Frosted glass plate fracture endurance,PC sheet

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 30000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of PC Frosted Sheet Description:

PC frosted panel board face uniform distribution of fine particles, is in the endurance plate manufacturing technology, on the basis of changing part of the mould and process, make the product of the physical changes in surface morphology, which caused by plate surface structure change and optical performance and changes in vision and feeling. PC frosted glass plate mechanical properties, electrical properties, flame retardant performance, such as ultraviolet resistance and endurance plate is consistent, different appearance mainly morphology and optical properties, by its own surface concave and convex shape, density of concave and convex and size made through different sheet of light scattering and transmission to like not through, like see a blur. Apply to the bathroom, screen, and furniture, etc.

In addition, the PC frosted slabs have the function of the diffuse light, can make the light distribution more uniform, light penetrates the PC frosted plate after more downy, foil a warmth, refined flavor, commonly used for lighting and other fields.

2.Main Features of PC Frosted Sheet:

Weather resistance,impact resistance.

Flame retardant,temperature resistance

Potable,Sound insulation.

3.PC Frosted Sheet Specification:

| Width(mm) | Thickness(mm) | The minimum bending radius | Color | |

| 1220 | 2.0 | 360 | Blue | |

| 1560 | 2.4 | 430 | Tea | |

| 1820 | 3.8 | 680 | White | |

| 2100 | 4.0 | 720 | Green |

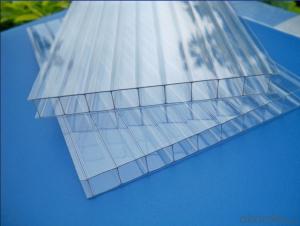

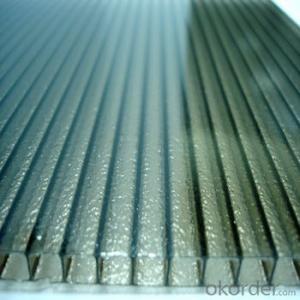

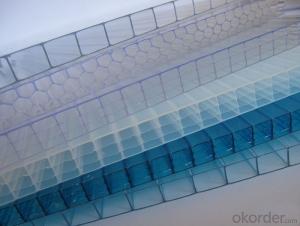

4.PC Frosted Sheet Images:

- Q:Can the stencils be made in the bathroom?

- PC particle board characteristics 1, the surface of the plate can reflect the direct light on the plate of direct exposure, after this treatment can reduce the sunlight penetration. 2, the surface of the board can increase the surface area, while increasing the heat, can extend the service life of the plate. 3, the surface of the plate per square meter distribution of 15,000-18000 pieces of anti-diamond-type particles, reflection, refraction effect can enhance the blocking capacity.

- Q:PC sun board life years?

- 10 years warranty is 10 years, light transmission rate decreased by 6%, yellow index change is less than 6. This is the plastic is not too much of the aging indicators. Means that after 10 years of good sunshine board physical mechanical properties decline is very little, basically will not affect the use of sex. Foreign pc sun panels are basically used for more than 20 years. Good pc sunshine board is not like the above answer "is to provide", rely on equipment, technology, raw materials, testing means. Generally speaking, imported equipment uv co-extruded layer thickness is more uniform, the service life will be longer.

- Q:Lighting board and sunshine board which is good?

- Sunshine board heat insulation effect is good but not weathering a hot one frozen to die because he is a PC. Lighting board lighting good insulation effect is poor, not afraid of acid and alkali, weathering and more useful life.

- Q:Company pc sunshine board how to solve the problem

- The use of PC on the buckle, aluminum alloy buckle up and down, this method of dealing with a little higher cost of seams, but simply can bear, but if it is bow high bow stent device is difficult.

- Q:Sunshine board price per square meter, PC sun board how much money a square meter

- Thickness 16mm - 40mm, the price is generally 80 yuan - 260 yuan / ㎡, this interval thickness of the PC sun panels generally use less, but also a variety of shapes. ? Global PC sunshine board prices are different.

- Q:Can the sun board cover the bedroom?

- Sun panels can cover the bedroom, the sun board mainly by the PC / PET / PMMA / PP material production. English is sunlight, referred to as hollow board, pc sun panels to polycarbonate as the main raw material manufacturing. Sunshine board in the mid-80s into the building materials quickly.

- Q:Project sun board price how much

- Thickness 16mm - 40mm, the price is generally 80 yuan - 260 yuan / ㎡, this interval thickness of the PC sun panels generally use less, but also a variety of shapes. Global PC sunshine board prices are different.

- Q:What are the differences between plastic endurance boards and sun panels?

- PC board in two kinds - solid for the endurance board, hollow for the hollow board or sun panels.

- Q:Where the PC stamina board and the sun board sell more price is also cheaper

- PC sheet prices from high to low are all very cheap to have a lot, you have a lot of expensive, the key depends on what you want quality, and said quality generally refers to the service life, you want to use a few years warranty PC Sun board. The price from 20 to 70 yuan, from 5 to 10 years warranty.

- Q:What is the difference between the PC and the PC board?

- Two products are the same material, but the production process is not the same, the price is generally the same circumstances

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Frosted glass plate fracture endurance,PC sheet

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 30000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords