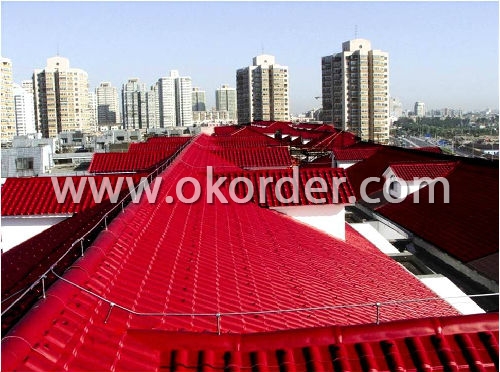

FRP Corrugated Lighting Sheet in Different Colors

- Loading Port:

- Qing Dao Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1000M2 m²

- Supply Capability:

- 3000 M2 Per Day m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Good Quality FRP Corrugated Lighting Sheet

FRP Sheet made by serial machinery of FRP sheet have the advantages of smooth surface, even thickness, high impact strength, good weather resistance as well as high productivity. It is the best materials for the surface panels of top grade refrigeration vehicles for its excellent properties of heat and moisture insulaiton.

Thickness:0.8mm、1.0mm、1.2mm、1.5mm、2.0mm、2.5mm、3.0mm;

Width:1000mm、1200mm;

Color:Clear/Lake Blue/Sky Blue/Light Green/ Opal;

Length:30m/rolling

Applications of Good Quality FRP Corrugated Lighting Sheet

They are applied to steel structure workshops, warehouses, weather sheds, car parks, weather corridors, lighting sheds, sun sheds,

greenhouses, etc. They are the ideal materials for the choices of enterprises and institutions.

The necessary characters of high quality FRP Corrugated Lighting Sheet:

1. small air bibbles

2. no bubbles

3. anti-aging resin

4. high property upper film(or gelatum)

5. high quality non-alkali fiber-glass

6. consistent high light transmission

7. high chemistry corrosion resistance

8. high anti-ultraviolet property

9. even thickness

Package& Delivery of Good Quality FRP Corrugated Lighting Sheet

Wooden pallet,according to custom requires.

Technological Parameters of Good Quality FRP Corrugated Lighting Sheet

Density 1.5 g/cm3 Tensile strength 100Mpa

Fiber content >25% Bending strength 160Mpa

Curing degree >82% Impact ductility 135 KJ/㎡

Gel Coat Thickness 20-150μm Thermal conductivity 0.158 W/m.k

Weathering film thickness 20-30μm Thermal expansivity 2.2X10-5mm/mm/℃

Light transmissivity 60-85% Water absorption 0.32%/24hr

Suitable temperature -40℃-120℃ UV Rate 99.9%

Thickness:0.8mm、1.0mm、1.2mm、1.5mm、2.0mm、2.5mm;

Color:clear, sky blue,lake blue & opal;

Length:cut as per customers' requirements on the condition that it is suitable for transportation

Pofiles:over 10 profiles for you choice at present:For detailed profiles please visit:820-205, 840-210, 760-380, 950-237,930-79, 812-203, 406-203 and so on

- Q:10mm thick transparent light board how much money a square ah

- FRP lighting panels and PC sun panels in the performance, there are nine differences, the following specific analysis:

- Q:FRP lighting board is what and the common classification and specification analysis

- FRP lighting plate commonly known as FRP, also known as transparent tile, and steel structure is supporting the use of lighting materials, which is mainly composed of high-performance film, reinforced polyester and glass fiber composition, which on the film to play a very good anti-UV anti-static The role of anti-ultraviolet light is to protect the FRP lighting board of the polyester is not yellowing, premature loss of light transmission characteristics

- Q:I am a FRP lighting board, XPS insulation board sales staff, how to find this aspect of the procurement information? I am a novice!

- Features: a high strength, long life of 15 - 20 years or more; b appearance smooth, light transmission rate of 85% or more; c corrosion resistance, anti-aging, anti-ultraviolet, can filter out 90% of the sun UV; d products Stability, strong, -30 ℃ -130 ℃ between the product without any impact E According to customer needs can choose flame retardant, and other special performance Specifications and flexible size, the product can produce arbitrary waveforms and plates, steel construction is the best lighting products Is the chemical industry, metallurgical industry building anti-corrosion preferred products Order: Yehua

- Q:Mingtang place with a transparent tile made a shed line okay

- What is the lighting tile? There are two types of light-emitting tiles, the shape of a wave-shaped, ladder, round, pyramid type, there is a frosted and flat-mounted microwave, different shapes, his lighting effects are different, the current market two materials , Divided into PC material and FRP material (glass fiber), which PC material of the lighting tile his light transmission to be strong, but he also has shortcomings, he can not acid and alkali, for chemical products where the place is not suitable, Another FRP (glass fiber) and the PC material is just the opposite nature of his translucent no PC is good, but he can be acid and alkali, suitable for the place where there are chemicals

- Q:What is the lighting board, and what is the difference between the sun, that by the longer time

- FRP lighting panels and PC sun panels in the performance, there are nine differences, the following specific analysis:

- Q:Does the lighting plate be so hot for a long time?

- Lighting board for a long time sun no poison,and it will be along long time.

- Q:Look at the effect should be more symmetrical, should not be scattered, not easy to fade the kind of problem added: is the epoxy resin, if you do not use color paste cream, you can use paint? Do not know can not blend with the resin? -? More

- Look at the effect should be more symmetrical, should not be scattered, not easy to fade the kind of problem added: is the epoxy resin, if you do not use color paste cream, you can use paint? Do not know can not blend with the resin? -? More

- Q:Pvc lighting tile and pc lighting tile and frp lighting tile difference

- In the outdoor natural light of the lower early morning, evening, and the summer sun height angle is high, the effect is particularly evident

- Q:The load - bearing capacity of glass steel tiles. There is no higher strength, can hold up people stand up, move around. I was used in the roof of the steel shed.

- If the Master, I can only give you the way is made of laminated plastic glass, but its weight is greater, if the steel beam has been done, please review the strength and stability of the beam I hope my answer is helpful to you

- Q:FRD lighting board and PC board which is good? What are the advantages and disadvantages? Thank you!

- PC sunshine board and FRP lighting tile difference First, the material composition Description

1. Manufacturer Overview |

|

|---|---|

| Location | Guangdong, China |

| Year Established | 2006 |

| Annual Output Value | Below US$ 1 Million |

| Main Markets | 20.00% Mid East 15.00% Northern Europe 15.00% North America 12.00% Eastern Asia 10.00% Africa 9.00% Eastern Europe 8.00% Southeast Asia 4.00% Oceania 3.00% Western Europe 2.00% Southern Europe |

| Company Certifications | ISO 14001:2004 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | FoShan |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English; Chinese; Korean |

| b)Factory Information | |

| Factory Size: | 10,000-30,000 square meters |

| No. of Production Lines | Above 3 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | High; Average |

Send your message to us

FRP Corrugated Lighting Sheet in Different Colors

- Loading Port:

- Qing Dao Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1000M2 m²

- Supply Capability:

- 3000 M2 Per Day m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords