Frp Corrugated Roofing Color Coated Metal Roof

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m

- Supply Capability:

- 50000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

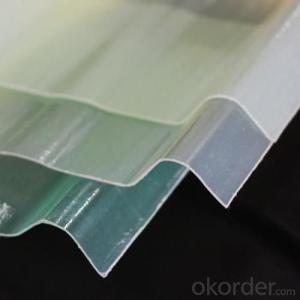

PRODUCT DESCRIPTION

Fiberglass corrugated sheet is usually used in construction site as protecting facility. It is dagarous for workers in building site since you never know if there is something hard drop down from the high area. So corrugated sheet is installed for preventing the stuff dropping down to hurt people.

FRP GRP Fiberglass Glassfiber Corrugated Roofing is a patent of our company, not like other FRP products, it is produced without yarn, instead, we use mat only. Therefore, the corrugated sheet is more strong in both horizontal and vertical direction.

Fiberglass corrugated sheet is usually used in construction site as protecting facility. It is dagarous for workers in building site since you never know if there is something hard drop down from the high area. So corrugated sheet is installed for preventing the stuff dropping down to hurt people.

Besides, it could also applied as the roof of the constructions.

FEATURES

a. anti-corrosion, non-rusty

b. lightweight and high strength

c. anti-flammable

d. anti-fatigue

e. anti-slippery and safety

f. anti-ageing

g. easy to installation and maintenance

h. excellent electromagnetism property

SPECIFICATIONS

Name: | FRP Roofing |

Material: | Fiberglass |

Width: | 880mm/1050mm |

Effective width: | 800mm/960mm |

Wave length: | 160mm |

Wave height: | 30mm |

Pitch: | 220mm |

Thickness: | 3/2.5mm |

Length: | Customized but must be a multiple of wave pitch |

Color: | Purplish Red, Brick Red, Grey, Green, Blue or customized |

Application: | House, villa, pavilions, industrial plants, large warehouses, supermarkets, stadiums etc |

MOQ: | 1000 Square meter |

PICTURES

- Q:Can FRP roofing panels be used for pergolas?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be used for pergolas. FRP panels are lightweight, durable, and resistant to weather elements, making them an ideal choice for pergolas. They provide protection from the sun and rain while allowing natural light to pass through, creating a comfortable outdoor space. Additionally, FRP panels are easy to install and maintain, making them a popular option for pergola construction.

- Q:Are FRP roofing panels resistant to damage from hail or sleet?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels are typically resistant to damage from hail or sleet. The strong and durable nature of FRP materials helps them withstand the impact of hailstones or sleet without significant damage. However, the level of resistance can vary depending on the thickness and quality of the panels, so it is advisable to choose panels specifically designed for hail resistance if living in an area prone to hailstorms.

- Q:Can FRP roofing panels be used for patio covers?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be used for patio covers. FRP roofing panels are lightweight, durable, and resistant to various weather conditions, making them an ideal choice for patio covers. They are designed to withstand UV rays, extreme temperatures, and moisture, ensuring long-lasting performance. Additionally, FRP panels come in a variety of colors, styles, and sizes, allowing you to choose the perfect option for your patio cover. They are easy to install, low maintenance, and can provide a beautiful and functional addition to your outdoor space.

- Q:Are FRP roofing panels resistant to environmental pollutants or acid rain?

- Yes, FRP roofing panels are highly resistant to environmental pollutants and acid rain. The composition of these panels, which includes fiberglass and a protective resin coating, provides excellent protection against the harmful effects of pollutants and acid rain. This makes FRP roofing panels a durable and reliable choice for withstanding environmental challenges.

- Q:Do FRP roofing panels require any special tools for installation?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels typically require some special tools for installation. These tools may include a power drill with appropriate bits, a circular saw or a jigsaw for cutting the panels to size, a tape measure, a level, a ladder or scaffolding for accessing the roof, a caulking gun for applying sealant, and roofing nails or screws for securing the panels to the roof structure. Additionally, a safety harness and appropriate personal protective equipment, such as gloves and safety glasses, should be used during the installation process. It is important to consult the manufacturer's instructions and guidelines to determine the specific tools required for the installation of FRP roofing panels, as the requirements may vary depending on the panel design and installation method.

- Q:Are FRP roofing panels resistant to warping or sagging from prolonged exposure to heat?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels are highly resistant to warping or sagging from prolonged exposure to heat. FRP panels are specifically designed to withstand extreme temperatures and maintain their structural integrity. The fiberglass reinforcement within the panels provides exceptional strength and stability, making them highly resistant to thermal expansion and contraction. This means that even under intense heat, FRP roofing panels will not warp or sag, ensuring long-lasting performance and durability. Additionally, FRP panels have excellent dimensional stability, which further prevents any deformation or distortion caused by heat exposure. Therefore, FRP roofing panels are a reliable choice for applications that require resistance to warping or sagging due to prolonged exposure to heat.

- Q:Do FRP roofing panels have good insulation properties?

- Yes, FRP roofing panels generally have good insulation properties. They are known for their high thermal resistance, which helps in keeping the interior of buildings cooler in hot weather and warmer in cold weather. Additionally, FRP panels provide excellent resistance to heat transfer and can effectively reduce energy consumption, making them an ideal choice for insulation purposes.

- Q:How do FRP roofing panels perform in terms of insulation?

- FRP roofing panels have relatively low insulation properties compared to other roofing materials. However, they still provide some level of insulation and can help reduce heat transfer between the interior and exterior of a building.

- Q:Do FRP roofing panels require a specific type of ventilation?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels do require a specific type of ventilation. Proper ventilation is essential to ensure the longevity and performance of FRP roofing panels. FRP panels tend to expand and contract with temperature changes, and without proper ventilation, this can lead to warping, cracking, or even failure of the panels. The specific type of ventilation required for FRP roofing panels is known as ridge ventilation. Ridge vents are installed at the peak of the roof to allow hot air to escape from the attic or the space under the roof. This type of ventilation creates a continuous flow of air, preventing the buildup of heat and moisture that can damage the FRP panels. In addition to ridge ventilation, it is also important to have proper soffit or eave vents to allow fresh air to enter the attic or space under the roof. This creates a balanced airflow that helps to regulate temperature and moisture levels, further protecting the FRP roofing panels. It is worth noting that the specific ventilation requirements may vary depending on the specific manufacturer's recommendations or local building codes. Therefore, it is always advisable to consult the manufacturer's guidelines or seek professional advice to ensure that the FRP panels are properly ventilated for optimal performance and longevity.

- Q:Can FRP roofing panels withstand high winds?

- Yes, FRP roofing panels are designed to withstand high winds. They are made from a durable and strong material that can resist the force of strong winds, making them a reliable choice for areas prone to high wind conditions.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Frp Corrugated Roofing Color Coated Metal Roof

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m

- Supply Capability:

- 50000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords