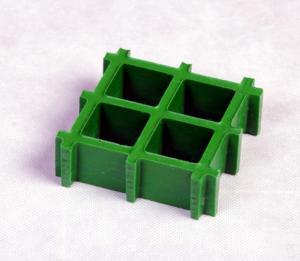

FRP Grating for Walkway with all kinds of colors

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction

FRP Molded Grating is a structural panel which uses high-strength E-Glass roving as reinforcing material, thermosetting resin as matrix and then casted and formed in a special metal mold. It provides properties of light weight, high strength, corrosion resistance, fire resistance and anti-skid. FRP Molded Grating is widely used in oil industry, power engineering, water & waste water treatment, ocean survey as working floor, stair tread, trench cover, etc. and is an ideal loading frame for corrosion circumstances.

Feature

Corrosion Resistance

Fire Resistance

Light Weight & High Strength

Safety & Anti-slip

Electrical Insulating

Aging Resistance

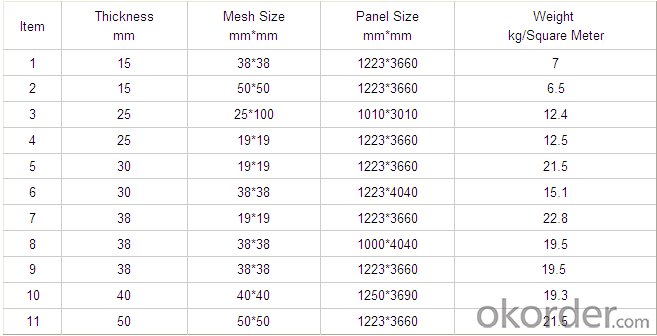

Specification

Advantage

coated with prevent aging layer

excellent insulating performance

no maintenance

high strength

long service life

easy installation

Application

Power plants, substation equipment enclosures, antimagnetic, anti-static,to prevent small animals into the equipment failure, as there is electricity facilities and without power interval intervals.

In high voltage electrical equipment for power line work, in order to prevent workers go wrong location, charged interval or near electrically charged equipment to dangerous distance.

Pool railings in sewage treatment industry

Corrosive chemical industry equipment around the fence

All kinds of building maintenance section

FAQ

1. How about the documents after shipment?

After shipment, we ll send all original documents to you by DHL, including Packing List.Commercial Invoice, B/L, and other certificates as required by clients.

2. How long is the delivery time?

Usually it takes 10-25days after receipt of the deposits or L/C, and it also depends on the quantity of your order.

3. How's the payment?

Telegraphic Transfer(T/T) or Letter of Credit(L/C)

4. Do You Arrange Shipment?

Yes, dear esteemed customers, for FOB or CIF price, we will arrange shipment for you. For EXW price, clients need to arrange shipment by themselves or their agents.

5. How is the package?

Usually, we arrange the standard out-package for exporting.

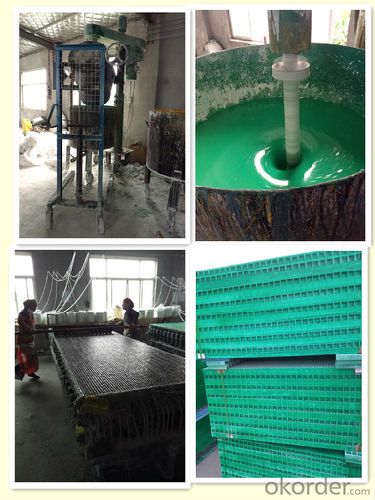

FACTORY

- Q:How do FRP pultrusion profiles handle compression loads?

- FRP pultrusion profiles handle compression loads by utilizing their high strength-to-weight ratio and inherent stiffness. The resin matrix and reinforcing fibers in the pultruded composite material work together to distribute and transmit the compression force, ensuring that the profiles are able to withstand and bear the applied load. The specific design of the profiles, including the orientation and arrangement of the fibers, further enhances their ability to resist compression and maintain structural integrity.

- Q:Can FRP pultrusion profiles be used in architectural or decorative applications?

- Certainly, architectural or decorative applications can definitely make use of FRP pultrusion profiles. FRP, an acronym for Fiber Reinforced Polymer, is a composite material that combines sturdy fibers like glass or carbon with a polymer resin matrix. This combination results in a material that is lightweight, durable, and resistant to corrosion, making it ideal for a variety of purposes, including architecture and decoration. The versatility of FRP pultrusion profiles lies in their ability to be manufactured in various shapes and sizes, making them highly adaptable for architectural and decorative uses. These profiles can be utilized to construct visually appealing structures such as columns, beams, and facades, all of which enhance the aesthetic appeal of buildings. Furthermore, FRP pultrusion profiles can be fabricated to imitate the appearance of other materials, such as wood or metal, enabling the creation of decorative elements that seamlessly blend into the overall design. Moreover, FRP pultrusion profiles offer several advantages over traditional materials commonly employed in architecture and decoration. They are lightweight, making them easier to handle and install, reducing labor costs. Additionally, they exhibit high resistance to corrosion, weathering, and UV radiation, ensuring long-lasting performance in outdoor applications. Furthermore, FRP profiles can be customized to meet specific design requirements, including color, texture, and surface finish, offering endless possibilities for creative expression. In summary, FRP pultrusion profiles are a viable choice for architectural and decorative applications. Their lightweight, durable, and customizable nature makes them suitable for a wide range of design needs, while their corrosion resistance guarantees longevity and low maintenance. Whether it is for structural support or decorative embellishments, FRP pultrusion profiles are an excellent option for enhancing the aesthetics and functionality of architectural and decorative projects.

- Q:Are FRP pultrusion profiles resistant to high winds or hurricanes?

- FRP pultrusion profiles offer exceptional resistance against high winds and hurricanes. Combining the robustness of fiberglass with the longevity of polymers, FRP is a lightweight yet remarkably sturdy material that can endure severe weather conditions. Extensive testing has proven that FRP pultrusion profiles exhibit outstanding wind resistance properties. They possess a remarkable stiffness-to-weight ratio, enabling them to withstand the powerful forces generated by high winds without deformation or breakage. Additionally, the inherent flexibility of FRP permits it to absorb and distribute wind forces, minimizing the risk of damage. In the face of hurricanes, FRP pultrusion profiles have demonstrated their capability to withstand the intense winds and airborne debris associated with such extreme weather events. They have been successfully employed in various applications, including building facades, bridges, and utility poles, in areas prone to hurricanes. Moreover, FRP pultrusion profiles possess corrosion resistance, providing an extra advantage in withstanding high winds and hurricanes. Unlike traditional materials like steel or wood, FRP profiles do not rust or decay when exposed to moisture, making them even more suitable for these demanding weather conditions. Overall, with their exceptional strength, durability, flexibility, and corrosion resistance, FRP pultrusion profiles are an excellent choice for applications requiring resistance against high winds or hurricanes.

- Q:Can FRP pultrusion profiles be used in transportation infrastructure, such as bridges or platforms?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in transportation infrastructure, including bridges and platforms. FRP profiles are lightweight, corrosion-resistant, and have high strength-to-weight ratio, making them suitable for these applications. They offer durability, long service life, and can be designed to meet specific load requirements. Additionally, FRP pultrusion profiles can be easily manufactured in various shapes and sizes, providing flexibility in design and construction.

- Q:Can FRP pultrusion profiles be used in the construction of water slides?

- Water slides can indeed utilize FRP pultrusion profiles. FRP, which stands for Fiber Reinforced Polymer, is a composite material that offers numerous advantages in the construction of water slides. To begin with, FRP pultrusion profiles possess a remarkable combination of lightweight construction and remarkable strength, making them an ideal choice for creating the structural components of water slides. These profiles boast impressive strength-to-weight ratios, meaning they can withstand the dynamic loads and forces experienced in water slide applications without adding excessive weight to the overall structure. Moreover, FRP pultrusion profiles exhibit exceptional resistance to corrosion, which is of utmost importance in water slide construction. Given that water slides are constantly exposed to water, chemicals, and harsh weather conditions, traditional materials like steel tend to corrode and deteriorate over time. In contrast, FRP profiles are inherently corrosion-resistant, guaranteeing the longevity and durability of the water slide. Furthermore, FRP pultrusion profiles offer an abundance of design flexibility. They can be tailored to various shapes and sizes, enabling the creation of unique and thrilling water slide designs. These profiles are also easily moldable, allowing for the incorporation of various features such as slides, curves, and drops to enhance the overall water slide experience. Lastly, FRP pultrusion profiles possess exceptional thermal insulation properties. This proves advantageous for water slides as it helps maintain the temperature of the water, preventing excessive heat loss or gain. Such a feature enhances the comfort and enjoyment of users while simultaneously reducing energy consumption for heating or cooling the water. In summary, FRP pultrusion profiles are perfectly suited for water slide construction due to their lightweight nature, impressive strength, corrosion resistance, design flexibility, and thermal insulation properties.

- Q:Are FRP pultrusion profiles resistant to hydrochloric acid?

- Yes, FRP pultrusion profiles are generally resistant to hydrochloric acid due to the corrosion-resistant properties of the fiberglass reinforcement and the resin matrix used in their construction. However, the specific resistance may vary depending on the composition and concentration of the acid, and it is recommended to consult the manufacturer's specifications for detailed information regarding chemical resistance.

- Q:Can FRP pultrusion profiles be used in the production of electrical cabinets?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can definitely be used in the production of electrical cabinets. FRP pultrusion profiles have excellent electrical insulating properties, making them a suitable choice for applications involving the production of electrical cabinets. These profiles are non-conductive and can provide insulation and protection against electrical currents, ensuring the safety of the electrical components housed within the cabinet. Additionally, FRP pultrusion profiles offer high strength-to-weight ratio, corrosion resistance, and durability, making them a reliable choice for long-lasting electrical cabinets in various environments.

- Q:Can FRP pultrusion profiles be used in walkway systems?

- Yes, FRP pultrusion profiles can be used in walkway systems. FRP pultrusion profiles are lightweight, strong, and resistant to corrosion, making them suitable for use in various applications, including walkways. They offer durability, low maintenance, and can withstand heavy loads, making them a reliable choice for walkway systems.

- Q:Are FRP pultrusion profiles resistant to electrical arcing?

- FRP pultrusion profiles are generally resistant to electrical arcing. This is because they are made from non-conductive materials like fiberglass reinforced plastic. These profiles do not conduct electricity, which makes them ideal for applications where electrical arcing or conductivity is a concern. However, it is important to note that the specific resistance to electrical arcing may vary depending on the specific composition and design of the FRP pultrusion profiles. It is recommended to consult with the manufacturer or supplier of the profiles to ensure they meet the required electrical resistance standards for a particular application.

- Q:Can FRP pultrusion profiles be used in agricultural structures?

- Yes, FRP pultrusion profiles can certainly be used in agricultural structures. They offer several advantages such as high strength-to-weight ratio, corrosion resistance, and durability, making them suitable for various applications in the agricultural industry. These profiles can be used in structures like greenhouse frames, livestock enclosures, support beams, fencing, and other agricultural infrastructure.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

FRP Grating for Walkway with all kinds of colors

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords