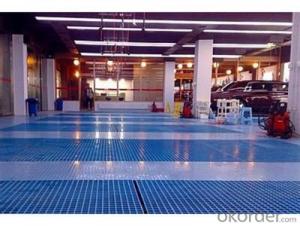

FRP Grating for Carwash Floor New Style

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification of FRP Grating for Carwash Floor:

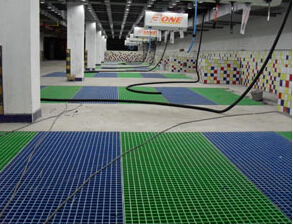

FRP grating for carwash floor is one kind of glass fiber reinforced plastic (FRP) by using glass fiber for reinforcement, unsaturated polyester resin as matrix, through special processing and become a kind of plate material, with lots of blank space in hebei leading production of glass FRP grasting can be used as a structural material, used for the floor of the corrosion environment, trench cover, platform, ship deck, stair, catwalks, etc.

FRP grating by glass fiber braiding, resin pouring the whole moulding, production with many rules of distribution of rectangle, square space of glass FRP grating plate, with two-way same-sex mechanics characteristics. FRP grating can be widely used in petroleum, chemical industry electronic, electric power, paper, printing and dyeing, electroplating, sewage treatment and other industries, Marine exploration work platforms, equipment platforms, drilling platform, walkway, etc., FRP grating is the ideal product in corrosive environment, at the same time can also be applied to civil construction facilities.

Due to our FRP grating can bear the presence of corrosive liquid, gas, metal corrosion rapidly in these areas, although the anti-corrosion layer and other measures, but for the components of the corrosion is still surprisingly, not only cause bad production environment, and affect production safety, FRP grating sometimes have to stop production maintenance, in the use of FRP grating as structural materials in these regions can have very good effect, it has a long service life, low cost, safe and reliable, no maintenance, and beautiful and easy, and a series of advantages. Of such products in the United States has used more than 30 years, the use, production sales of FRP grating has been standardization, seriation, commercialization, dosage is considerable. , the Middle East oil field in the gulf of reconstruction, the expert argumentation, and think that the use of FRP grating is the most economic and reasonable material, and therefore are a lot of use. In Asia, Singapore and other regions are also using FRP grating.

FRP grating performance characteristics are as follows:

Corrosion resistant

FRP grating has very excellent acid-proof, alkali resistance, resistance to organic solvents and salt, and many other gas and liquid medium corrosion performance, has the incomparable superiority in the field of anti-corrosion. According to the practical application requirements, can choose to use economically o-type, between benzene, vinyl resin base material.

Light weight, high strength, and is convenient for cutting, installation

Because it is by the resin and glass fiber composite, FRP grating density is not more than 2 kg each smaller CDM, is only a quarter of the steel, aluminum two-thirds. 10 times the strength of rigid polyvinyl chloride (PVC), absolute strength more than aluminum and the level of the ordinary steel. Its light weight, can greatly reduce the foundation support, thus reducing the material cost of the project. Its cutting easy installation, without hot and large-scale lifting equipment, only a small amount of manual and electric tools, makes the installation costs are greatly reduced.

Resistance to aging

In theory, the FRP grating service life of over 50 years.

Flame retardant

Ordinary FRP grating flame propagation rate (ASTM E - 84) is not more than 25; Advanced flame retardant vinyl grille the flame propagation rate of no more than 10. Oxygen index is not less than 28 (GB 8924).

Security of FRP Grating

FRP Grating has excellent electrical insulation, 10 kv voltage without breakdown; Without electricity, magnetic available in sensitive to magnetic devices; Glass fiber reinforced plastic FRP grating special structure also has the characteristics such as non-slip, anti-fatigue.

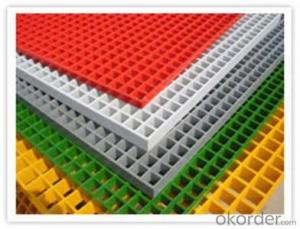

FRP Grating Color

Colors can be arbitrary choice. Can according to customer request custom color, improve the environment in the workplace. General FRP gratings are: yellow, black, grey, green, blue, red and transparent or translucent, etc. In use process can use a single color, also can match.

FRP Grating Can design a strong

Size flexible, convenient and cutting, size stability.

- Q:Are FRP pultrusion profiles resistant to UV degradation?

- FRP pultrusion profiles typically possess strong resistance against UV degradation. These profiles, constructed from a blend of resin and glass fibers, are designed to endure extended sun exposure. The resin utilized in their production is customarily engineered to provide UV radiation resistance. This resistance effectively safeguards the FRP pultrusion profiles from the detrimental effects of prolonged sunlight exposure. Extensive testing has confirmed the exceptional UV resistance of FRP pultrusion profiles. Consequently, they are frequently employed in outdoor settings, such as construction, infrastructure, and marine industries, where they are subject to sunlight exposure. The UV resistance guarantees that these profiles maintain their structural integrity, color, and aesthetic appeal over an extended period. However, it is crucial to acknowledge that the level of UV resistance may differ based on the specific resin formulation used during manufacturing. Various manufacturers employ different resins containing varying levels of UV stabilizers. It is advisable to consult the manufacturer or supplier to ensure that the chosen FRP pultrusion profiles are specifically designed to withstand the UV conditions of the intended application. Regular maintenance and periodic inspection of the FRP pultrusion profiles are also vital to ensure their long-term UV resistance. This may involve cleaning, applying protective coatings, or utilizing UV-blocking additives if necessary. By taking these precautions, the UV resistance of FRP pultrusion profiles can be further enhanced, securing their durability and longevity in outdoor environments.

- Q:Are FRP pultrusion profiles resistant to wear or abrasion?

- FRP pultrusion profiles exhibit exceptional durability against wear and abrasion due to the integration of reinforcing fibers, predominantly glass or carbon, and a plastic resin matrix. This combination results in a highly robust material that can endure rigorous utilization. Moreover, the pultrusion process guarantees a uniform composition, with fibers uniformly dispersed throughout the profile, thereby augmenting its resistance to wear and abrasion. Furthermore, FRP pultrusion profiles can be customized with specific additives or surface treatments to further heighten their ability to withstand wear and abrasion, rendering them suitable for diverse applications across industries such as construction, transportation, and marine.

- Q:What are the typical applications of FRP pultrusion profiles?

- FRP (Fiber Reinforced Polymer) pultrusion profiles have a wide range of applications due to their unique properties. Some of the typical applications of FRP pultrusion profiles include: 1. Construction and Infrastructure: FRP profiles are used for various structural elements in buildings, bridges, and other infrastructure projects. They are commonly used for beams, columns, decks, and reinforcement due to their high strength-to-weight ratio, corrosion resistance, and durability. 2. Industrial and Chemical Processing: FRP profiles are extensively used in the industrial sector for applications such as platforms, walkways, ladders, and handrails. They offer excellent resistance to chemicals, heat, and corrosion, making them suitable for harsh environments. 3. Electrical and Telecommunication: FRP profiles are utilized for cable trays, ladder racks, and support structures in electrical and telecommunication systems. They provide electrical insulation and are non-conductive, ensuring safety and reliability in these applications. 4. Transportation: FRP profiles find applications in the transportation industry, particularly in the manufacturing of lightweight components for vehicles, including buses, trains, and trucks. They help reduce weight, improve fuel efficiency, and enhance the overall performance of these vehicles. 5. Marine and Offshore: FRP pultrusion profiles are well-suited for marine and offshore applications due to their resistance to saltwater, UV radiation, and harsh environmental conditions. They are used for boat hulls, piers, dock fenders, and other offshore structures. 6. Recreation and Sports: FRP profiles are employed in the production of various recreational equipment such as ladders, slides, playground equipment, and sports accessories. Their high strength, durability, and resistance to weather elements make them ideal for these applications. 7. Water Treatment and Wastewater Management: FRP profiles are widely used in water treatment plants, sewage systems, and wastewater management facilities. They are used for grating, handrails, ladders, and other structural components due to their resistance to chemicals and corrosion. Overall, the versatility, strength, corrosion resistance, and lightweight nature of FRP pultrusion profiles make them suitable for a diverse range of applications in different industries.

- Q:Can FRP pultrusion profiles be used in water treatment plants?

- Yes, FRP pultrusion profiles can be used in water treatment plants. FRP (Fiber-Reinforced Polymer) is a corrosion-resistant material that is well-suited for water treatment applications. It is lightweight, durable, and has excellent chemical resistance properties, making it ideal for use in environments with exposure to water and various chemicals. Additionally, FRP pultrusion profiles offer design flexibility and can be customized to meet specific project requirements.

- Q:Can FRP pultrusion profiles be used in telecommunications towers?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in telecommunications towers. FRP materials offer several advantages for such applications, including high strength-to-weight ratio, corrosion resistance, and electrical non-conductivity. These properties make FRP pultrusion profiles suitable for use in telecommunications towers, providing structural support while offering durability and longevity.

- Q:Are FRP pultrusion profiles resistant to rotting or decaying?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles are highly resistant to rotting or decaying. This is because FRP is composed of a combination of fiber reinforcement, such as fiberglass, and a polymer resin matrix. Unlike traditional materials like wood, which are susceptible to rot and decay when exposed to moisture and environmental elements, FRP pultrusion profiles are non-porous and do not absorb water. Additionally, the polymer resin used in FRP is highly resistant to chemical corrosion, making it unaffected by rot-causing agents such as fungi or bacteria. As a result, FRP pultrusion profiles have a significantly longer lifespan and require minimal maintenance compared to traditional materials, making them an excellent choice for applications where resistance to rotting or decaying is essential.

- Q:How do FRP pultrusion profiles perform in high-vibration applications?

- High-vibration applications are where FRP (Fiber Reinforced Polymer) pultrusion profiles truly excel. The exceptional properties of FRP materials make them an ideal choice for these situations. To begin with, FRP pultrusion profiles are renowned for their impressive strength-to-weight ratio. Unlike traditional materials like steel or aluminum, FRP profiles are significantly lighter while still possessing remarkable strength and rigidity. This lightweight quality reduces the overall mass of the structure, resulting in lower vibration amplitudes. Furthermore, FRP materials boast outstanding damping characteristics. Damping refers to a material's ability to dissipate energy and decrease vibration amplitudes. In comparison to other materials, FRP pultrusion profiles have a higher damping coefficient, meaning they can more effectively absorb and dissipate vibrations. This minimizes the transmission of vibrations throughout the structure, reducing the risk of resonance and fatigue failure. In addition, FRP pultrusion profiles demonstrate exceptional resistance to fatigue and corrosion. Vibrations can cause cyclic loading, which can lead to fatigue failure over time. However, the inherent properties of FRP materials, including their excellent tensile strength and resistance to environmental factors, make them highly resilient to fatigue and corrosion. This guarantees the longevity and durability of the profiles, even in high-vibration environments. Moreover, FRP pultrusion profiles offer immense design flexibility, allowing for customized shapes and sizes that can be tailored to specific applications. This flexibility allows engineers to optimize the profiles' performance in high-vibration scenarios by adjusting the geometry and composition to enhance their dynamic characteristics. In summary, FRP pultrusion profiles are exceptionally suited for high-vibration applications due to their lightweight nature, excellent damping characteristics, resistance to fatigue and corrosion, and design flexibility. These profiles provide a reliable and durable solution that can effectively withstand the challenges posed by vibrations, ensuring safe and efficient operation in such environments.

- Q:Are FRP pultrusion profiles resistant to moisture or humidity?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles are highly resistant to moisture and humidity. The pultrusion process involves impregnating continuous fibers with a polymer resin, resulting in a strong and durable composite material. This composite is inherently moisture-resistant and does not absorb water like traditional materials such as wood or metal. Additionally, FRP pultrusion profiles have a low coefficient of thermal expansion, meaning they are less likely to expand or contract under varying levels of humidity. This resistance to moisture and humidity makes FRP pultrusion profiles suitable for a wide range of applications, including outdoor structures, marine environments, and other moisture-prone areas.

- Q:Can FRP pultrusion profiles be used for structural applications?

- Yes, FRP pultrusion profiles can be used for structural applications. They are commonly utilized in various industries such as construction, automotive, aerospace, and marine. FRP pultrusion profiles offer high strength-to-weight ratio, excellent corrosion resistance, and durability, making them suitable for structural components like beams, columns, and trusses. Additionally, they can be designed to meet specific load requirements and offer design flexibility.

- Q:What is the lifespan of FRP pultrusion profiles?

- The lifespan of FRP pultrusion profiles can vary depending on various factors such as the quality of the material, environmental conditions, and the application they are used in. However, in general, FRP pultrusion profiles have a long lifespan and can last for several decades with proper maintenance and care.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

FRP Grating for Carwash Floor New Style

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords