FRP Centrifugal Fan

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The fan is to rely on the input of mechanical energy, to increase the gas pressure of the gas feed side of the machinery. FRP centrifugal fan is made of glass fiber reinforced plastic material made of fans, also known as anticorrosion centrifugal fan.

Features

With strong corrosion resistance, long life, stable operation and other characteristics.

General FRP centrifugal fan can be used in the case of corrosive gases, emission of corrosive gases. It is not allowed to transport gas with viscous material, contained in dust and hard particles are less than or equal to 150mg / m3, the gas temperature is less than or equal to 60 degrees, the relative humidity is less than or equal to 100%. Not suitable for high temperature place FRP centrifugal fan.

Use

Widely used in the case of containing corrosive gas chemical, electroplating, oxidation, power plants, laboratories, circuit boards, environmental protection equipment.

Centrifugal fan and turbine compressor works basically the same, but due to the low gas flow rate, pressure changes little, generally do not need to consider changes in the specific volume of gas that the gas as incompressible fluid handling.

Centrifugal fan can be made righthanded and lefthanded two types. To face from the motor side, the impeller rotates clockwise rotation of the fan called right, rotate counterclockwise, called L.

Centrifugal fan is based on the principle of potential energy is converted to kinetic energy, the use of highspeed rotation of the impeller of the gas to accelerate, then slow down, change the flow, so that the kinetic energy is converted into potential energy (pressure). In the singlestage centrifugal fan, the gas enters from the axial impeller, changing the gas flow through a radial impeller, and then into the diffuser. In the diffuser, the gas flow direction changes caused by the deceleration, the decelerating effect of the kinetic energy is converted into pressure energy. Increased pressure occurs mainly in impeller, followed by the process occurs in the diffuser. In a multistage centrifugal fan, the air flow into the next with a reflux allows the impeller to produce higher pressures.

- Q:Fence material outside the plastic inside is iron or steel this material called

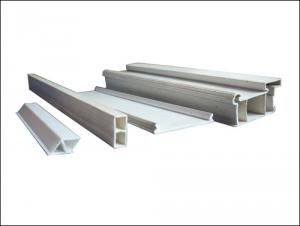

- Generally refers to steel profiles. Plastic profiles are used for the production of doors and windows with PVC profiles, as early as the late 1950s has been in Germany, China began in 1983 from the beginning of the 20th century, the late 90s began universal application. Because simply use PVC profiles processing doors and windows strength is not enough, usually in the cavity to add steel to enhance the stability of doors and windows, so the profile of the steel interior made of plastic doors and windows are often called steel doors and windows. With the extensive use of steel doors and windows, PVC profiles for the production of steel doors and windows are commonly known as steel profiles.

- Q:Will the model of steel profiles (such as 88-type extrusion profiles, 80 extrusion profiles) is based on what to develop ah

- Strictly speaking, refers to the width of the bottom of the window frame profile. 88 is that the bottom of the frame width of 88 mm. And some profiles are not absolutely accurate, take the approximate value

- Q:Specification for steel profiles

- Before 50, did not use 40 or 38, 10 years ago I have done spliced steel, and now who is willing to splicing ah. But really want to splice, and now have steel can also be spliced.

- Q:Plastic doors and windows and plastic windows do not like?

- According to the material plastic doors and windows can be divided into PVC plastic doors and windows and glass fiber reinforced plastic (FRP) doors and windows. The following are the same as the " 1, PVC plastic doors and windows 1) In all kinds of building windows, PVC plastic windows in saving energy production profiles, recycling of recycled materials and the use of energy consumption has a prominent advantage in the insulation and energy saving has excellent performance and low cost. The following are the same as the " 2) In order to increase the rigidity of the window, in the window frame, sash, the tread profile of the force bar, should be based on the strength of the wind pressure design and other requirements to determine what kind of reinforced steel. The following are the same as the " 3) Coextrusion of UPVC resin with colored polymethyl methacrylate (PMMA) or acrylonitrile-styrene-acrylate copolymer (ASA), as well as coating on white profiles, can be coated with a variety of textures and A variety of surface color decorative effect. In addition, UPVC resin powder is also added to the pigment mixture extrusion of the body dyeing technology. But there are still different views on this technology, it should be particularly careful in the selection, to check the kind of profiles by artificial accelerated aging test after the color changes. It is recommended to coat the color film with the color film to improve its weatherability.

- Q:The main features of steel profiles

- In the building construction is mainly used for sliding, sliding doors and windows, fence, pipe and ceiling material applications, through the new process is also widely used in automotive engine protection board, not only light weight, and good toughness, with just fine Nature, and sometimes also known as alloy steel.

- Q:Plastic steel window profile specifications models which

- Plastic window is a form of window that is actively promoted by the state in the mid-1990s after the wood, iron and aluminum windows. Because of its low price, performance and price is better, is still widely used.

- Q:The development of steel profiles

- China's steel production capacity has reached 5 million tons / year. Most manufacturers can not fully play the capacity, there is a serious overproduction and homogenization of competition. China's steel profiles common national standard is GB / 8814-2004, access to national inspection-free enterprises are also referred to this standard production. Different from Europe and the United States, China's single type of profiles, the market is the bulk of the 60MM Pingkai doors and windows series of profiles and 80MM push-pull series of doors and windows profiles. The above two specifications account for more than 80% of the total consumption.

- Q:The difference between steel and aluminum alloy profiles

- Plastic windows are easy to weather, aluminum alloy will not. If you want to be insulated when you do windows with double glass

- Q:What is the steel profile?

- The profile is still visible when the window is still visible

- Q:Plastic profile brittle extrusion process unreasonable reasons

- Excessive or insufficient material This is related to the process temperature setting and feeding ratio. The temperature setting is too high to cause the material to be plasticized. Some of the components with low molecular weight in the component will decompose and evaporate. The temperature is too low. Fully welded, the molecular structure is not strong, while the feed ratio is too large cause the material heating area and shear increases, the pressure increases, easily lead to plastic; feeding ratio is too small material heating area and shear reduction, Resulting in less plasticized, whether it is plastic or plastic surgery will cause plastic profiles crisp cutting collapse phenomenon.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

FRP Centrifugal Fan

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords