FRP Grating/ Fiberglass Solid Grille/Water Resistance Steel Grating with Various of Colors

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction

FRP Molded Grating is a structural panel which uses high-strength E-Glass roving as reinforcing material, thermosetting resin as matrix and then casted and formed in a special metal mold. It provides properties of light weight, high strength, corrosion resistance, fire resistance and anti-skid. FRP Molded Grating is widely used in oil industry, power engineering, water & waste water treatment, ocean survey as working floor, stair tread, trench cover, etc. and is an ideal loading frame for corrosion circumstances.

Feature

Corrosion Resistance

Fire Resistance

Light Weight & High Strength

Safety & Anti-slip

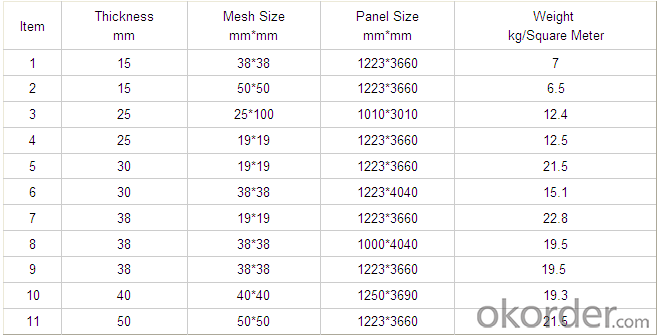

Specification

Advantage

coated with prevent aging layer

excellent insulating performance

no maintenance

high strength

Application

Power plants, substation equipment enclosures, antimagnetic, anti-static,to prevent small animals into the equipment failure, as there is electricity facilities and without power interval intervals.

In high voltage electrical equipment for power line work, in order to prevent workers go wrong location, charged interval or near electrically charged equipment to dangerous distance.

Pool railings in sewage treatment industry

Corrosive chemical industry equipment around the fence

FAQ

1. How about the documents after shipment?

After shipment, we ll send all original documents to you by DHL, including Packing List.Commercial Invoice, B/L, and other certificates as required by clients.

2. Do You Arrange Shipment?

Yes, dear esteemed customers, for FOB or CIF price, we will arrange shipment for you. For EXW price, clients need to arrange shipment by themselves or their agents.

3. How is the package?

Usually, we arrange the standard out-package for exporting.

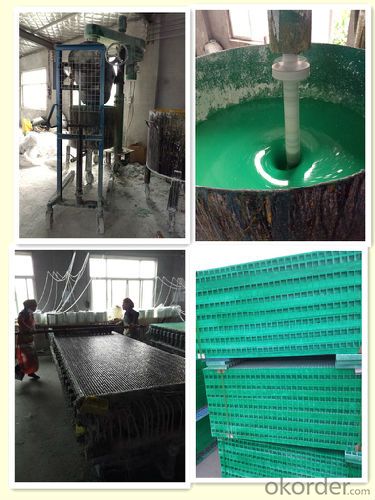

PROCESS

FACTORY

- Q:Are FRP pultrusion profiles resistant to electrical surges or lightning strikes?

- FRP pultrusion profiles are inherently non-conductive materials, which means they do not conduct electricity. Therefore, they can provide some level of resistance to electrical surges or lightning strikes. However, it is important to note that the level of resistance may vary depending on the specific composition and thickness of the FRP profiles. In high-risk areas prone to lightning strikes, additional measures may be necessary to ensure proper protection against electrical surges.

- Q:Can FRP pultrusion profiles be used in the telecommunications and data communication industry?

- Yes, FRP (Fiber Reinforced Plastic) pultrusion profiles can be used in the telecommunications and data communication industry. FRP pultruded profiles have several advantages that make them suitable for use in this industry. Firstly, FRP pultrusion profiles offer excellent electrical insulation properties, making them ideal for applications in the telecommunications and data communication industry where electrical conductivity needs to be minimized. FRP profiles do not conduct electricity, ensuring that there are no interference or grounding issues that could disrupt the transmission of data. Secondly, FRP pultrusion profiles are lightweight yet strong, providing a high strength-to-weight ratio. This makes them suitable for use in the construction of communication towers, antenna supports, and satellite dish mountings, where the profiles need to withstand wind loads and other environmental stresses. Additionally, FRP profiles have excellent corrosion resistance, which is crucial in the telecommunications and data communication industry where equipment is often exposed to harsh outdoor environments. Unlike traditional materials such as steel or aluminum, FRP profiles do not rust or corrode, ensuring the longevity and reliability of the infrastructure. Furthermore, FRP profiles can be easily customized and manufactured in various shapes and sizes to meet the specific requirements of telecommunications and data communication applications. This flexibility allows for the design and construction of complex structures that can accommodate different equipment and technologies. Overall, FRP pultrusion profiles offer a range of benefits that make them well-suited for use in the telecommunications and data communication industry. Their electrical insulation properties, lightweight yet strong nature, corrosion resistance, and flexibility in design make them a reliable choice for supporting infrastructure in this sector.

- Q:Can FRP pultrusion profiles be used in the construction of railway platforms?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in the construction of railway platforms. FRP profiles are lightweight, durable, and corrosion-resistant, making them suitable for various structural applications. They offer high strength-to-weight ratio, reducing the load on the platform structure while maintaining structural integrity. Additionally, FRP profiles can be customized to meet specific design requirements, providing flexibility in creating efficient and long-lasting railway platforms.

- Q:Can FRP pultrusion profiles be used in automotive applications?

- FRP pultrusion profiles can indeed be utilized in automotive applications, presenting a myriad of advantages that render them appropriate for such use. Firstly, these profiles possess the dual attributes of being lightweight and strong, which holds immense significance within the automotive industry. As weight reduction stands as a top priority for enhancing fuel efficiency and performance, the commendable strength-to-weight ratio of FRP profiles enables the creation of lighter vehicles that consume less fuel. Secondly, FRP pultrusion profiles exhibit exceptional corrosion resistance, a vital characteristic for automotive applications routinely encountering exposure to various chemicals, moisture, and harsh environments. This corrosion resistance ensures the long-term dependability and durability of the profiles, ultimately reducing maintenance expenses and prolonging the lifespan of automotive components. Moreover, FRP pultrusion profiles offer remarkable design flexibility, thereby facilitating the formation of intricate shapes and geometries that can be customized to meet specific automotive requirements. This flexibility allows for the seamless integration of FRP profiles into numerous automotive components, including body panels, structural supports, interior trims, and suspension parts. Additionally, FRP pultrusion profiles demonstrate high fatigue resistance, a crucial aspect for automotive applications that involve repetitive loading and vibrations. The fatigue resistance of FRP profiles guarantees their enduring performance and aids in averting failures and breakdowns. Lastly, FRP pultrusion profiles are non-conductive, an advantageous attribute in automotive applications necessitating electrical isolation. This property obviates the necessity for supplementary insulation and mitigates the risk of electrical failures and short circuits. All in all, the amalgamation of lightweightness, robustness, corrosion resistance, design flexibility, fatigue resistance, and electrical non-conductivity renders FRP pultrusion profiles suitable for diverse automotive applications, thereby contributing to enhanced performance, fuel efficiency, durability, and safety within the automotive industry.

- Q:Can FRP pultrusion profiles be used in telecommunications applications?

- Telecommunications applications can utilize FRP pultrusion profiles, which offer a range of advantages that render them suitable for such infrastructure. To begin with, these profiles possess the desirable combination of being lightweight and strong, making them an excellent choice for supporting antennas, cable trays, and equipment racks. Their high strength-to-weight ratio enables easier installation and transportation while providing the necessary structural support. Moreover, FRP pultrusion profiles display corrosion resistance, a crucial characteristic for telecommunications applications. Given the exposure of telecommunications infrastructure to harsh environments like moisture, chemicals, and extreme temperatures, FRP's non-corrosive properties guarantee long-term durability and reliability, distinguishing it from traditional materials such as steel or wood. Additionally, FRP pultrusion profiles offer electrical insulation properties, which are vital in telecommunications applications. By not conducting electricity, they ensure safety in areas where electrical equipment is present. This feature prevents electrical interference and preserves the integrity of the telecommunications system. Furthermore, FRP pultrusion profiles can be customized to meet specific design requirements, as they can be manufactured in various shapes and sizes. This flexibility allows for the efficient design of telecommunications infrastructure, making FRP pultrusion profiles suitable for a wide range of applications within the industry. In conclusion, FRP pultrusion profiles prove to be well-suited for telecommunications applications due to their lightweight yet strong nature, corrosion resistance, electrical insulation properties, and customization possibilities. These attributes guarantee their reliability in supporting and protecting telecommunications infrastructure.

- Q:Can FRP pultrusion profiles be used in the construction of agricultural structures?

- Yes, FRP pultrusion profiles can be used in the construction of agricultural structures. FRP pultrusion profiles are lightweight, durable, and resistant to corrosion, making them suitable for various agricultural applications such as greenhouse framing, livestock enclosures, and storage sheds. They offer excellent strength-to-weight ratio and can withstand harsh environmental conditions, making them a reliable choice for agricultural construction.

- Q:Are FRP pultrusion profiles resistant to nitric acid?

- FRP pultrusion profiles are generally resistant to nitric acid. Nitric acid is a strong oxidizing agent and can corrode many materials including metals. However, FRP (Fiber Reinforced Polymer) pultrusion profiles are made of composite materials that are specifically designed to be resistant to various corrosive substances, including nitric acid. The corrosion resistance of FRP pultrusion profiles can be attributed to the combination of their reinforcing fibers, such as fiberglass or carbon fiber, and the resin matrix that binds these fibers together. The resin matrix used in FRP profiles is typically a thermosetting polymer, such as polyester or epoxy, which provides a protective barrier against corrosive substances. Nitric acid is known to attack metals, causing corrosion and degradation. However, FRP pultrusion profiles offer excellent resistance to nitric acid due to the inert nature of the composite materials used. The reinforcing fibers in FRP profiles do not react with nitric acid, and the resin matrix acts as a barrier, preventing the acid from reaching and corroding the fibers. It is important to note that the specific resistance of FRP pultrusion profiles to nitric acid may vary depending on the specific composition of the composite materials used and the concentration and temperature of the nitric acid. Therefore, it is always recommended to consult with the manufacturer or supplier of FRP profiles to ensure their compatibility with nitric acid in specific applications.

- Q:Are FRP pultrusion profiles resistant to chemicals used in oil refineries?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles are highly resistant to chemicals used in oil refineries. The composition of FRP profiles includes a combination of high-strength fibers, such as fiberglass, carbon fibers, or aramid fibers, embedded in a polymer resin matrix. This unique construction provides excellent resistance to a wide range of chemicals, including those commonly found in oil refineries. The polymer resin matrix used in FRP profiles can be carefully selected to withstand harsh chemical environments. For instance, vinyl ester or epoxy resins are often used in the manufacturing of FRP profiles for oil refinery applications due to their superior chemical resistance properties. Moreover, FRP pultrusion profiles are inherently corrosion-resistant, unlike traditional materials like steel or concrete, which can deteriorate when exposed to aggressive chemicals found in oil refineries. This corrosion resistance ensures the long-term durability and reliability of FRP profiles in such environments. Additionally, FRP profiles offer several other advantages in oil refinery applications, including high strength-to-weight ratio, electrical insulation, non-magnetic properties, and ease of installation. These characteristics make FRP pultrusion profiles an ideal choice for various structural, piping, and equipment applications within oil refineries. However, it is essential to consider the specific chemicals and concentrations involved in a particular oil refinery application. While FRP profiles generally exhibit excellent resistance to a wide range of chemicals, there might be certain highly concentrated or specialized chemicals that could potentially affect their performance. In such cases, it is advisable to consult with FRP manufacturers or experts who can provide tailored solutions to meet the specific chemical resistance requirements of the oil refinery.

- Q:Are FRP pultrusion profiles fire resistant?

- Yes, FRP pultrusion profiles are fire resistant.

- Q:What are the circumstances in which the pultrusion should be performed?

- The roving yarn assembly in yarn frame, yarn unwinding through a series of guide roller and cluster grid plate, roller set, enter the resin impregnated resin impregnated yarn groove. Then through the pre forming die, the die is required according to the shape of products and configuration in the guiding device. The mold after discharge excess resin and bubbles into the cold. Cold mold cooling by cooling water, so that the resin viscosity, reduce the loss, and finally into the mold, the fiber reinforced material and resin molding in mold curing, and then the traction device is pulled, cut into required length of products by cutting device.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

FRP Grating/ Fiberglass Solid Grille/Water Resistance Steel Grating with Various of Colors

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords