directly.

FRP pultruded grating has the most characteristics of molded grating, but it has its distinct advantages, it has very high fiberglass content in the loading direction, so it has very high load capability, it has more superiority when used at wide span, so that the basic support will be decreased and the project cost will be reduced accordingly.

SPECIFICATION

The standard space between two crossbars is 6 inch or 12 inch.

Thickness (mm) | Bar width (mm) | Open space (mm) | Open rate (%) | Approx weight (kg/m |

25.4 | 15.2 | 22.8 | 60 | 13.2 |

25.4 | 15.2 | 15.2 | 50 | 15.9 |

25.4 | 15.2 | 10.1 | 40 | 18.5 |

25.4 | 40 | 10.8 | 21 | 14.5 |

38.1 | 15.2 | 22.8 | 60 | 15.8 |

38.1 | 15.2 | 15.2 | 50 | 19.1 |

FEATURES

a. Anti-corrosion and anti-rust

b. Light weight and high strength

c. Anti-flammable

d. Anti- fatigue

e. Safe and anti-slippery

f. Anti-ageing

g. Easy of maintenance

h. Excellent electromagnetism property

i. Good economic benefit

FIELDS SERVED

Sewage treatment,

water supply and drainage,

chemical industry,

oil industry,

power engineering,

APPLICATION

Operation terrace,

stair walkway,

ground floor,

trench cover,

sidewalk,

foot bridge,

equipment safety fence,

scaffold.

COMPANT DESCRIPTION

CNBM,China National Building Materials Group is a state-owned enterprise in charge of administrative affairs in china building materials industry. Established in 1984, CNBM is a large group corporation of building materials with total assets of 25 billion RMB and a total staff of 30,000.CNBM now owns 200 subordinating firms of solely owned and joint-venture companies.

CNBM International Corporation is one subsidiary of CNBM, we focus on offering good-quality products,professional service and complete solution to our customers. Strong delivery capacity, advanced technology& management, strong financing capability and excellent after-sale service are our advantages in sharing international market.

PACKAGING & DELIVERY

1.PACKAGING DETAILS:

standard packing or your requirement

2.DELIVERY DETAIL:

Shipped in 30 days after payment

FAQ

1.Q:Are you factory or trading company ?

A:We are Factory produce FRP machines and FRP products.

2.Q:If can customized by customers requirements?

A:yes,we can produce the machine with customized size.

3.Q:How about the payment?

A:We accept any kind of payment.

4.Q:What is the guarantee?

A:Gurantee is one year.

5.Q:If you can training?

A:yes ,we can training in our factory also can send engineers to your factory training.

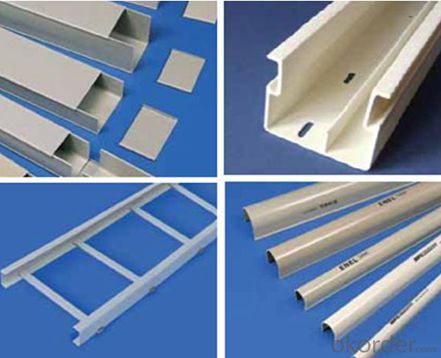

PICTURES

- Q:What are the environmental benefits of using FRP pultrusion profiles?

- Using FRP (Fiber Reinforced Polymer) pultrusion profiles offers several environmental advantages. To begin with, FRP pultrusion profiles are lightweight and possess a high strength-to-weight ratio. This means that less material is needed to achieve the same structural integrity as traditional materials like steel or concrete. Consequently, the production and transportation of FRP profiles consume less energy and result in fewer greenhouse gas emissions. Additionally, FRP pultrusion profiles exhibit exceptional durability and resistance to corrosion. This extends their lifespan and reduces the frequency of replacements required. As a result, resources are conserved, and the amount of waste ending up in landfills or requiring recycling is reduced. Moreover, FRP is non-conductive, making it an excellent alternative to metals in electrical applications. This property eliminates the risk of electrical accidents and decreases the necessity for insulation, which often involves hazardous substances. Furthermore, the manufacturing process of FRP pultrusion profiles generally requires lower energy inputs compared to other materials. The pultrusion process itself is energy-efficient, and the raw materials used in FRP production, such as resins and fibers, can be obtained from renewable or recycled sources. Lastly, FRP pultrusion profiles are chemically inert and do not release harmful substances into the environment. This characteristic makes them suitable for various applications, including water treatment plants, where preventing chemical leaching is crucial for maintaining water quality. In conclusion, the use of FRP pultrusion profiles brings about environmental benefits such as reduced energy consumption, lower greenhouse gas emissions, prolonged product lifespan, decreased waste generation, reduced dependence on non-renewable resources, and minimized chemical leaching. These advantages establish FRP as a sustainable and eco-friendly choice for a wide array of industries.

- Q:Are FRP pultrusion profiles resistant to alkaline substances?

- Yes, FRP pultrusion profiles are generally resistant to alkaline substances. The use of fiberglass reinforced polymer (FRP) in pultruded profiles provides excellent resistance to a wide range of chemicals, including alkaline substances. The resin used in the manufacturing process is typically a thermosetting polymer, such as polyester or vinyl ester, which offers high resistance to alkaline solutions. Moreover, the reinforcement of fiberglass imparts additional strength and durability to the profiles, making them highly resistant to corrosion and degradation from alkaline substances. However, it is important to note that the specific resistance of FRP pultrusion profiles to alkaline substances may vary depending on the specific resin formulation and manufacturing process. Therefore, it is recommended to consult with the manufacturer or supplier to ensure the profiles meet the desired resistance requirements for specific alkaline environments.

- Q:Are FRP pultrusion profiles resistant to graffiti?

- Due to their unique characteristics and composition, FRP pultrusion profiles generally exhibit resistance to graffiti. These profiles, made from a combination of high-strength fibers and a polymer resin matrix, yield a material that is highly durable and robust. An important advantage of FRP profiles is their exceptional resistance to various forms of corrosion, including chemical, moisture, and UV resistance. As a result, FRP profiles are less vulnerable to the detrimental effects of graffiti. Unlike traditional materials like wood or metal, FRP pultrusion profiles lack a porous surface that permits easy penetration and adhesion of paint or markers. Furthermore, FRP profiles are often manufactured with a smooth and non-porous finish, which further discourages graffiti attachment. Even if graffiti is applied to the surface, it can be effortlessly removed using non-abrasive cleaning methods without causing any harm to the profile's structural integrity or appearance. Nevertheless, it is important to acknowledge that no material is entirely impervious to graffiti. Determined vandals may still discover methods to leave marks on FRP profiles by employing specialized graffiti materials or techniques. Nevertheless, the resistance of FRP pultrusion profiles to graffiti is significantly higher compared to numerous other traditional materials, making them an ideal choice for areas that are prone to vandalism or graffiti attacks.

- Q:Can FRP pultrusion profiles be used in infrastructure projects?

- Yes, FRP pultrusion profiles can be used in infrastructure projects. These profiles are lightweight, durable, and corrosion-resistant, making them ideal for applications in bridges, walkways, railings, and other structural components. They offer high strength-to-weight ratios and can be customized to meet specific project requirements. Additionally, FRP pultrusion profiles are non-conductive, making them suitable for electrical infrastructure projects.

- Q:Are FRP pultrusion profiles resistant to moisture?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles are highly resistant to moisture. The manufacturing process of FRP pultrusion involves impregnating fiberglass reinforcements with a resin matrix, typically polyester, vinyl ester, or epoxy. These resins are inherently moisture-resistant, making FRP pultrusion profiles suitable for various applications that involve exposure to moisture or humid environments. Unlike traditional materials like wood or steel, FRP does not absorb water, which eliminates the risk of swelling, warping, or corrosion. This moisture resistance is particularly advantageous in applications such as construction, infrastructure, and marine industries, where the profiles may be exposed to rain, saltwater, or high humidity. Additionally, the resin matrix used in FRP pultrusion can be further enhanced with additives or coatings to provide even greater moisture resistance. For example, UV inhibitors can be added to protect against degradation caused by sunlight exposure. Fire-retardant coatings may also be applied to meet specific safety requirements. Overall, FRP pultrusion profiles offer excellent resistance to moisture, making them a durable and reliable choice for various applications where moisture exposure is a concern.

- Q:Are FRP pultrusion profiles resistant to humidity or moisture?

- Yes, FRP pultrusion profiles are highly resistant to humidity or moisture due to their non-porous nature and the use of corrosion-resistant materials.

- Q:How do FRP pultrusion profiles compare to steel or aluminum profiles?

- FRP (Fiber Reinforced Polymer) pultrusion profiles offer several advantages over steel or aluminum profiles. Firstly, FRP profiles are extremely lightweight, making them easier to handle and install. This is particularly beneficial in industries where weight reduction is crucial, such as aerospace or automotive applications. Another significant advantage of FRP pultrusion profiles is their exceptional corrosion resistance. Unlike steel or aluminum, FRP does not rust or corrode when exposed to moisture, chemicals, or harsh environmental conditions. This property makes FRP profiles ideal for applications in marine environments or chemical processing plants, where traditional materials would quickly deteriorate. In terms of strength, FRP pultrusion profiles can match or even surpass steel or aluminum profiles. The unique combination of reinforcing fibers and polymer resin in FRP provides excellent tensile and flexural strength. Additionally, FRP profiles have a high stiffness-to-weight ratio, meaning they can withstand heavy loads while remaining lightweight. Furthermore, FRP pultrusion profiles offer excellent electrical insulation properties. Unlike metal profiles, FRP does not conduct electricity, making it a safe choice for electrical applications where insulation is crucial. While steel or aluminum profiles may have their own advantages in certain applications, FRP pultrusion profiles often provide a more cost-effective solution due to their long lifespan and low maintenance requirements. FRP profiles are not susceptible to rust, corrosion, or degradation, minimizing the need for frequent repairs or replacements. Overall, FRP pultrusion profiles offer a compelling alternative to steel or aluminum profiles, providing lightweight, corrosion-resistant, strong, and electrically insulating solutions for various industries and applications.

- Q:Plastic or better glass fiber reinforced plastic better?

- Glass fiber reinforced plastics, usually glass fiber reinforced unsaturated polyester, epoxy resin and phenolic resin matrix. Because of the different kinds of resins used, they are called polyester glass fiber reinforced plastics, epoxy glass fiber reinforced plastics and phenolic resin glass fiber reinforced plastics. Its characteristics are: light and hard, non conductive, stable performance, high mechanical strength, less recycling and corrosion resistance. It can be used instead of steel to make machine parts, automobiles, ship shells, etc..

- Q:What is the cost of FRP pultrusion profiles compared to other materials?

- The cost of FRP (Fiber Reinforced Polymer) pultrusion profiles can vary depending on several factors such as the specific application, size, complexity of design, and quantity required. However, in general, FRP pultrusion profiles tend to be more cost-effective compared to many traditional materials. When compared to materials like steel, aluminum, or wood, FRP pultrusion profiles often provide a lower overall cost, especially when considering long-term savings. While the initial material cost of FRP pultrusion profiles may be slightly higher than some traditional materials, the benefits and advantages it offers can outweigh the price difference. FRP pultrusion profiles are known for their lightweight nature, high strength-to-weight ratio, corrosion resistance, and durability. These characteristics contribute to reducing transportation costs, installation expenses, and maintenance requirements. Additionally, the long lifespan of FRP profiles ensures minimal replacement or repair costs over time. Moreover, the manufacturing process of FRP pultrusion profiles allows for precise customization, eliminating the need for additional machining or fabrication, which can further reduce costs. The ability to incorporate design features such as integral stiffeners, brackets, and fastening points during the pultrusion process eliminates the need for additional assembly steps, ultimately saving time and money. It is important to note that while FRP pultrusion profiles may have a higher upfront cost compared to some materials, the overall cost-effectiveness and long-term benefits make them a favorable choice in many applications. Each project's specific requirements and considerations should be taken into account when evaluating the cost of FRP pultrusion profiles compared to other materials.

- Q:Can FRP pultrusion profiles be used in the construction of wastewater treatment tanks?

- Indeed, wastewater treatment tanks can effectively utilize FRP pultrusion profiles. These profiles are renowned for their exceptional strength-to-weight ratio, resistance to corrosion, and longevity, making them an optimal option for harsh environments such as wastewater treatment facilities. To manufacture FRP pultrusion profiles, continuous fibers like glass or carbon are drawn through a resin bath and subsequently through a heated die to attain the desired shape. This process yields profiles with consistent cross-sections and outstanding mechanical properties. In the construction of wastewater treatment tanks, FRP pultrusion profiles can serve various purposes. They can function as structural components, like beams, columns, and bracing systems, offering the necessary strength and rigidity to support the tank structure. Additionally, FRP profiles can reinforce concrete structures, bolstering their durability and resistance against chemical attack from the wastewater. Moreover, FRP pultrusion profiles can be engineered to endure the corrosive impact of the chemicals and gases found in wastewater treatment tanks. Unlike conventional materials such as steel or concrete, FRP exhibits a high resistance to corrosion, guaranteeing an extended service life and reduced maintenance expenses. Furthermore, FRP profiles provide advantages in terms of installation and transportation. They are lightweight, enabling easier handling and diminished labor requirements during construction. The modular nature of FRP profiles also facilitates swift assembly and disassembly, simplifying maintenance and modifications. Overall, incorporating FRP pultrusion profiles in the construction of wastewater treatment tanks offers numerous benefits, including superior strength, corrosion resistance, durability, and ease of installation. These advantages render FRP a dependable and cost-effective choice for wastewater treatment facilities.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

FRP Pultruded Grating Easy of maintenance on sales

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4000 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords