FRP Molded Grating /GRP Grating / FRP Grating

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction

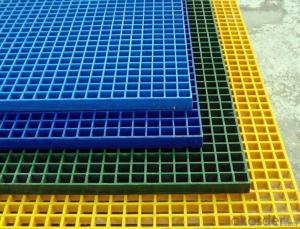

FRP Molded Grating is a structural panel which uses high-strength E-Glass roving as reinforcing material, thermosetting resin as matrix and then casted and formed in a special metal mold. It provides properties of light weight, high strength, corrosion resistance, fire resistance and anti-skid. FRP Molded Grating is widely used in oil industry, power engineering, water & waste water treatment, ocean survey as working floor, stair tread, trench cover, etc. and is an ideal loading frame for corrosion circumstances.

Feature

Corrosion Resistance

Fire Resistance

Light Weight & High Strength

Safety & Anti-slip

Electrical Insulating

Aging Resistance

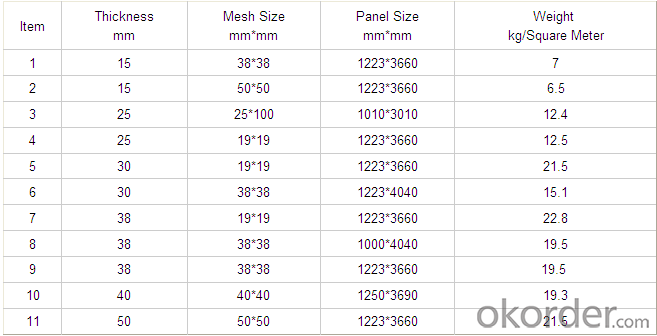

Specification

Advantage

coated with prevent aging layer

excellent insulating performance

no maintenance

high strength

long service life

easy installation

Application

Power plants, substation equipment enclosures, antimagnetic, anti-static,to prevent small animals into the equipment failure, as there is electricity facilities and without power interval intervals.

In high voltage electrical equipment for power line work, in order to prevent workers go wrong location, charged interval or near electrically charged equipment to dangerous distance.

Pool railings in sewage treatment industry

Corrosive chemical industry equipment around the fence

All kinds of building maintenance section

FAQ

1. How about the documents after shipment?

After shipment, we ll send all original documents to you by DHL, including Packing List.Commercial Invoice, B/L, and other certificates as required by clients.

2. How long is the delivery time?

Usually it takes 10-25days after receipt of the deposits or L/C, and it also depends on the quantity of your order.

3. How's the payment?

Telegraphic Transfer(T/T) or Letter of Credit(L/C)

4. Do You Arrange Shipment?

Yes, dear esteemed customers, for FOB or CIF price, we will arrange shipment for you. For EXW price, clients need to arrange shipment by themselves or their agents.

5. How is the package?

Usually, we arrange the standard out-package for exporting.

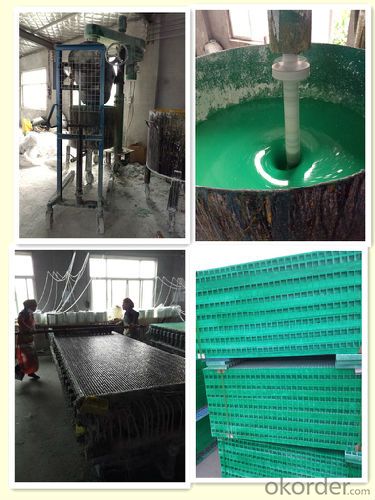

PROCESS

FACTORY

- Q:theres silk, cotton,????? please tell me i would like to kno some brand names to! :)

- Linen, polyester, velvet now talking about brand names for cloth you may not believe but the biggest luxury retail brands of europe america buy cloth from indian sri lanka bangladeshi companies you may have not even heard of thats a big reason they make profits in millions

- Q:What is the difference between building ventilation duct material, FRP pipe material and fiber reinforced magnesia pipe type MFR7 composite duct material?

- Glass steel duct material, high surface smoothness, beautiful appearance, small deformation, light weight; fiber reinforced magnesium duct type MFR7 composite wind pipe material is low cost, simple molding, moderate strength, complete flame retardant, good fire proofing.

- Q:The boat I bought had plywood layed over fiberglass i believe. After I removed the plywood off I noticed that the fiberglass decking has soft spots in it. What should I do I am sure that i will have to remove the floor but do I have to refiberglass or can I just put marine plywood down and just seal it really good? thanks for any help.

- are you using marine plywood ? Get to the square point of the boat and the bow pointed front of your boat . measure across the inside square area and write that down then next --measure (M) forward write that down (w) and then go forward about six inches advancement towards the pointy bow and '''Mw''' until you get to the front.keeping in mind that the thickness of the plywood is in relation to the curve of the sides of the boat . When you get all the way to the front of boat you are on the way ---- to keep M's straight tick mark with a magical marker to help you know what has been Mw -- now go to the cardboard pattern mark and cut the cardbd and try to make sense of all the measurements and then you fit the cardbd and if it works you are ready to cut the wood. If you have a small gap some where it will probably be covered up by the outdoor carpet that you use to make a sure-grip flooring surface . OK if you have more problems you can e-mail me and add me to yo contax list. WALTER CHAOS

- Q:The charge on the mirror‘s surface should be positive, I know that. But I don‘t know what this charge‘s effect on the glass would be. Would the glass shine in some way, or something?Thanks in advance.

- Refere to the chart on the link below for VERY POSITIVE AND VERY NEGITIVE As glass is near very positve and nylon(polyeter) is midway between neutral and very negative (so negative). SO static electricity will be produced between two. And you will observe sparking between two surfaces. CHART: * Human hands (usually too moist, though)-------------- Very positive * Rabbit Fur * Glass * Human hair * Nylon * Wool * Fur * Lead * Silk * Aluminum * Paper * Cotton * Steel-----------------------------------. Neutral * Wood * Amber * Hard rubber * Nickel, Copper * Brass, Silver * Gold, Platinum * Polyester * Styrene (Styrofoam) * Saran Wrap * Polyurethane * Polyethylene (like Scotch Tape) * Polypropylene * Vinyl (PVC) * Silicon * Teflon ---------------------------------Very negative

- Q:I‘ve bought Rit before but it made my blue hoodie purple. I want to try to dye my pink sweats from Victoria‘s Secret brand pink. and red and blue bright coloured cotton plaid shirt from aritzia. Will they turn out purple? How do I make them black? What brand would be a good fabric dye at a decent price?

- If you have polyester in your clothing, you're going to have a hard time dying it the correct color. Dyes like cotton more than synthetic materials. Do some research on correctly dying clothing that contains synthetic materials.

- Q:I use chamois a lot to blend my drawings. How can I wash/clean the fabric to keep its softness?

- Real chamois is specially treated leather; Rinse in plain water if needed; wash with a mild, neutral detergent (baby shampoo is great) and rinse multiple times in plain water if you're working with real chamois. If the leather is stiff after drying, roll it up with a damp cloth for a few minutes. If you're working with chamois cloth, most are nylon or polyester with a brushed or pile finish. Toss it in the washer and dryer.

- Q:is it only polyester and cotton (fleece)

- There are literally dozens of materials that clothes can be made from the most common being silk, cotton, wool and polyester. Fleece (like a fleece jacket) is usually a synthetic fabric and isn't cotton. I personally like clothes made out of natural fabrics like wool, silk and cotton.

- Q:How to do waterproof coating on the roof of color steel plate?

- Metal roof gutter: gutter joint, water hole at the first local waterproof metal roofing system, and then to a greater range of waterproof coating a layer of paint, it is still in the wet laid polyester sewing cloth, and then from the above goal with good slurry fully infiltrated sewing polyester cloth, and the whole stem.

- Q:I have no idea how to decide what kind of fabrics to order my Chair Covers, Sashes, Table Cloths, Table Runners, Napkins, and anything else I may need for our wedding in. On a few sites I‘ve been looking at the choices are Polyester or Satin. How do I know which to order? Should I be picking something else? Should everything be the same fabric? How do you know what to to choose? Does anyone have a site they‘ve ordered from and been satisfied with or have ones they‘ve had bad experiences with? (I am in Canada if that makes any difference ;) )

- Hi! That's a normal thing when you are planning for a wedding, there are a lot of choices and it makes you confused. For me, when choosing for a decoration you need to based it on the theme. If the wedding is a red themed wedding then opt for fabrics that are red in color but with romantic designs. For you to have an idea, you can check the sample weddings of weddingstar and they a lot of wedding decors too. I think it's perfect for what you are looking for. :) Just an idea!

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

FRP Molded Grating /GRP Grating / FRP Grating

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords