FRP Grating, FRP Molded Grating, FRP Fiberglass Plastic Walkway Grating with Best Quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction

FRP Molded Grating is a structural panel which uses high-strength E-Glass roving as reinforcing material, thermosetting resin as matrix and then casted and formed in a special metal mold. It provides properties of light weight, high strength, corrosion resistance, fire resistance and anti-skid. FRP Molded Grating is widely used in oil industry, power engineering, water & waste water treatment, ocean survey as working floor, stair tread, trench cover, etc. and is an ideal loading frame for corrosion circumstances.

Feature

l Corrosion Resistance

l Fire Resistance

l Light Weight & High Strength

l Safety & Anti-slip

l Electrical Insulating

l Aging Resistance

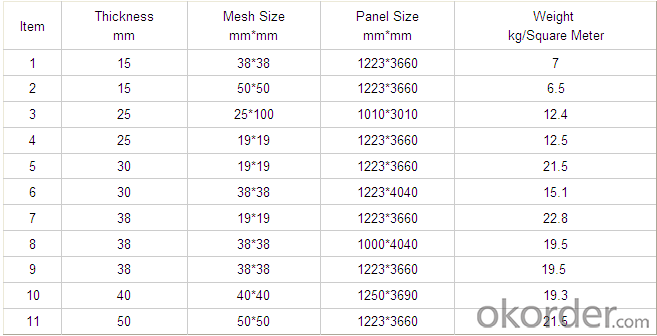

Specification

Advantage

1) coated with prevent aging layer

2) excellent insulating performance

3) no maintenance

4) high strength

5) long service life

6) easy installation

Application

l Power plants, substation equipment enclosures, antimagnetic, anti-static,to prevent small animals into the equipment failure, as there is electricity facilities and without power interval intervals.

l In high voltage electrical equipment for power line work, in order to prevent workers go wrong location, charged interval or near electrically charged equipment to dangerous distance.

l Pool railings in sewage treatment industry

l Corrosive chemical industry equipment around the fence

l All kinds of building maintenance section

FAQ

1. How about the documents after shipment?

After shipment, we ll send all original documents to you by DHL, including Packing List.Commercial Invoice, B/L, and other certificates as required by clients.

2. How long is the delivery time?

Usually it takes 10-25days after receipt of the deposits or L/C, and it also depends on the quantity of your order.

3. How's the payment?

Telegraphic Transfer(T/T) or Letter of Credit(L/C)

4. Do You Arrange Shipment?

Yes, dear esteemed customers, for FOB or CIF price, we will arrange shipment for you. For EXW price, clients need to arrange shipment by themselves or their agents.

5. How is the package?

Usually, we arrange the standard out-package for exporting.

PROCESS

FACTORY

- Q:Are FRP pultrusion profiles resistant to termites or other pests?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles are inherently resistant to termites and other pests. Unlike traditional wood or metal materials, FRP profiles do not provide a food source for termites or any other pests. FRP is composed of a combination of reinforced fibers and a polymer matrix, typically made of fiberglass and resin. These materials are not appealing to pests and do not provide any nutritional value, making FRP profiles highly resistant to termite damage or infestation. This resistance to pests is one of the many advantages of using FRP pultrusion profiles in various applications, especially in outdoor or humid environments where termites are commonly found.

- Q:Are FRP pultrusion profiles resistant to termites?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles are generally resistant to termites. Termites primarily feed on cellulose-based materials, such as wood, and since FRP pultrusion profiles are made of a combination of resin and glass fibers, they do not contain cellulose and therefore are not attractive to termites. This makes FRP pultrusion profiles a great alternative to traditional wooden profiles when it comes to applications where termite resistance is required, such as in building construction and outdoor structures. Additionally, FRP profiles are also resistant to rot, corrosion, and other environmental factors, making them a durable and long-lasting material choice.

- Q:Can FRP pultrusion profiles be used in the transportation and logistics industry?

- Yes, FRP pultrusion profiles can be used in the transportation and logistics industry. These profiles offer a lightweight and high-strength alternative to traditional materials like steel or aluminum. They are resistant to corrosion, have excellent dimensional stability, and can be customized to meet specific design requirements. FRP pultrusion profiles are commonly used in applications such as truck bodies, trailers, shipping containers, and infrastructure for transportation and logistics purposes.

- Q:Are FRP pultrusion profiles resistant to electromagnetic interference?

- FRP pultrusion profiles are known for their resistance to electromagnetic interference (EMI). By using fiberglass reinforced plastic (FRP) in pultrusion profiles, they offer exceptional electrical insulation properties that effectively minimize the impact of electromagnetic interference. Unlike conductive metals, FRP materials possess high dielectric strength and low electrical conductivity. As a result, FRP pultrusion profiles are less vulnerable to EMI and can serve as barriers against electromagnetic waves. Moreover, if necessary, additional layers or coatings can be applied to enhance the EMI shielding effectiveness of FRP materials. In conclusion, for applications where resistance to electromagnetic interference is crucial, FRP pultrusion profiles are a dependable choice.

- Q:Can FRP pultrusion profiles be used in agricultural structures?

- Agricultural structures can indeed utilize FRP pultrusion profiles. FRP pultrusion profiles, also known as Fiber Reinforced Polymer profiles, possess numerous advantages that render them suitable for agricultural purposes. To begin with, the corrosion resistance of FRP profiles is of utmost importance in the agricultural industry, given the exposure of structures to harsh environments and chemicals like fertilizers and pesticides. Unlike conventional materials such as steel or wood, FRP does not rust or decay, ensuring enduring performance in agricultural structures. Furthermore, FRP profiles are lightweight yet durable, facilitating easy handling and installation in agricultural applications. Their high strength-to-weight ratios enable efficient construction, thereby reducing the necessity for heavy machinery during the installation process. Moreover, FRP profiles exhibit exceptional mechanical properties, including high stiffness and impact resistance, which prove advantageous for agricultural structures subjected to heavy loads, vibrations, or machinery impact. In addition, FRP pultrusion profiles can be designed to resist UV radiation, thereby preventing degradation from prolonged exposure to sunlight. This quality makes them suitable for outdoor agricultural structures consistently exposed to the elements. Lastly, FRP profiles are non-conductive, a critical advantage in agricultural environments where electrical safety is paramount. This characteristic eliminates the risk of electrical hazards associated with conductive materials like steel. In summary, FRP pultrusion profiles offer a reliable and efficient solution for a variety of agricultural structures, such as greenhouse frames, livestock enclosures, irrigation systems, and storage facilities. Their corrosion resistance, lightweight nature, high strength, UV resistance, and non-conductivity make them an ideal choice for agricultural applications.

- Q:Are FRP pultrusion profiles suitable for the manufacturing of antenna masts?

- Yes, FRP pultrusion profiles are suitable for the manufacturing of antenna masts. FRP pultrusion profiles offer several advantages such as high strength-to-weight ratio, corrosion resistance, and excellent electrical insulation properties. These characteristics make them ideal for antenna mast construction, as they can withstand various environmental conditions and provide reliable support for antennas.

- Q:How do FRP pultrusion profiles perform in high humidity environments?

- FRP pultrusion profiles excel in environments with high humidity due to their exceptional performance. The inherent qualities of FRP, such as its resistance to corrosion and moisture, make it an ideal material for applications exposed to moisture or high levels of humidity. One major advantage of FRP pultrusion profiles is their non-porous nature, which means they do not absorb moisture. This characteristic prevents the profiles from swelling, warping, or deteriorating when exposed to high humidity. Unlike traditional materials like wood or steel, FRP does not degrade or lose its structural integrity in humid conditions. Furthermore, FRP pultrusion profiles have a high resistance to chemicals, including the corrosive effects of moisture and humidity. This corrosion resistance is a result of the composite nature of FRP, which combines a matrix material (typically a resin) with reinforcing fibers, such as glass or carbon fibers. This combination provides excellent resistance to water and moisture-induced corrosion, ensuring the long-term performance of FRP profiles in high humidity environments. Moreover, FRP pultrusion profiles exhibit excellent dimensional stability, even under extreme variations in temperature and humidity. They do not significantly expand or contract, maintaining their shape and structural integrity in diverse environmental conditions. This stability makes FRP profiles suitable for applications in coastal regions, wastewater treatment plants, chemical processing plants, and other environments with high humidity levels. In conclusion, FRP pultrusion profiles are specifically designed to withstand harsh conditions, including high humidity environments. Their non-porous nature, corrosion resistance, and dimensional stability make them a dependable and durable choice for various applications in humid climates.

- Q:What is the impact resistance of FRP pultrusion profiles?

- FRP pultrusion profiles exhibit a remarkably high level of impact resistance. These profiles are produced by pulling reinforcing fibers, such as fiberglass, through a resin bath and then into a heated die, where the resin solidifies and cures. This manufacturing technique generates a durable and robust composite material with exceptional mechanical properties, including impact resistance. The impact resistance of FRP pultrusion profiles may differ depending on the specific formulation, design, and orientation of the reinforcing fibers employed. Nevertheless, in general, FRP pultrusion profiles have been proven to possess superior impact resistance when compared to traditional materials like steel or aluminum. The combination of reinforcing fibers and the resin matrix in FRP pultrusion profiles provides enhanced strength and toughness, enabling the profiles to withstand substantial impact loads without cracking, breaking, or deforming. Consequently, these profiles are highly suitable for a diverse range of applications where impact resistance is of utmost importance, such as in construction, transportation, and sporting goods. Furthermore, the impact resistance of FRP pultrusion profiles can be customized by adjusting factors such as fiber content, fiber orientation, and resin type during the manufacturing process. This allows for tailored profiles that meet specific application requirements. In summary, FRP pultrusion profiles deliver outstanding impact resistance due to the integration of reinforcing fibers and resin matrix. Their exceptional strength, toughness, and ability to endure impact loads make them a dependable choice across various industries and applications.

- Q:What is the torsional strength of FRP pultrusion profiles?

- The torsional strength of FRP pultrusion profiles can vary depending on the specific composition and design of the profile. However, in general, FRP pultrusion profiles tend to have high torsional strength due to the inherent properties of the fiber-reinforced polymers used in their construction. These materials are known for their excellent resistance to torsional forces, which makes FRP pultrusion profiles suitable for applications requiring high torsional strength.

- Q:Can FRP pultrusion profiles be used in the water and wastewater treatment industry?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in the water and wastewater treatment industry. FRP pultrusion profiles are highly durable, corrosion-resistant, and have excellent mechanical properties, making them suitable for various applications in the water and wastewater treatment industry. One of the main advantages of FRP pultrusion profiles is their resistance to corrosion. Water and wastewater treatment facilities often deal with aggressive chemicals, high humidity, and corrosive environments. Traditional materials like steel or wood may deteriorate and require frequent maintenance or replacement. However, FRP pultrusion profiles are specifically designed to withstand harsh conditions without corrosion, ensuring long-term performance and reducing maintenance costs. Additionally, FRP pultrusion profiles offer excellent strength-to-weight ratio, making them ideal for structural applications in water and wastewater treatment facilities. They can be used as walkways, handrails, grating, ladders, and other structural components. The lightweight nature of FRP profiles allows for easy installation and minimizes the load on the supporting structures. Furthermore, FRP pultrusion profiles are non-conductive, providing an added safety benefit in water and wastewater treatment facilities. This property is particularly important when dealing with electrical equipment or applications near water sources, reducing the risk of electrical hazards. Moreover, FRP pultrusion profiles can be customized to meet specific design requirements, including different shapes, sizes, and colors. This flexibility allows for greater design freedom, ensuring that the profiles can be tailored to fit the specific needs of water and wastewater treatment projects. Overall, the use of FRP pultrusion profiles in the water and wastewater treatment industry offers numerous advantages, including corrosion resistance, high strength, lightweight, non-conductivity, and design flexibility. These qualities make FRP profiles a reliable and cost-effective choice for various applications in this industry.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

FRP Grating, FRP Molded Grating, FRP Fiberglass Plastic Walkway Grating with Best Quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords