FR-PPR Fibreglass High-Powered Composite Pipe

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

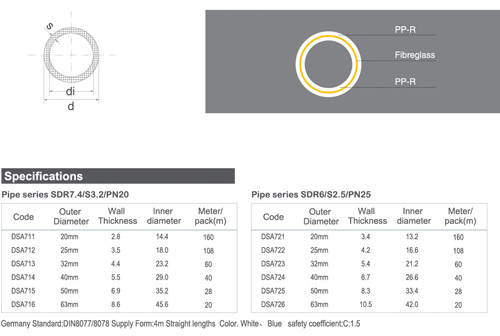

Our FR-PPR fibreglass high-powered composite pipe consists of three layers.

The middle layer adopts imported fabreglass strengthen material; the inner and the outer adopt imported raw materials.

Features:

1. FR-PPR pipe has higher strength, higher tenacity and lower expansion coefficient.

2. Non-deformation pipeline, more attractive appearance.

3. Resist high temperature, leak explosion proof pipe.

Advantages:

1. 1/3 lower coefficient of thermal expansion than common PPR pipe.

2. Thin, light, 20% flow capacity addition.

3. More compression resistance, longer service life.

4. Outdoor installation, widely applied fields.

5. Completely use imported raw materials, ensure product quality.

Applicaitons:

1. Distribution for cool and hot water.

2. Pipes for kinds of high-temperature and low-temperature heating system.

3. Pipes for heating and colling settings in solar energy system.

4. Connecting pipe for air-conditions.

Packaging & Delivery

Packaging details: weaving bag

Delivery detail: 10-30 days

- Q:Are plastic pipe fittings suitable for food processing industries?

- No, plastic pipe fittings are not suitable for food processing industries due to the risk of chemical leaching and contamination.

- Q:How do you remove a plastic pipe fitting?

- To remove a plastic pipe fitting, you can try using a heat gun or a hairdryer to warm up the fitting, making it more pliable. Then, you can gently twist and pull the fitting while applying some force to detach it from the pipe. If this doesn't work, you can use a fitting removal tool or a pair of pliers to grip the fitting tightly and twist it counterclockwise until it loosens and can be pulled off.

- Q:What are the connecting modes of steel wire mesh and plastic composite pipe?

- The connection installation group can be implemented, and the uniform welding can be carried out. The welding reliability is good and the strength and density are better than those of other connections. Keep the inner wall smooth, without affecting the flow area.

- Q:Are plastic pipe fittings resistant to moisture?

- Yes, plastic pipe fittings are generally resistant to moisture.

- Q:Are plastic pipe fittings compatible with electrofusion welding?

- Yes, plastic pipe fittings are compatible with electrofusion welding. Electrofusion welding is a commonly used method to join plastic pipes and fittings. It creates a strong, leak-proof connection by melting the pipe and fitting surfaces together using an electric current. Plastic pipe fittings, such as couplings, elbows, and tees, are specifically designed to be used with electrofusion welding techniques.

- Q:Can plastic pipe fittings be used for wastewater treatment facilities?

- Yes, plastic pipe fittings can be used for wastewater treatment facilities. Plastic pipe fittings are commonly used in wastewater treatment facilities due to their corrosion resistance, durability, and ease of installation. Additionally, plastic fittings are cost-effective and offer excellent chemical resistance, making them suitable for handling various wastewater treatment processes.

- Q:Are plastic pipe fittings resistant to high humidity environments?

- Yes, plastic pipe fittings are generally resistant to high humidity environments. They are designed to withstand moisture and humidity without corroding, which makes them a suitable choice for such conditions.

- Q:How are plastic pipe fittings manufactured?

- Plastic pipe fittings are typically manufactured through injection molding. This process involves melting plastic resin pellets and injecting the molten material into a mold cavity. Once the plastic cools and solidifies, the mold is opened, and the finished pipe fitting is ejected. Injection molding allows for the mass production of plastic pipe fittings with consistent dimensions and high precision.

- Q:Can plastic pipe fittings be used for underground cable protection?

- No, plastic pipe fittings are not suitable for underground cable protection. Underground cables require more durable and robust protection to withstand external forces and potential damage. Metal conduit or specialized cable protection systems are typically used for this purpose.

- Q:Are plastic pipe fittings resistant to pressure surges?

- Yes, plastic pipe fittings are generally resistant to pressure surges. They are designed to withstand and absorb sudden increases in pressure, minimizing the risk of damage or leaks. However, the resistance may vary depending on the specific type and quality of the plastic fittings used.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

FR-PPR Fibreglass High-Powered Composite Pipe

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords