Frame-Connected Scaffolding with Resonable Structure

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 100000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

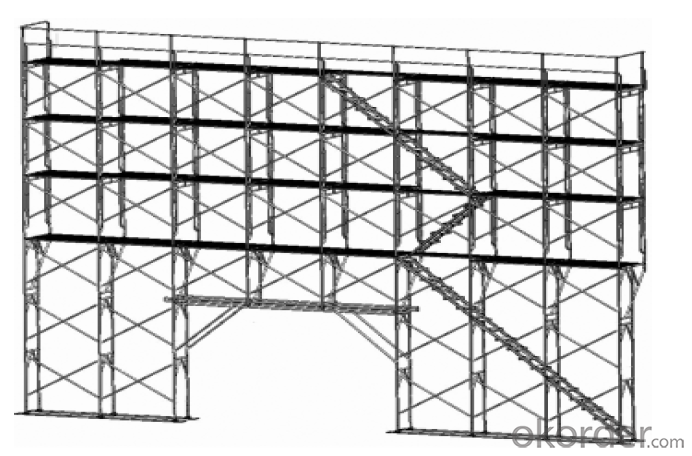

1. Structure of Frame-Connected Scaffolding

Presented like a shape of door , Frame-connected Scaffolding includes main frame, horizontal frame, cross brace, stage board and adjustable base. In order to display frame with couple system enough, good performance of stability ,firm structure of the whole, easy and fast to assemble and dismantle without any tools, safe working at height especially, and it is ideal material for construction engineering.

It can be widely used for industrial and civil construction and maintenance, such as workshop, large gymnasium, conference& exhibition center conversation, billboard, market, dock, tunnel, subways, etc. used for mobile working platform installation of electrical & mechanical engineering, ship repair and other decoration engineering, for building temporary stand ,with simple roof frame, frame-connected Scaffolding can from temporary dormitory, depot and work shed.

2. Main Features of Frame-Connected Scaffolding

.Reasonable structure, simple assembly, quick operation, safety& reliability.

.Easy to transport and knock down, high efficiently, save massive manpower and resource

.Easy to carry and operate with the weight about 20kg/p

.Assembly& disassembly with hands only to improve the efficiency highly, frame-connected scaffolding of assembly &disassembly saves half of the time than fasten steel-pipe scaffolding, and two third of the time than bamboo scaffolding.

.Widely usage, reasonable and practical, low aggregate cost.

3. Frame-Connected Scaffolding Images

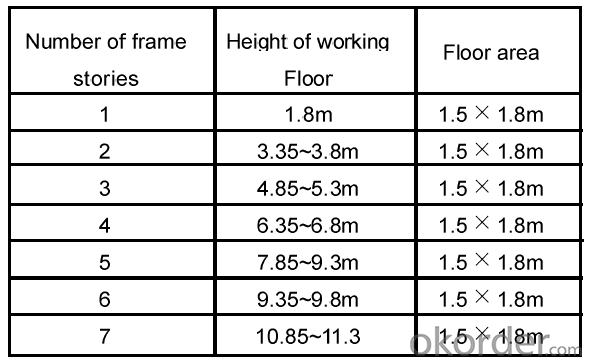

4. Frame-Connected Scaffolding Specification

.Maximum breaking load: 22.2t

.Safe working loads on jack components(safety factor:3.5)

5. FAQ of Frame-Connected Scaffolding

1) What can we do for you?

We can ensure the quality of the vinyl banner and avoid extra expenses for customers.

.We can provide you the professional design team.

.We can provide fashionable and newest styles for you.

.We can design the artwork for you.

. Please feel free to customize.

2) What promises can be done by us?

. If interested in Frame-Connected Scaffolding, please feel free to write us for any QUOTE.

. If printing required, please advise asap because the whole set need much more time to complete.

. Please DO check goods when courier knocks your door and contact us asap if any issue.

3) What about of our after-sale service?

. Response will be carried out in 24hours after receiving any complain or request.

. Frame-Connected Scaffolding cost can be refund after order is confirmed.

. If the products are not based on the requirements, there will be the relevant compensations made for you.

4) What about the package and shipping time?

.Packing: As Customer's Requirements

.Shipping: We have various shipping ways for our customers, such as express which including TNT, DHL, FEDEX, UPS, EMS, etc. ; by air/ sea, and we are VIP of these express.

.Shipping time:

Normally small orders, it just 10-15 business days to arrive your hand; When comes to the customs declaration, it may need 7 days.

Other mass qty of Frame-Connected Scaffolding, we send them out by sea or by air to sea port or air port to save some shipping freight for our customers. By ocean, it may need 45~60days, by air, it may need 25~40days.

- Q:What are the different load rating classifications available for steel tube couplers?

- Steel tube couplers offer various load rating classifications to ensure the secure and efficient connection of steel tubes in different applications. The Standard Load (SL) classification is one of the most commonly used classifications. It is suitable for general construction purposes and can handle low to moderate load-bearing tasks. SL couplers are denoted by a numeric value indicating their maximum load capacity in kilonewtons (kN). For more demanding applications, the Heavy Duty (HD) load rating classification is available. HD couplers are specifically designed for industrial and infrastructure projects, capable of handling higher loads. They have a greater load capacity compared to SL couplers and are built to withstand more challenging conditions. Furthermore, Super Heavy Duty (SHD) couplers are designed for extremely high-load applications such as heavy machinery and large-scale infrastructure projects. These couplers possess the highest load capacity and are engineered to deliver maximum strength and reliability. It is essential to consider that load rating classifications may differ among manufacturers. Therefore, consulting the specific manufacturer's documentation and guidelines is crucial to ensure the appropriate selection and usage of steel tube couplers. Engineers and professionals should also take into account factors like the type of load, structural requirements, and safety standards when choosing the suitable load rating classification for their particular project.

- Q:How do steel tube couplers ensure the stability and safety of scaffolding structures?

- Steel tube couplers ensure the stability and safety of scaffolding structures in several ways. Firstly, steel tube couplers are designed to securely connect steel tubes together, creating a strong and rigid structure. These couplers are typically made from high-quality steel, which provides excellent strength and durability. By tightly connecting the steel tubes, the couplers prevent any movement or displacement of the scaffolding components, ensuring stability. Secondly, steel tube couplers have a wide range of designs and types, such as swivel couplers, sleeve couplers, and putlog couplers, among others. This variety allows for different scaffolding configurations and connections, enabling the construction of complex and versatile structures. The various types of couplers ensure that scaffolding components can be securely joined together at different angles and orientations, providing flexibility and adaptability when constructing scaffolding systems. Furthermore, steel tube couplers undergo rigorous testing and adhere to strict safety standards. They are manufactured to withstand heavy loads and various weather conditions, ensuring the safety of workers and materials on the scaffolding. The high-quality steel used in the production of couplers provides resistance against corrosion and other forms of deterioration, further enhancing the safety and longevity of the scaffolding structures. Additionally, steel tube couplers are easy to install and dismantle, allowing for quick assembly and disassembly of scaffolding systems. This ease of use reduces the risk of accidents during the construction or dismantling process, as it minimizes the time workers spend on scaffolding structures. Overall, steel tube couplers play a crucial role in ensuring the stability and safety of scaffolding structures. Their ability to securely connect steel tubes, versatility in design, adherence to safety standards, and ease of use make them an essential component in the construction industry. By using steel tube couplers, construction workers can confidently build scaffolding structures that are stable, reliable, and safe for everyone involved in the project.

- Q:i was wondering how much it hurt:)? i know people have different experiences but could you rate it out of ten?i was going to have it done the other day, i was with my friend and we just happened to walk past a piercing shop and she was like pushing me in there lmfao, but i wasn't too sure, plus i hadn't told my parents and they would have gone mental if i didn't tell them, and could you include a link of websites that do nice barbells for when its healed? thanks x

- helllo okorder wellll, there you go! need any other info just ask me (:

- Q:Can steel tube couplers be used in both tube and clamp and system scaffolding?

- Yes, steel tube couplers can be used in both tube and clamp and system scaffolding. The couplers are designed to connect steel tubes securely and effectively, allowing for versatile applications in different types of scaffolding systems.

- Q:What are the common industry standards or certifications for steel tube couplers?

- There are several common industry standards and certifications for steel tube couplers. Some of the most widely recognized ones include ISO 9001:2015 for quality management systems, ASTM International standards for materials and product specifications, and the American Welding Society (AWS) certifications for welding processes and procedures. Additionally, some specific certifications may be required for certain industries, such as the API 5CT for oil and gas applications or the ASME BPE for pharmaceutical and bioprocessing equipment.

- Q:What are the loads that can be sustained by the construction of fasteners?

- Aluminum-magnesium alloy apple and DELL most commercial and XPS series and alien full range of this is what I know

- Q:Can steel tube couplers be used in scaffolding projects with corrosive environments?

- In scaffolding projects with corrosive environments, it is possible to utilize steel tube couplers. However, it is crucial to carefully choose the appropriate steel type and implement proper protective measures. To combat corrosion, stainless steel couplers or galvanized steel couplers are commonly employed due to their superior resistance compared to regular steel. These couplers are specifically designed to endure the corrosive effects of substances like saltwater or chemicals that may exist in the surroundings. Moreover, augmenting the longevity of the couplers can be achieved by applying corrosion-resistant coatings or paints that act as a barrier. Regular inspections and maintenance are also essential to promptly identify any signs of corrosion and take necessary actions to prevent further damage.

- Q:Fixed set to build fastener steel pipe full of scaffolding 3 row What does it mean

- And the roof of the lightning protection is the internal lightning protection system of a whole, Caigang sandwich panels and the upper structure of the connection form (to prevent & amp; cold bridge & amp; quot; scene); color steel sandwich panel for The power of repeated exposure to heat Insulation material does not have the same frequency of noise barrier effect is not the same, impermeable to prevent the snow from the inside into the Caigang sandwich panels Snow is important to pass through the gap or node into the color steel sandwich panels To achieve the performance of anti-seepage, the need to use the sealing ring in the screw seal after the adoption of hiding-type flow, the overlap in the board with a sealant or riveting solution Because the roofing of metal sheet is varied, the sound insulation of Caigang sandwich panel is from the heavy public building to the sound insulation coefficient a 8% annual increase in the progress of Caigang sandwich panels after the installation of the roof without access port, steel structure with energy saving, environmentally friendly recyclable, Caigang sandwich board confidence that few people can see on the spot

- Q:Can steel tube couplers be used in scaffolding projects that require overhead protection or canopy?

- Yes, steel tube couplers can be used in scaffolding projects that require overhead protection or canopy. Steel tube couplers are commonly used in scaffolding systems to join and connect steel tubes together, providing a secure and sturdy framework for construction projects. These couplers are designed to withstand heavy loads and provide stability to the scaffolding structure. When constructing scaffolding with overhead protection or canopy, steel tube couplers can be used to connect the horizontal beams that support the protective covering. This allows for the installation of a solid and safe overhead structure that can provide shelter from weather conditions or protect workers from falling objects. Steel tube couplers are versatile and can be used in various scaffolding configurations. They can be easily attached and detached, allowing for quick assembly and disassembly of the scaffolding system. Additionally, these couplers are highly durable and resistant to corrosion, ensuring the longevity and safety of the scaffolding structure. It is important to ensure that the steel tube couplers used in scaffolding projects meet the required safety standards and regulations. It is recommended to consult with a qualified engineer or scaffold supplier to determine the appropriate type and size of steel tube couplers for the specific project requirements.

- Q:How are steel tube couplers tested for safety and compliance?

- Steel tube couplers are tested for safety and compliance through various methods. These may include non-destructive testing techniques such as visual inspections, magnetic particle inspections, and ultrasonic testing to detect any structural defects or weaknesses. Additionally, load testing is conducted to assess the coupler's ability to withstand specified loads and ensure it meets the required safety standards and compliance regulations.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Frame-Connected Scaffolding with Resonable Structure

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 100000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches